Introduction

This article provides an in-depth examination of PVC Ball Valves.

You will explore various topics including:

- What is a PVC Ball Valve?

- Types of PVC Ball Valves

- PVC Ball Valve Structure

- Benefits of PVC Ball Valves

- And more...

Chapter One – What is a Ball Valve?

A PVC (polyvinyl chloride) ball valve is a plastic valve designed to start and stop fluid flow, featuring a rotary ball with a bore. A quarter-turn rotation of this ball effectively stops fluid movement. These valves are highly durable, cost-effective, and suitable for controlling various substances such as water, air, corrosive chemicals, acids, and bases. PVC ball valves exhibit excellent resistance to low temperatures and pressure while maintaining relatively lower mechanical strength. Like all ball valves, they operate by rotating the ball 90° to stop flow.

The operation of PVC ball valves depends on a central rotating component called the rotary ball. A stem on top of the ball allows for manual or automated adjustment, depending on the valve's design. When the valve handle aligns with the pipeline, the valve remains open; when perpendicular, the flow stops.

Made from non-flammable plastic, PVC ball valves can withstand temperatures from -14°C to 140°C. They perform comparably to traditional ball valves, offering a lightweight structure, compact design, easy installation, and adaptability for various applications.

Chapter Two – What are the different types of PVC ball valves?

PVC ball valves come in various types, each designed for specific industrial, commercial, or residential fluid control and pipeline management applications. These valves are categorized based on key factors such as port count, seat types, body construction, ball accessibility, and bore size. Choosing the right PVC ball valve depends on your piping system's unique requirements, including operating pressure, pipe diameter, fluid temperature, connection ports, end connectors, flow direction, and system configuration.

PVC (polyvinyl chloride) ball valves are made from vinyl resin, a thermoplastic known for its versatility and chemical resistance in plumbing and fluid handling systems. Like other high-performance thermoplastics, PVC is an eco-friendly, cost-effective material that can be melted and reshaped multiple times, offering sustainable manufacturing benefits. Beyond PVC ball valve production, PVC is widely used in piping and fittings due to its corrosion resistance, high strength-to-weight ratio, and long service life.

