Introduction

This article provides an in-depth exploration of rotameters.

Key topics covered include:

- Working Principle of Rotameters

- Different Types of Rotameters

- Applications and Advantages of Rotameters

- And more...

Chapter 1: Understanding the Fundamentals of Rotameters

This chapter examines the definition, design, and operation of rotameters.

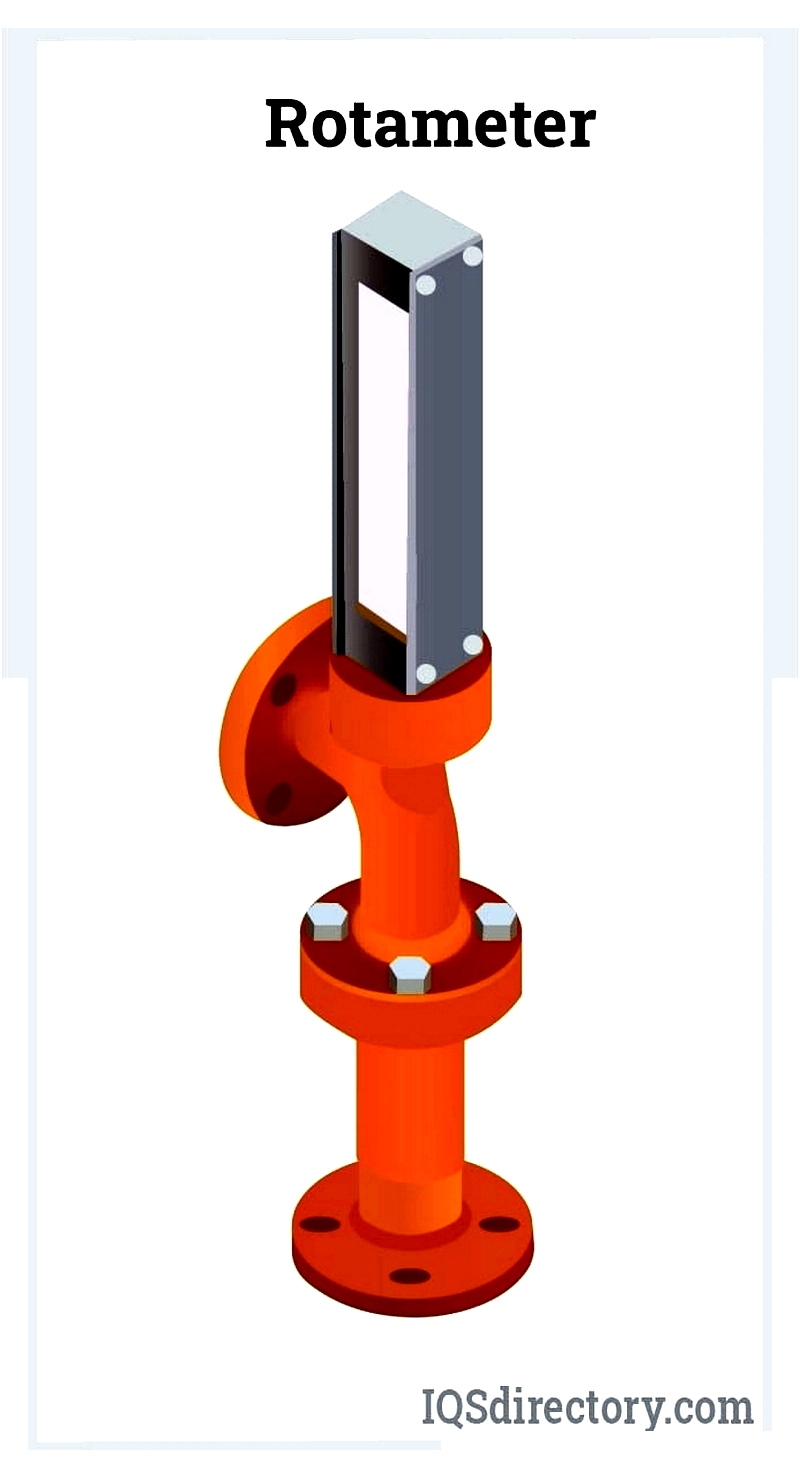

Defining a Rotameter

Rotameters measure fluid flow rates within a sealed tube over time. They are essential for chemical injection, dosing operations, and maintaining tank atmospheres. The device consists of a graduated glass tube containing a free-floating element that measures fluid flow.

