Introduction

This section provides information about walk-in test chambers, their applications, and manufacturers.

You will learn about:

- The definition of Walk-in Test Chambers

- Different types of Walk-in Test Chambers

- Manufacturing processes of Walk-in Test Chambers

- Standards for Walk-in Test Chambers

- Common tests conducted in Walk-in Test Chambers

- Additional relevant information

Chapter 1: What is a Walk-in Test Chamber?

Walk-in test chambers are specialized enclosures designed to simulate specific environmental conditions, including temperature, moisture, humidity, and other critical factors. These chambers play a vital role in evaluating product quality, durability, and lifespan. Their effectiveness stems from airtight interiors that can precisely recreate climatic conditions affecting product performance. They are particularly useful for stability testing, shelf life assessment, and aging studies.

Unlike smaller reach-in or benchtop chambers, walk-in test chambers offer sufficient space for personnel and large products. Their flexible workspace configurations adapt to diverse testing requirements. Most walk-in chambers are custom-built to meet client specifications, with options for various dimensions and internal bench configurations.

The spacious design of walk-in test chambers enables multiple testing applications, including stability studies, accelerated aging tests, shelf life evaluations, and bacterial cultivation. Researchers can precisely control environmental parameters like temperature, humidity, and vibration to simulate real-world product conditions. These chambers primarily serve to assess product reliability and durability by replicating actual usage environments.

Chapter 2: Types of Walk-in Test Chambers

Walk-in test chambers are available in numerous sizes and models to accommodate various testing requirements. Their spacious designs accommodate products of all sizes and batch quantities. These chambers can combine multiple test conditions to match specific product performance criteria. Customization options include access ports, reinforced floors, varied wall thicknesses, noise reduction features, different door and window styles, and safety enhancements.

Essentially, a walk-in test chamber is an insulated enclosure configurable for specific environmental simulations. Assembly typically involves interlocking foam panels or sealed welded panels, with some models large enough for vehicle testing.

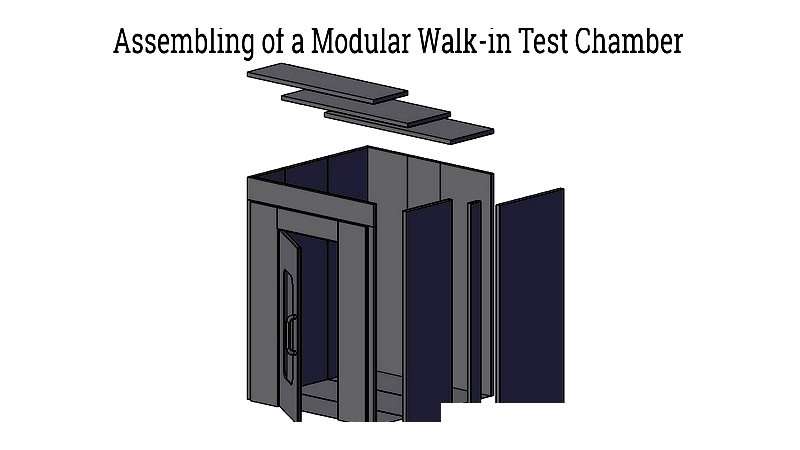

Modular Walk-in Test Chambers

Modular walk-in test chambers feature prefabricated, easily configurable designs. Their quick assembly meets diverse testing needs while maintaining standard chamber features like refrigeration, air circulation, and electrical systems. The primary advantage of modular chambers is their simple installation process that minimizes workplace disruption.

Available in sizes ranging from small single-person units to large-scale models, modular chambers are ideal for space-constrained areas or budget-conscious projects. Their panel construction typically consists of metal-skinned insulation cores with cam-lock connections, with panel dimensions scaling according to chamber size.

