Introduction

This article provides a comprehensive overview of different bolt types.

Continue reading to explore topics including:

- Components of Bolts and Bolted Joints

- Bolt-related Fastener Terminology

- Various Bolt Types

- And more...

Chapter 1: Understanding Bolt and Bolted Joint Components

Bolts are crucial fastening elements designed to secure assembly sections. They feature threads and typically pair with nuts. By passing through aligned, unthreaded holes and securing with nuts, bolts create reliable connections.

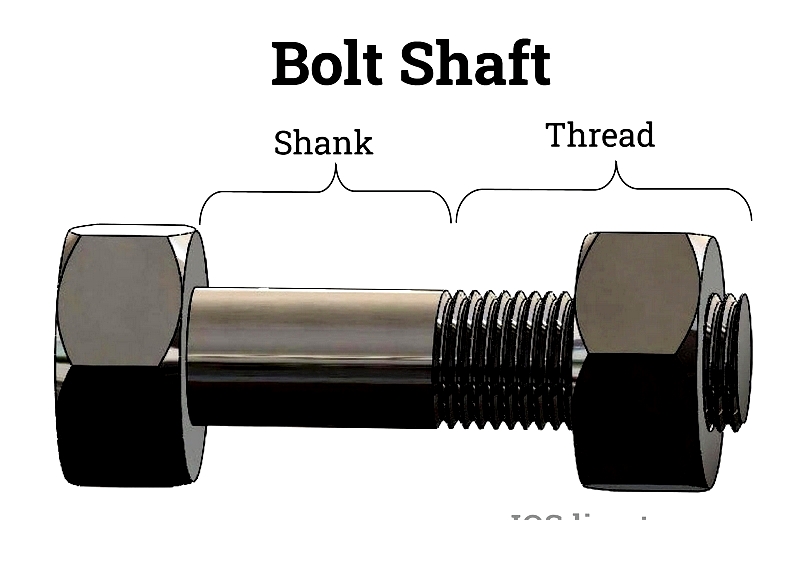

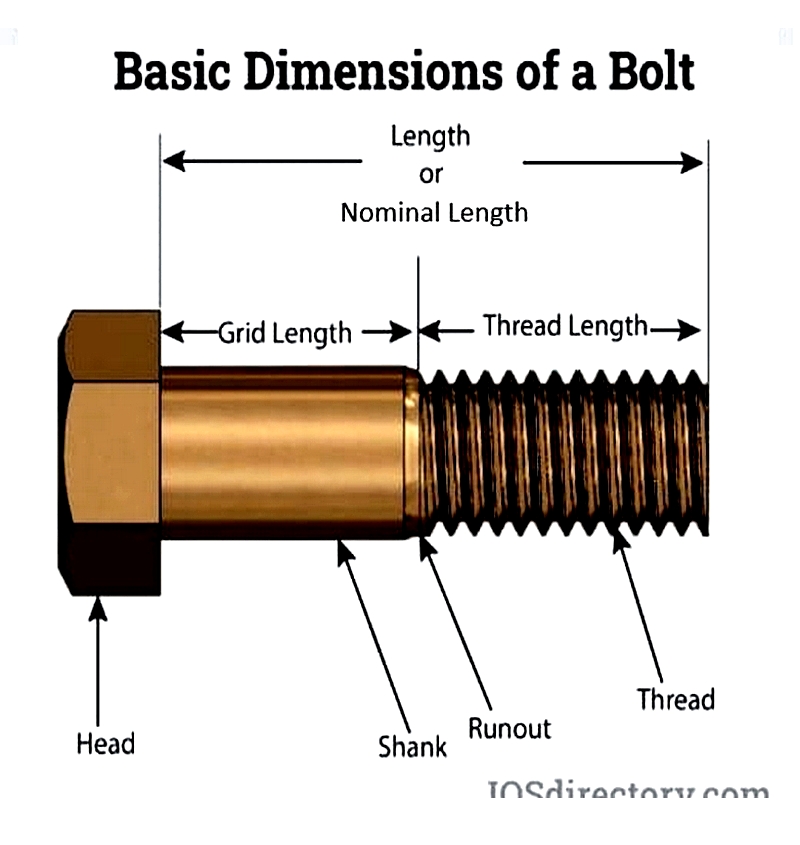

Bolt Shaft

The bolt shaft is a cylindrical component that withstands shear forces and prevents lateral movement. It consists of two primary sections:

- The shank (body) is the unthreaded portion beneath the head. Its length extends from the head to the threaded section. The shank ensures smooth contact within bolt holes and better stress distribution than threaded areas, making it essential to extend beyond fastened material interfaces.