As variable area flow meters, rotameters quantify the volume of liquids and gases passing through their conical tubes. When fluids or gases flow through, the float rises, increasing the passage area. Higher flow rates cause the float to ascend further within the tube.

Rotameters play a crucial role in pipeline purging by preventing blockages. They can provide alerts or electrical outputs to maintain continuous flow control.

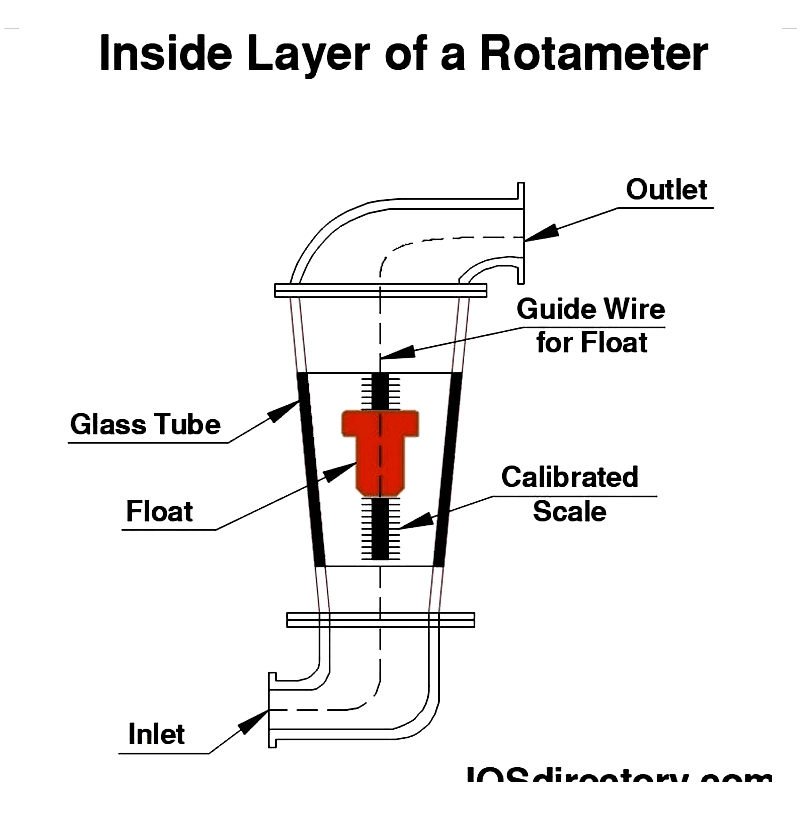

Rotameter Construction

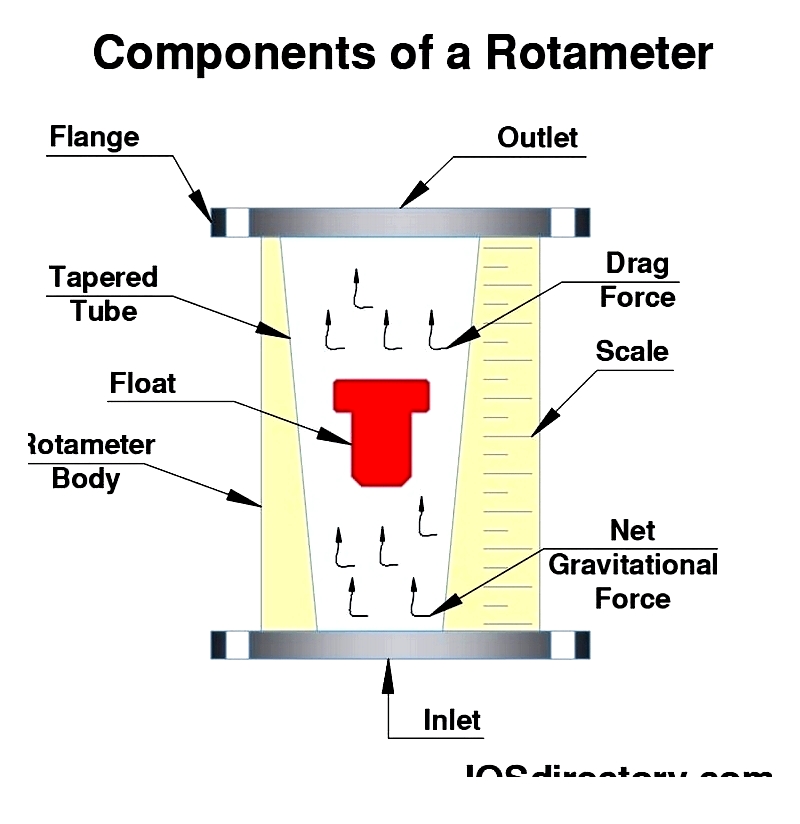

Rotameters feature a clear, vertically-oriented tapered tube that narrows at the bottom. This design stabilizes the float's position for consistent drop rates while minimizing flow disruption.