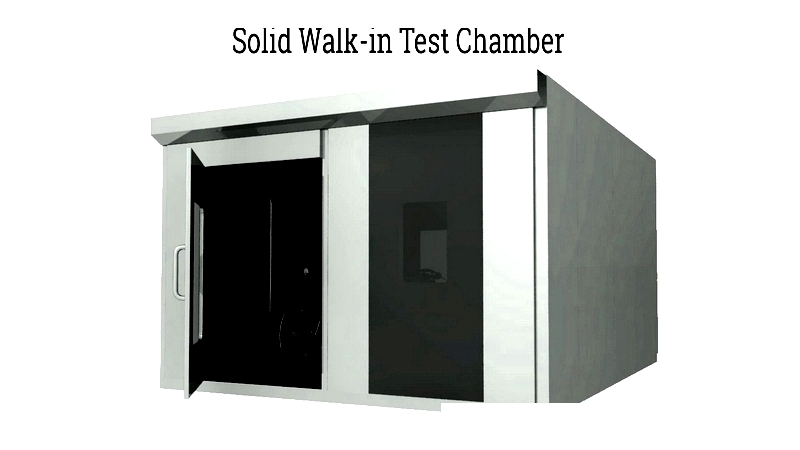

Solid Walk-in Test Chambers

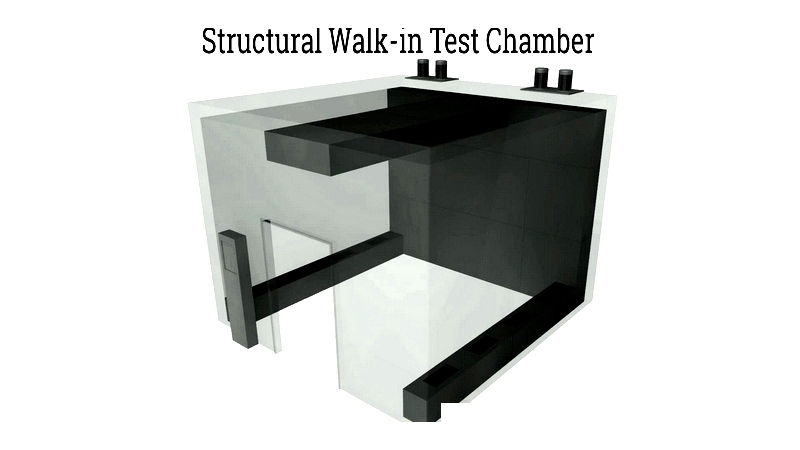

Solid walk-in test chambers are single-unit welded constructions capable of withstanding extreme conditions including high temperatures, rapid thermal changes, and high humidity. Unlike modular versions, these chambers feature hermetic seals around steel frames, sometimes assembled in sections for installation flexibility.

Their robust design supports testing of heavy, oversized products under high-pressure humidity conditions. The structural integrity of solid chambers comes from their tight seals and angle iron frames, which also facilitate loading through large doors and maximize floor space.

Both chamber types are available in various sizes, with selection based on specific testing needs. Custom designs are common for specialized applications, requiring close collaboration between manufacturers and clients during selection. The critical nature of test data demands careful chamber planning and engineering.

Chapter 3: Tests Performed in Walk-in Test Chambers

Product development requires thorough evaluation of lifecycle, endurance, strength, and resilience. While real-world testing is possible, it often proves time-consuming, costly, and unreliable. Walk-in test chambers provide controlled, adjustable environments that accurately simulate various conditions, offering crucial product quality and lifespan data.

These chambers enable engineers to recreate potential product environments, helping companies adapt products for global markets and assess component stability. Despite initial costs, the valuable data they provide helps prevent costly product failures.

