Introduction

This article provides an in-depth exploration of urethane wheels.

It covers detailed information on various aspects including:

- Working Principles of Urethane Wheels

- Different Types of Urethane Wheels

- Applications and Advantages of Urethane Wheels

- And More...

Chapter 1: Fundamental Principles of Urethane Wheel Design and Function

This chapter examines urethane wheels, focusing on their composition, structure, and operational principles.

What are Urethane Wheels?

Made from molded urethane (polyurethane), these wheels feature elastomeric properties due to urethane carbamate linkages, derived from "elastic polymers."

Urethane wheels combine the benefits of metal, plastic, and rubber wheels. They offer better cost-efficiency, flexibility, noise reduction, durability, and improved resistance to impacts, abrasion, and corrosion compared to metal wheels.

Urethane outperforms plastic in low-temperature conditions, impact resistance, abrasion resistance, and radiation resistance. Compared to plastic wheels, urethane wheels provide superior noise reduction, resilience, elastic memory, and cost advantages. With a wide hardness range, customization ease, and excellent impact resistance, urethane surpasses rubber. Additionally, urethane wheels can be retooled and recoated, reducing costly adjustments.

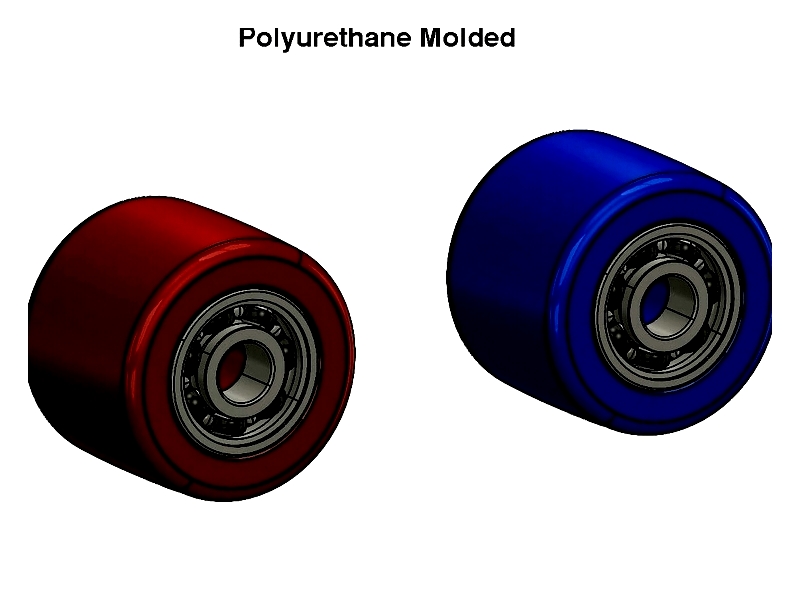

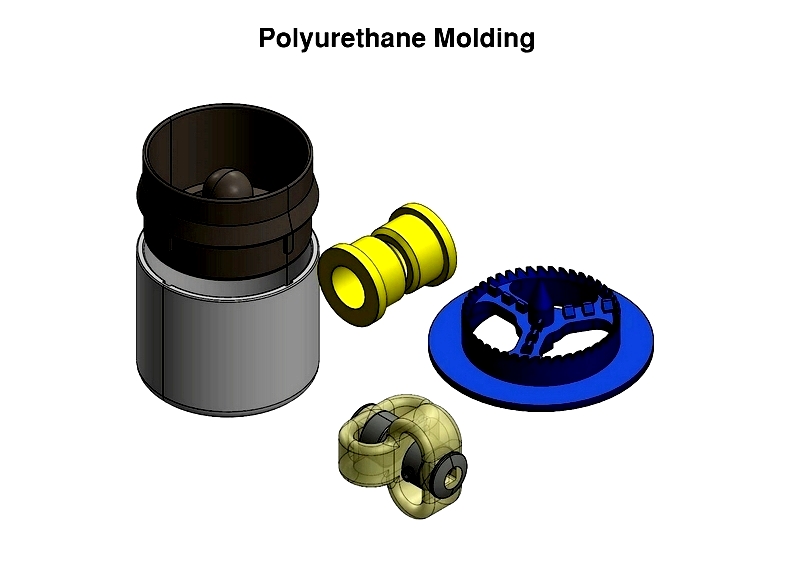

Polyurethane Molding

Urethane wheels are manufactured through polyurethane molding, where a urethane polymer system cures within a mold to create plastic components. Polyurethane's excellent processability makes it ideal for producing various consumer and industrial products. This method achieves precise tolerances and complex shapes, including those needed for urethane wheels.

Polyurethanes can be formulated to exhibit diverse mechanical properties, from soft and flexible to hard and strong, with some formulations yielding high-performance engineering-grade results.

Urethane Wheel Construction

This section explores how urethane wheels are built.