The glass tube is marked with a linear scale. Tube materials vary by application: plastics for general use, metals for opaque fluids, and glass for gases and clear liquids. metal tubes may use materials like lead or aluminum, while floats are typically stainless steel.

Operating Mechanism

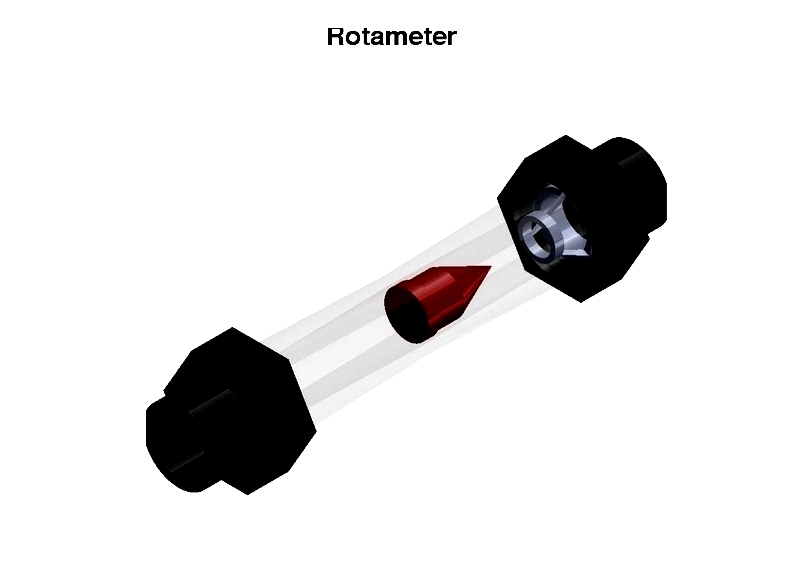

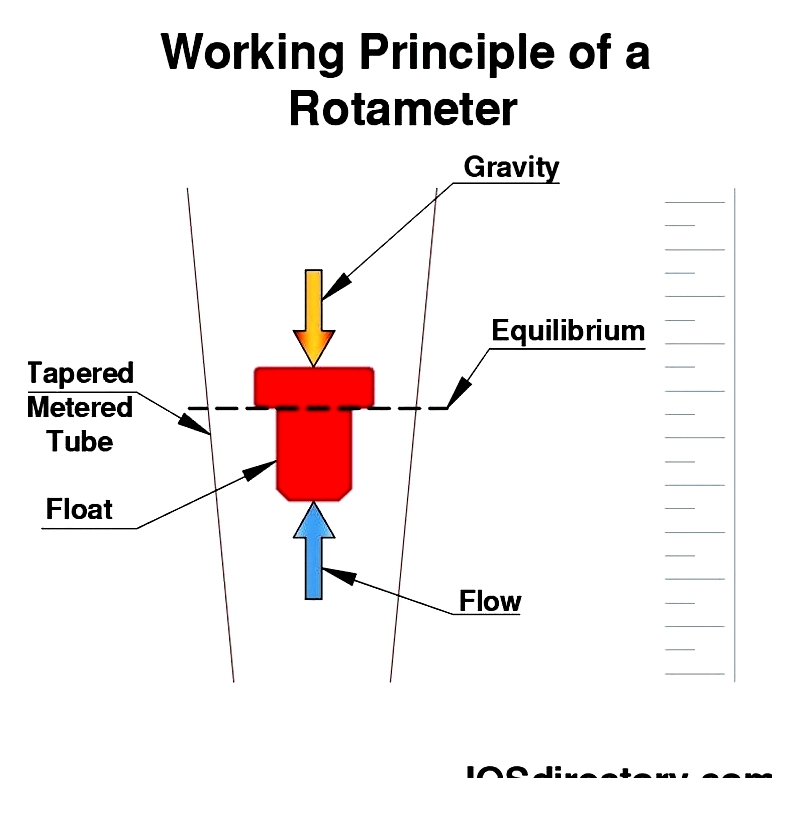

Fluid enters the tube's base and exits at the top, with the device measuring the flow. Without flow, the float rests at the tube's bottom, its diameter nearly matching the tube's internal width.