PVC Ball Valve Types

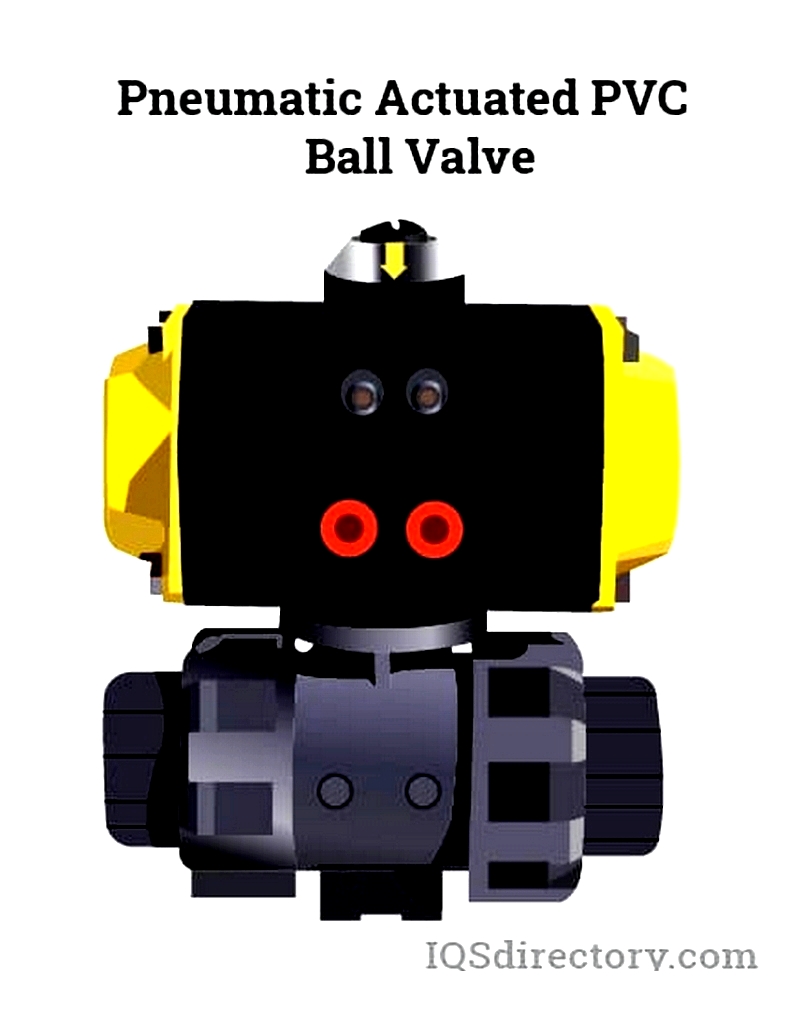

Automatic Valves

Automatic PVC ball valves come in two-way and three-way configurations. These valves use pneumatic or electric actuators, making them ideal for automated process control in water treatment, chemical dosing, irrigation, and industrial fluid transfer. They enable remote control and integration into automation systems, providing precise flow regulation, improved efficiency, and reduced manual operation. Their robust design supports various media, including potable water, compressed air, corrosive chemicals, gas, and oil.

Check Valves

PVC ball check valves prevent backflow, a critical function in filtration, wastewater management, and pump systems. They automatically release excess pressure and stop reverse flow, protecting equipment and maintaining system integrity. Trunnion-mounted check valves are common in demanding environments like chemical processing, water supply, and refrigeration systems. Unlike manual PVC ball valves, check valves have a simple, stemless design for low-maintenance operation.

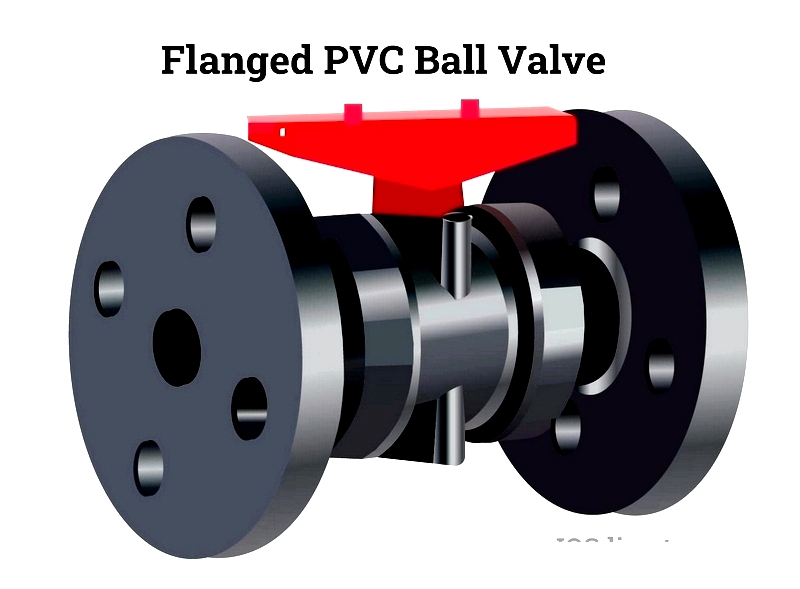

Flanged PVC Ball Valve

Flanged PVC ball valves feature flange-based connections for easy installation, leak-proof joints, and quick maintenance in industrial piping systems. These full bore valves, available with two to four ports, are designed for high flow rates and minimal pressure loss. Their robust flanges suit various operating pressures. Flanged ball valves are typically joined with bonding agents, gaskets, or bolts, making them ideal for water distribution, wastewater systems, and chemical transfer lines.