Urethane Fabrication Methods

Urethane wheels are fabricated using standardized components through two primary techniques.

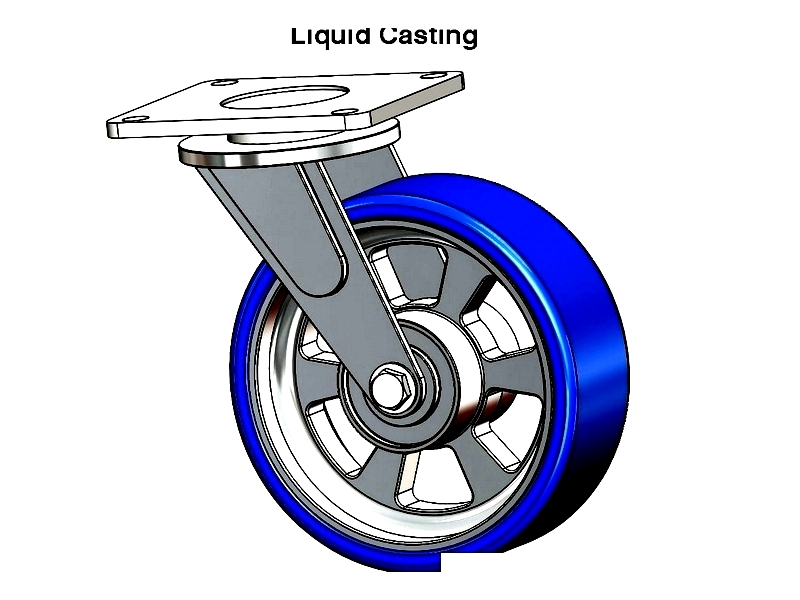

Liquid Casting

Urethane is liquefied by heating and poured into wheel-shaped molds, where it cools and solidifies. Synthetic resins may be added during this process, mainly used for prototyping and small-scale production.

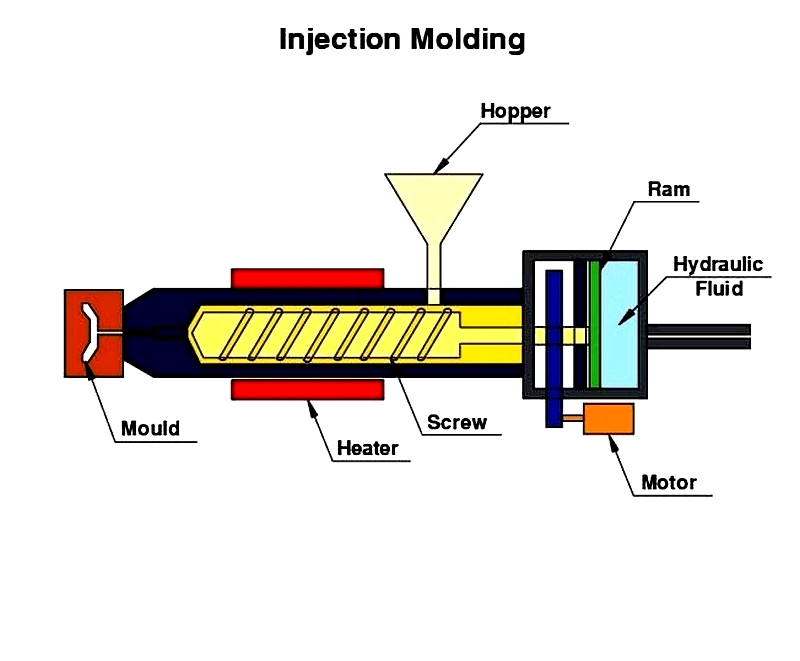

Injection Molding

This method involves melting urethane and injecting it into molds using low-pressure pneumatic guns. Injection molding systems require significant energy due to multiple motors and heaters. Research focuses on improving energy efficiency. Accounting for 32% of plastic processing, injection molding remains widely used.

Alternative Fabrication Methods

Urethane wheels can also be made from solid urethane or composite materials like cast iron, aluminum, and steel, suitable for heavy-duty applications. Bonded-to-metal wheels have metal cores with urethane treads. Their manufacturing is cost-effective, and they're FDA-approved for clean rooms.

Urethane Materials

Polyurethane is a type of urethane polymer with no significant difference between the two. Polyurethanes mainly consist of polyols and diisocyanates, supplemented by curatives and additives for enhanced properties. Foams require blowing agents, surfactants, and catalysts for structure development.