Fluid entry increases the annular flow space, causing the float to rise. It stabilizes when the pressure differential balances the float's weight. Higher flow rates increase this differential, lifting the float further until equilibrium is restored. The tube's markings indicate these pressure adjustments.

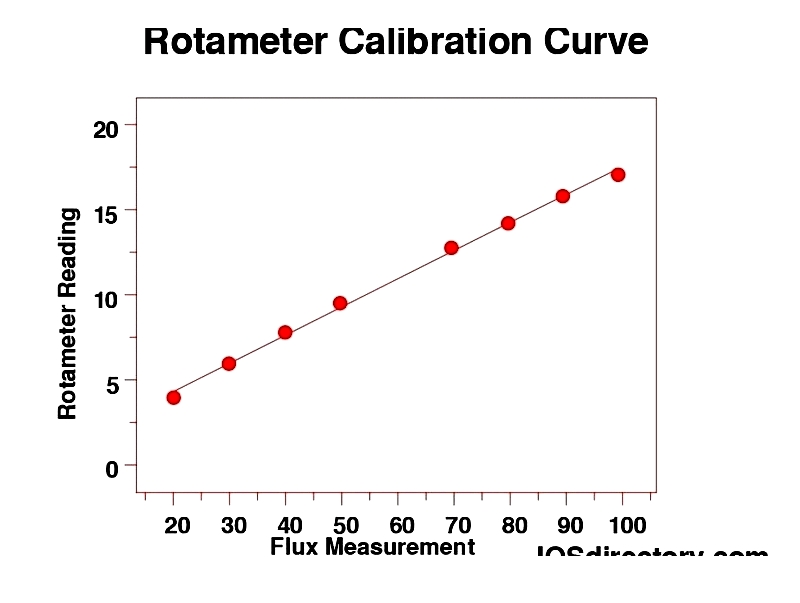

Calibration for specific gases or fluids under set conditions is critical. Flow ranges and measurement units are displayed on the meter. While manufacturers may not always provide detailed correction guidance, adjustments should account for flow variations.

Working Principle

Rotameter operation follows this formula:

Q=kA√GH

Where

Q = volumetric flow rate

k = constant factor

A = area between float and tube wall

g = gravitational force

h = pressure differential across the float

Rotameters are the most common variable area flow meters due to their advantages. Increased fluid flow raises the float until stabilizing forces reach equilibrium. The name originates from early designs with rotating elements responding to fluid pressure changes.

Manufacturers typically provide calibration data and measurement scales for common fluids like air and water, including tables and slide rules.

Characteristics

Linearity

The flow meter's area directly correlates with flow volume over time, producing uniform scales. Linearity may vary by approximately 5%.

Pressure Differential

Pressure loss across the float remains constant, though fitting friction increases differential pressure at higher flows.

Accuracy

Rotameters typically achieve ±2% scale accuracy. Extended scales and calibration improvements can enhance precision.

Capacity

Flow ranges span from 0.5 cm3/min (water) to 30 cm3/min (air).

Installation

No specific pipe length adjustments are required before or after installation.

Corrosive Liquids

Material-compatible rotameters accurately measure corrosive fluids like oil and sulfuric acid.

Pressure Loss

Wider-gauge floats minimize resistance while maintaining accuracy in low-pressure flow management.

Summary

Rotameters offer simplicity, affordability, and ±2% accuracy with user-friendly linear scales.