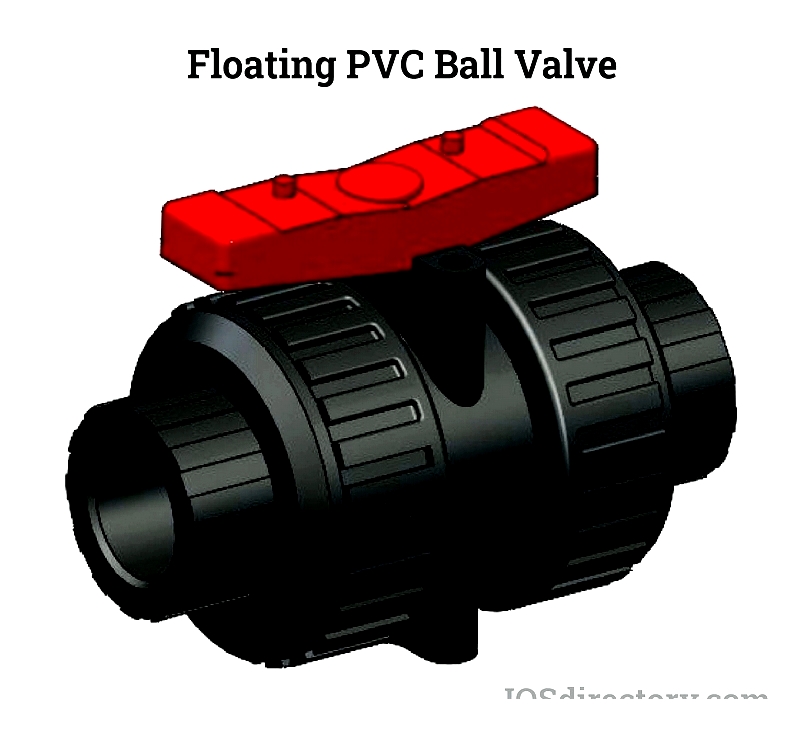

Floating PVC Ball Valve

In floating PVC ball valves, the ball is suspended in the flow stream and held by precision seats. This design ensures a tight seal as the ball shifts slightly under pressure, pressing against the downstream seat. The shaft allows quick 90° actuation, making these valves ideal for on/off applications in plumbing, irrigation, and low-to-moderate pressure industrial systems.

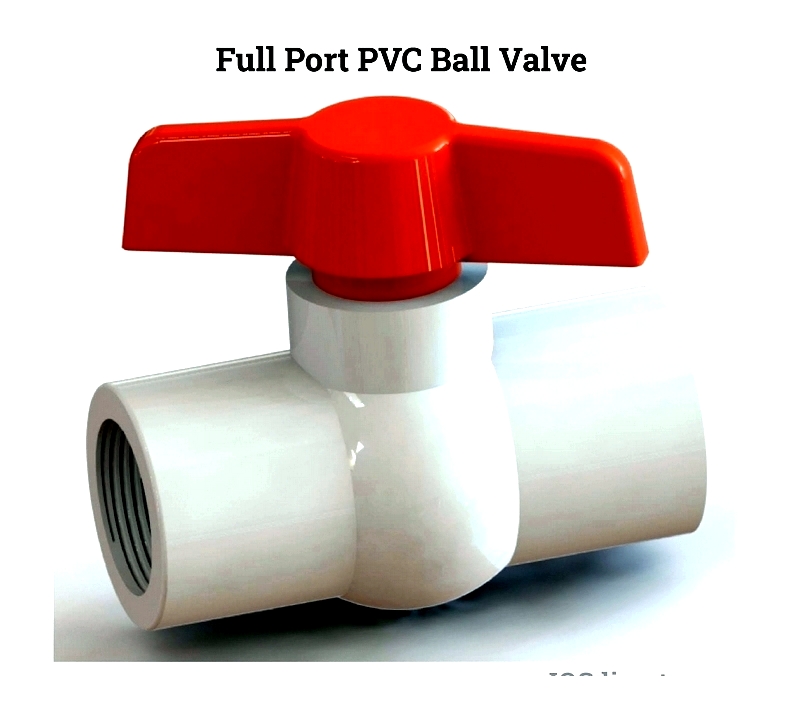

Full Port PVC Ball Valve

Full port PVC ball valves have a ball opening matching the pipeline's inner diameter. This design maximizes flow capacity, reduces turbulence, and prevents clogging, making them ideal for bulk fluid transfer and potable water systems. They are recommended for slurry, viscous media, and chemical handling.