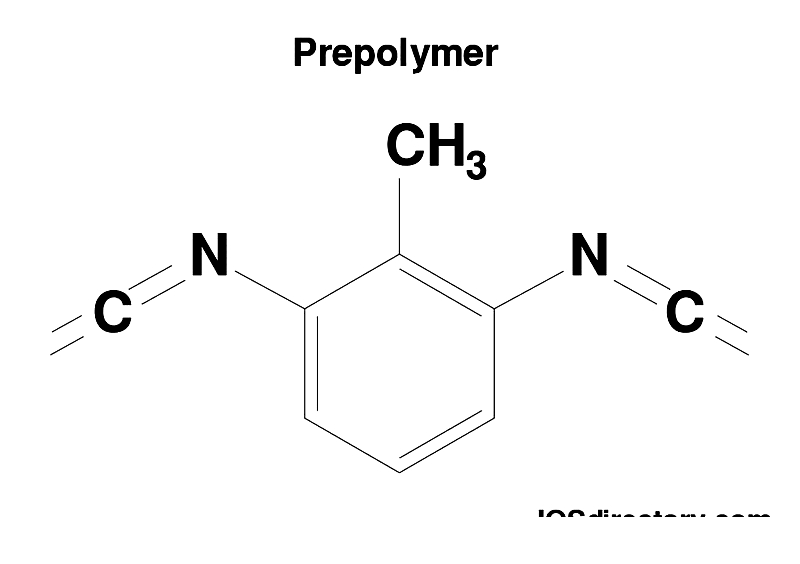

Prepolymer System

Polyurethanes include polyols, diisocyanates, and additives for property enhancement. Blowing agents, surfactants, and catalysts help create foam structures.

Polyol in Urethane Wheels

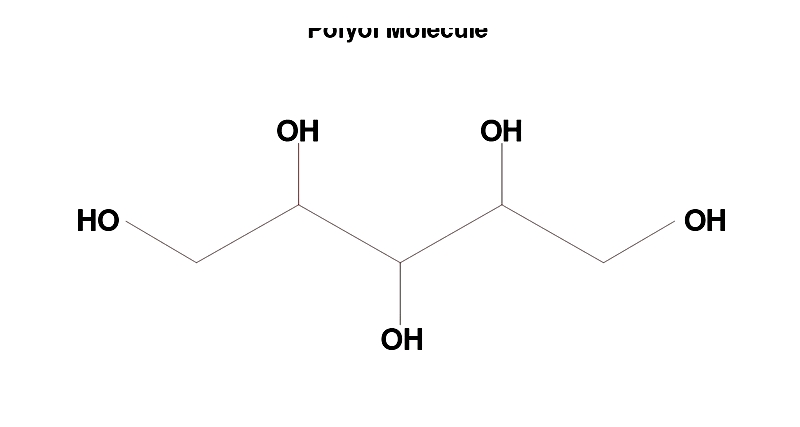

Polyol is an organic molecule with hydroxyl (OH) groups. In urethane casting, polyols are categorized as polyether or polyester polyols.

Polyether Material

Produced from organic oxides and glycol, polyether polyols offer excellent impact resistance, low heat buildup, hydrolysis resistance, and low-temperature performance. PTMEG and PPG are common, with PTMEG being superior but more expensive.

Polyester Urethane Material

Formed through di-acid and glycol polycondensation, polyester polyols provide better abrasion, oil, heat aging, shock, solvent, and tear resistance than polyether polyols.

Specialty Polyols

Polycarbonate and polycaprolactone are common polyester polyols. Polycarbonates offer strength and rigidity, while polycaprolactone enhances resistance to water, oil, solvent, and chlorine.

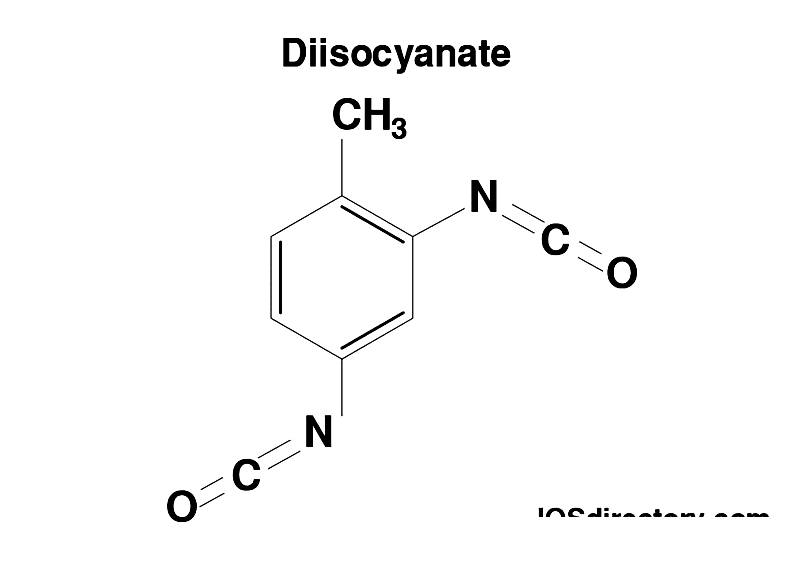

Diisocyanate Compounds

Diisocyanates, like polyols, are fundamental polyurethane components. They are classified as aliphatic or aromatic.