Components

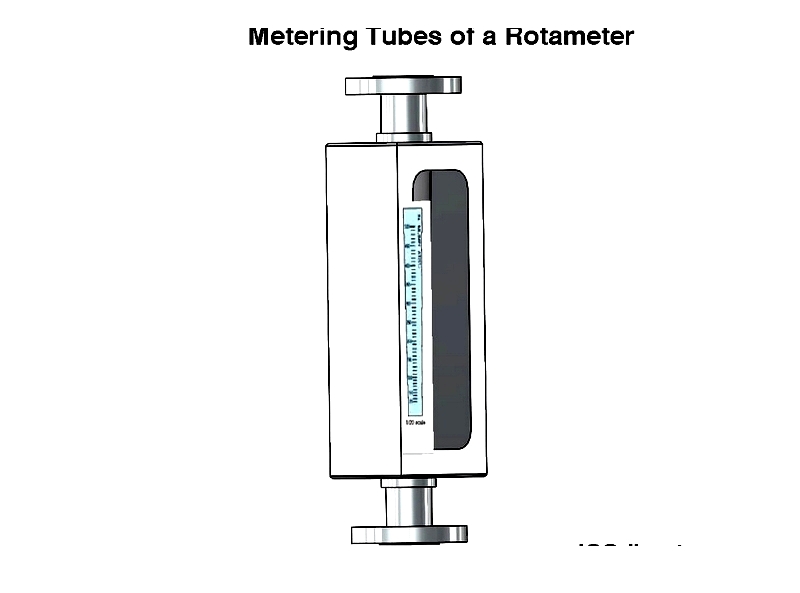

Metering Tubes

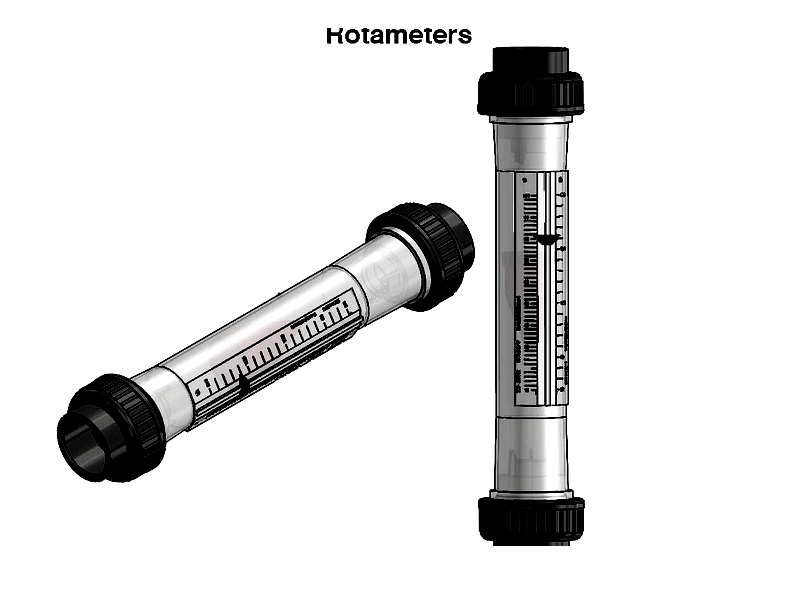

Tubes are crafted via mandrel and annealing for uniformity and strength. Glass tubes suit inclined readings, metals handle opaque fluids, and cost-effective plastics offer resilience.

Floats

Typically stainless steel, floats are selected based on meter capacity. Sharp-edged designs better accommodate viscosity changes, while spherical floats suit minor flow systems.

Features

Integrated alarms and controllers aid monitoring and calibration. Programmable microprocessors adapt to varying material properties and output needs.

Recorders and totalizers provide comprehensive tracking, supporting medical and food industry sanitary requirements.

Precision

Lab models achieve 0.5% full-scale accuracy over limited ranges, while industrial versions maintain 1-2% accuracy across broader scopes. Dual floats enhance precision for low-viscosity fluids like jet fuel.

Mounting

Rotameters install vertically with the wide end up. Options include insertion, flanged, threaded, and clamped methods.

Insertion types align perpendicular to flow; others run parallel. NPT is standard for threaded models.

Handling

Handle glass rotameters carefully to prevent damage. Avoid zero-flow settings that may block air. Clean glass with alcohol swabs. If floats stick, gently flip the tube.

Chapter 2: A Comprehensive Guide to Rotameter Types and Selection

Rotameters are essential for precise flow measurement across industries. Understanding their types and applications helps professionals optimize fluid dynamics and industrial monitoring. This guide explores glass tube, armored purge, flanged armored, and metal tube rotameters—highlighting their features, performance, and ideal uses. Proper selection ensures accuracy, compliance, and reliability in any process environment.

Glass Tube Rotameters

These popular meters serve chemical processing, water treatment, labs, pharmaceuticals, and food production. Borosilicate glass offers durability and clarity, while stainless steel or plastic floats enable accurate readings on graduated scales.