Vibrations in assemblies may loosen bolts. Fully threaded bolts without shanks are particularly vulnerable to vibration-induced loosening.

- The threaded section features spiral ridges that engage with nuts, enabling pushing/pulling motions. Threads create secure joints when mated with nuts. While partial threading is sufficient, many bolts feature full-length threads.

Bolt Head

Bolt heads withstand axial fastening forces and accommodate wrench/driver torque. Common head types include:

- Hex heads: Six-sided design compatible with various wrenches.

- Countersunk heads: Conical shape with flat tops, often featuring drive slots for screwdrivers or hex tools.

- Dome heads: Rounded profile offering aesthetic appeal but limited tool grip.

Bolts are typically used with these components:

Nuts

Nuts serve as female counterparts in bolted joints, providing clamping force through threaded engagement. The resulting friction prevents loosening, with additional security from lock washers, jam nuts, pins, or thread-locking compounds.

Washers

These thin discs with central holes distribute fastener loads, preventing material deformation. Soft-material washers (plastic/rubber/urethane) absorb vibrations, while specialized versions create waterproof seals.

Chapter 2: Essential Bolt Terminology

Understanding bolt terminology is vital for engineers and professionals selecting mechanical fasteners. Below are key terms and interpretation guidelines for metric/imperial systems.

Shank Diameter

The unthreaded shaft diameter, also called nominal diameter, determines strength and fit in precision applications.

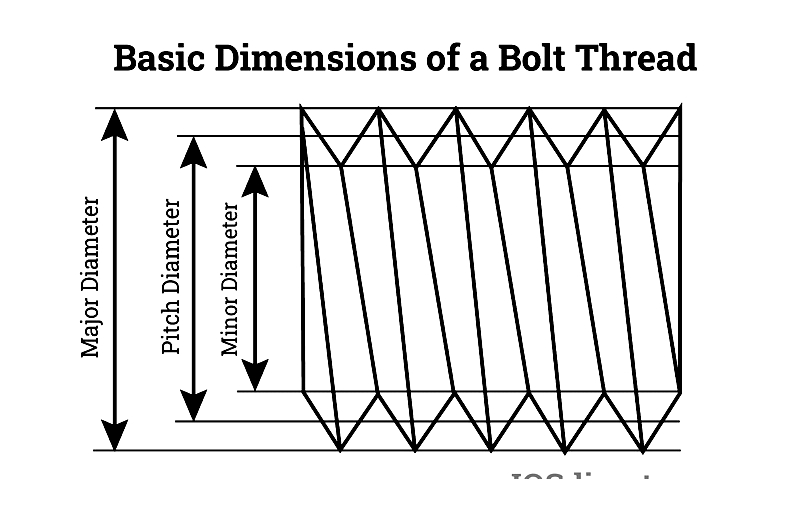

Major Diameter

Largest thread diameter (crest-to-crest), often matching nominal diameter, ensuring nut/hole compatibility.

Minor Diameter

Smallest thread diameter (root-to-root), influencing shear strength in fastener design.

Pitch Diameter

Midpoint between major/minor diameters, critical for threading compatibility.

Fundamental thread dimensions:

Nominal Length

Total shaft length comprising grip (unthreaded) and thread lengths, crucial for proper clamping.