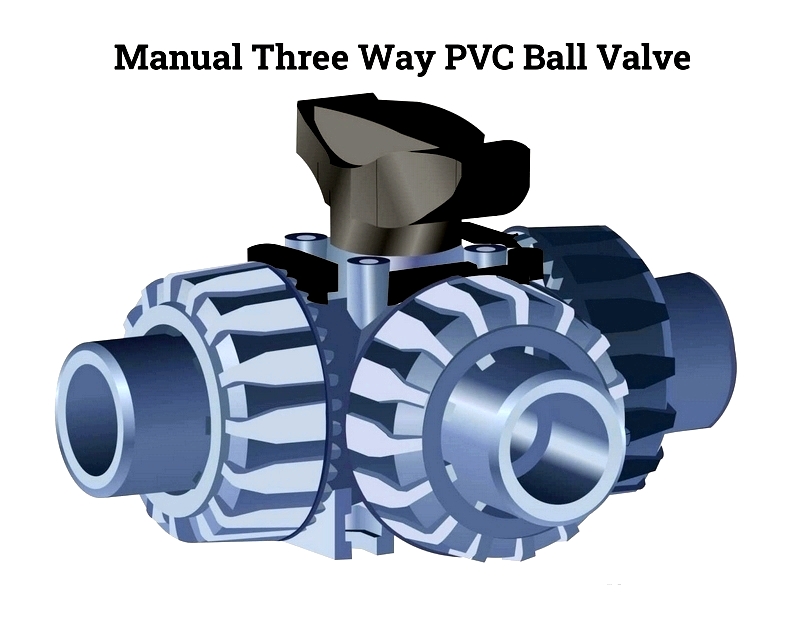

Manual Operated Valves

Manual PVC ball valves offer a simple, cost-effective solution for basic flow control. The most common is the two-way valve, operated by a 90° handle turn. These valves are suitable for residential plumbing, aquariums, and small-scale industrial systems requiring occasional shutoff.

Three-way manual valves come in T-port and L-port configurations for flow mixing or diversion. A quarter-turn handle allows easy media redirection between pipelines.

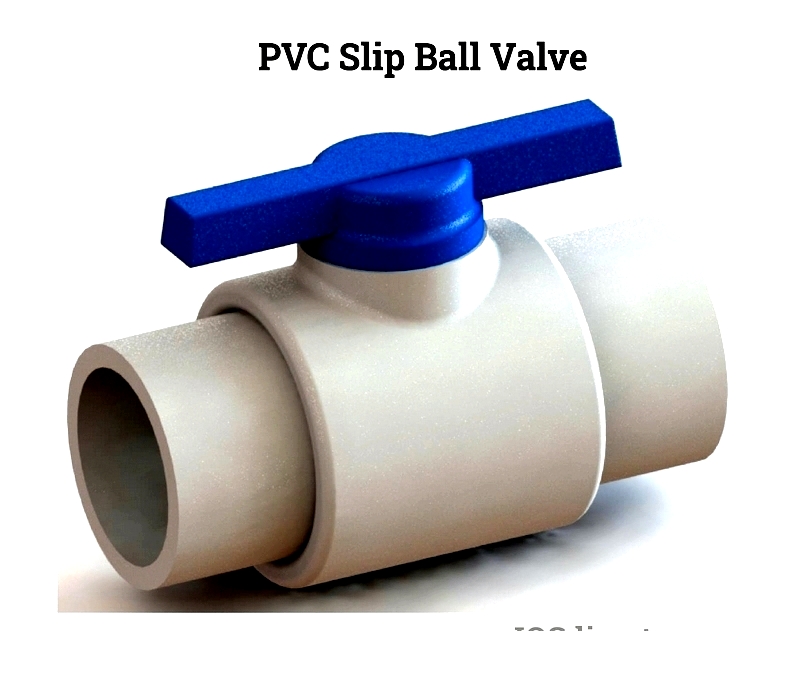

Slip PVC Ball Valve

Slip PVC ball valves feature solvent weld slip fittings for quick, leak-proof installation in pipes up to two inches. Commonly used in plumbing and irrigation systems, these valves are attached with primer and solvent cement for a secure joint.

Standard Port Valve

Standard port PVC ball valves have a slightly reduced bore, resulting in some pressure drop and lower flow velocity. They are cost-effective choices for general utility piping and non-critical water systems.

Threaded PVC Ball Valves

Threaded PVC ball valves have internal or external threads for easy, reusable connections. They are versatile and compatible with Schedule 40 and 80 PVC pipes, suitable for residential, commercial, and industrial applications.

Three Way PVC Ball Valve

Three-way PVC ball valves offer L-port or T-port configurations for flow diversion or mixing between three pathways. They are valuable in process piping and chemical batching, allowing flexible flow control with a simple quarter-turn.