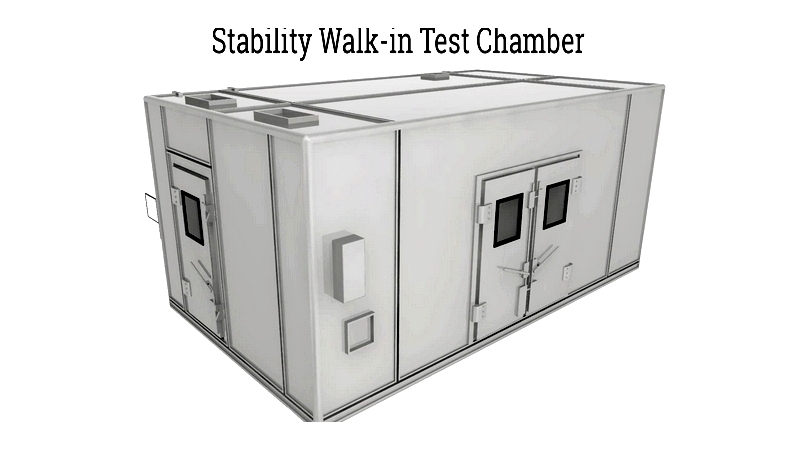

Stability Walk-in Test Chambers

Stability chambers maintain consistent temperature and humidity levels for extended periods, using combined heating, cooling, and water systems. Humidity chambers generate steam, while temperature-only models omit this feature. Achieving target conditions may require time, depending on chamber quality.

once established, conditions are maintained to evaluate product performance. Cold testing employs air circulation systems, with chamber sealing being critical for both test types.

These chambers help manufacturers develop durable, long-lasting products by determining lifespan and shelf life through stability testing.

Features of Stability Walk-in Test Chambers

- Temperature Reliability – Effective chambers maintain ±0.5°C variation across a -20°C to 94°C (-4°F to 201°F) range.

- Humidity Range – Standard chambers offer 20% to 95% RH, with specialty models reaching 98% RH. Desiccant dryers can extend lower limits to 5% RH.

- Cooling System – Most chambers feature durable, self-contained mechanical refrigeration systems.

- Remote Monitoring – Modern chambers often include remote monitoring capabilities for convenient test supervision.

Thermal Shock Walk-in Test Chambers

While similar to stability chambers in testing temperature effects, thermal shock chambers rapidly alternate between extreme temperatures. This tests product responses to thermal expansion and contraction, providing reliability data under severe temperature variations.

Altitude Walk-in Test Chambers

These combined temperature/altitude chambers simulate conditions up to 100,000 feet, crucial for aerospace component testing. They recreate low-pressure environments with temperature ranges from -75°C to 150°C (-103°F to 302°F), including rapid decompression capabilities meeting military standards.

Sand Dust Proof Walk-in Test Chambers

These chambers test product resistance to particulate environments, generating controlled dust suspensions. Air circulation systems ensure uniform particle size distribution, simulating sandstorm conditions. Typical capacities range from 1500L to 2000L (396-528 gallons), with certifications from IEC, ISO, and military standards.

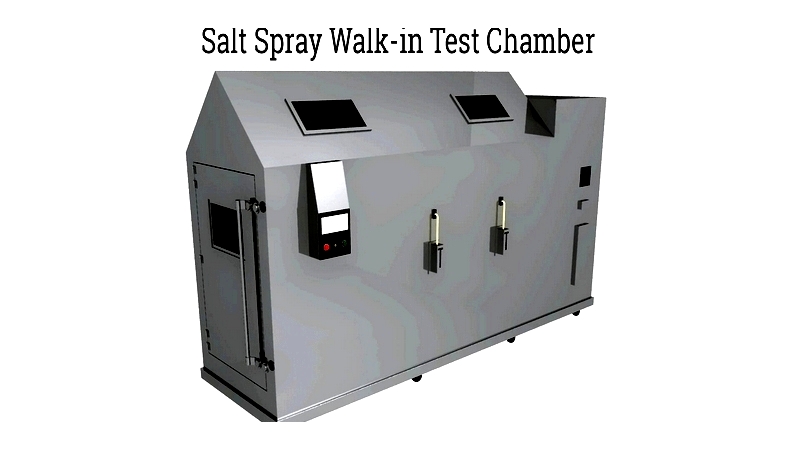

Salt Spray Walk-in Test Chambers

Specialized for corrosion testing, these chambers accelerate salt-contaminated environment effects on metals. They provide cyclic exposure to various conditions, evaluating coating effectiveness and material resistance.