Aliphatic Diisocyanates

These non-yellowing compounds are less reactive, making them suitable for chemical-resistant coatings. Common types include HMDI, HDI, and IPDI.

Aromatic Diisocyanates

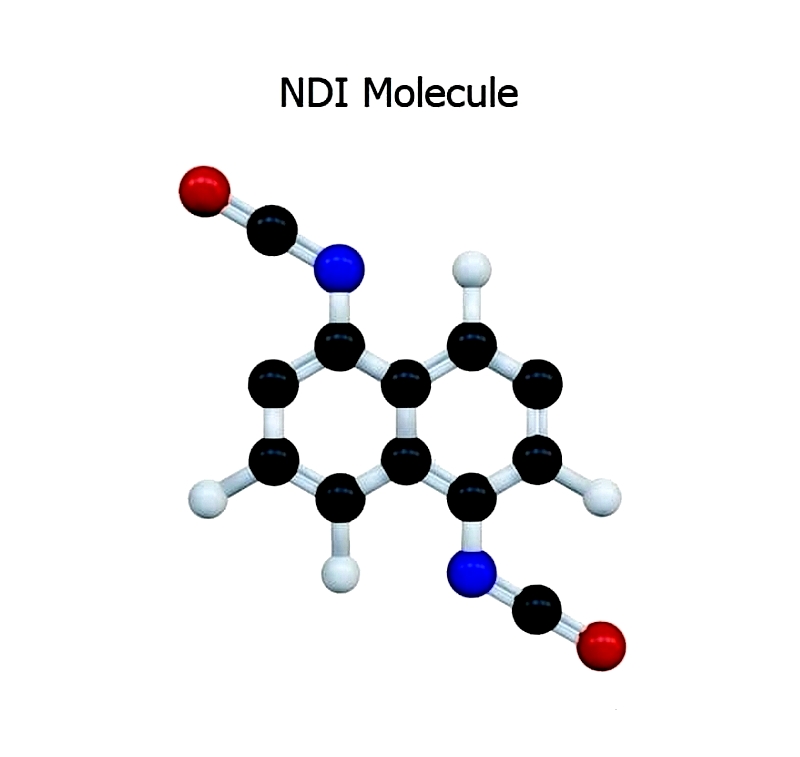

Accounting for over 90% of diisocyanate use, these include TDI, NDI, and MDI.

Polyurethane Foam Components

Foams require blowing agents, surfactants, and optional catalysts to create cellular structures. These elements regulate gas formation for optimal foam development.

Blowing Agents

These introduce gas into the polymer system to form foam. Originally, CFC-11 was used but was banned due to ozone depletion. Alternatives include water, pentane, and hydrocarbons.

Surfactant Additives

Silicone-based surfactants reduce surface tension, stabilize foam, control cell size, and prevent shrinkage.

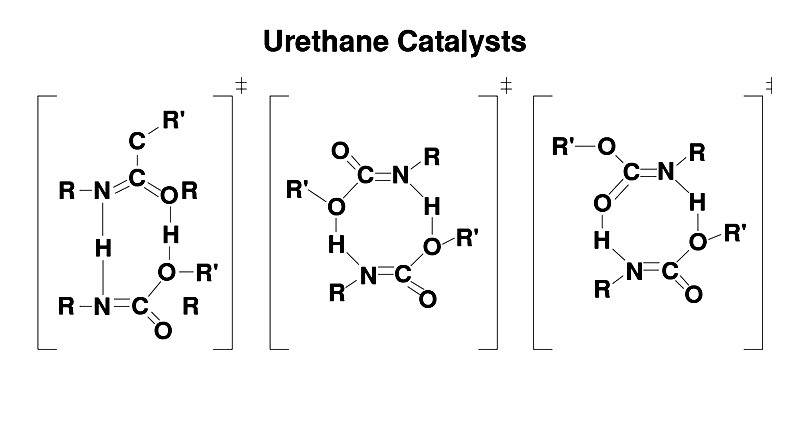

Urethane Catalysts

Catalysts regulate reaction rates between isocyanate and hydroxyl groups, ensuring balanced foam formation. Imbalanced rates can cause shrinkage or premature expansion.

Curative and Chain Extenders

These crosslink molecules in the polyol-diisocyanate reaction, producing solid or semi-solid elastomers. Common types include hydroxyls and amines.

Hydroxyls (Diols)

These terminal hydroxyl molecules link prepolymers. 1,4-butanediol (BDO) is commonly used with MDI prepolymers.

Amines

Amine groups can also attach to prepolymers. MOCA is used with TDI prepolymers but is carcinogenic, leading to alternatives like 4,4-methylenebis(