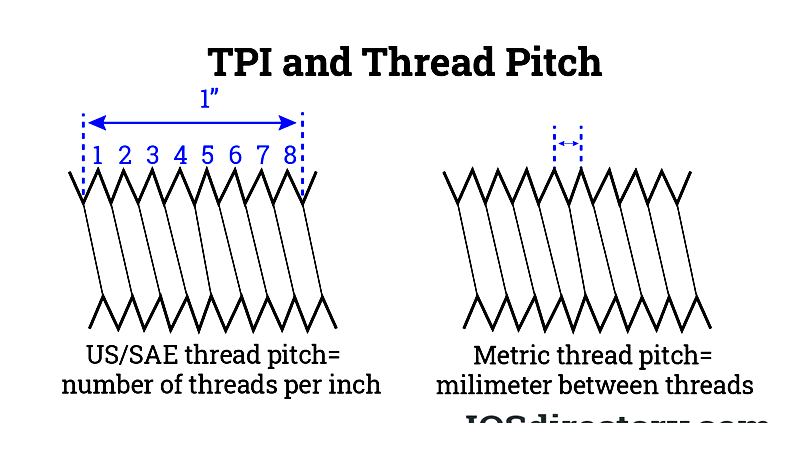

Thread Pitch

Axial distance between thread crests (mm in metric systems), affecting tensile strength and vibration resistance.

Metric bolts follow ISO/DIN standards. For example, M10-1.0x20 indicates:

- M: Metric system

- 10: 10mm diameter

- 1.0: Fine thread pitch

- 20: 20mm length

Unspecified pitch (e.g., M12-50) indicates coarse threads. Selection depends on application requirements.

Threads Per Inch (TPI)

Imperial measurement of threads per inch. Example: ¼"-20x2" means:

- ¼": Diameter

- 20: TPI

- 2": Length

TPI knowledge prevents cross-threading and ensures proper load capacity.

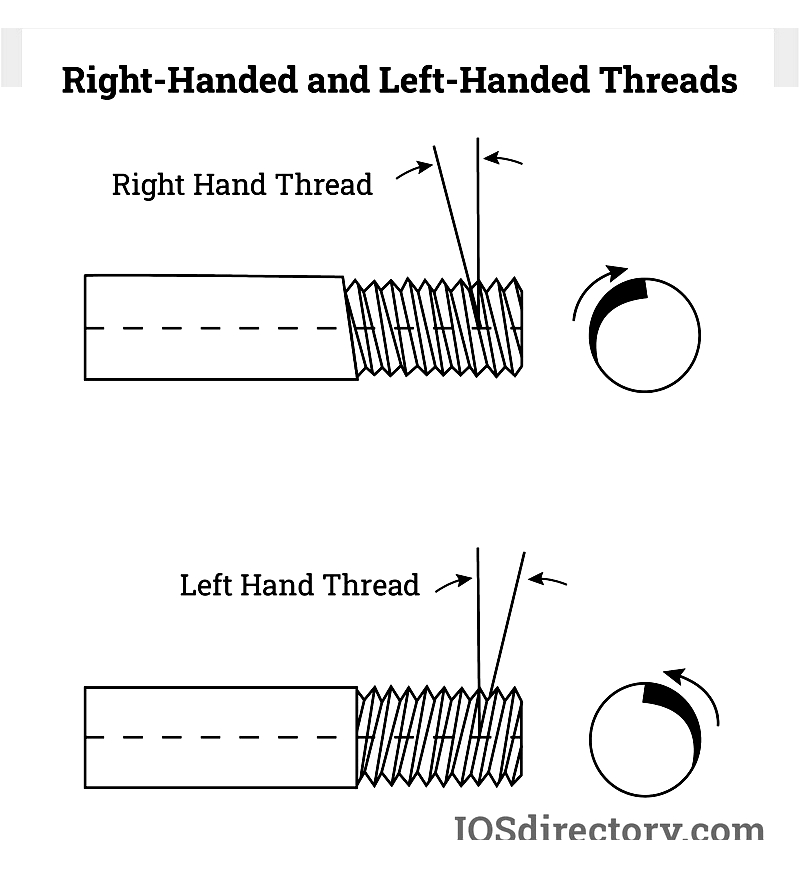

Thread Direction

Right-handed (clockwise-tightening) threads are standard, while left-handed (counterclockwise) versions prevent loosening in rotational applications like pedals or saw blades.

Chamfer

Beveled thread ends easing nut insertion, with angles measured from bolt axis.

Additional Terminology

- Head Style: Determines required tools and assembly fit

- Thread Class: Specifies tolerance levels (e.g., 2A/2B)

- Grade: Indicates material strength (e.g., Grade 8, 10.9)

- Coating: Enhances corrosion resistance (zinc, galvanizing, etc.)

- Washer Types: Improve load distribution and security

Mastering these terms enables informed bolt selection and optimal joint performance. Always verify product certifications and standards compliance when sourcing fasteners.