Introduction

This section provides an overview of metal stamping technologies and lists leading companies in the field.

You will learn about:

- metal Stamping fundamentals

- Different metal Stamping Methods

- metal Stamping Die technology

- metal Stamp Design principles

- And more advanced topics

Chapter 1: What is metal Stamping?

metal stamping involves compressing metal sheets to reshape them into precisely designed components. Computer-controlled presses apply compressive forces to transform flat metal sheets into complex shapes with exceptional accuracy.

The success of metal stamping depends on the duration of compressive force application, which is carefully monitored. After stamping, components undergo trimming and finishing to meet design specifications. Modern metal stamping relies on technology to control force, compression duration, and programmed parameters.

While metal stamping has historical roots, modern technology has significantly advanced the process. Computer numerical control (CNC) has revolutionized metal stamping, with CAD designs digitally tested before being converted into CNC codes.

metal stamping offers multiple advantages as a cold forming technique. It eliminates heating requirements, reduces costs, and can produce complex shapes difficult to achieve with other methods. Its precision makes it ideal for manufacturing intricate parts.

Chapter 2: The Internet of Things (IoT)

The Internet of Things (IoT) refers to interconnected devices with sensors, software, and network capabilities that collect and share data. These smart devices communicate through internet-enabled networks, creating autonomous systems.

IoT plays a crucial role in modern metal stamping by enabling real-time machine monitoring, performance tracking, and predictive maintenance. This proactive approach replaces traditional reactive problem-solving methods.

Benefits of Internet of Things (IoT)

IoT's primary benefit is predictive maintenance, reducing downtime and improving efficiency. Manufacturers increasingly adopt IoT for its profitability and operational advantages.

-

Real Time Machine Monitoring

IoT sensors analyze data to predict component failures, allowing preemptive replacement and minimizing downtime.

-

Machine Longevity

Preventive measures extend equipment lifespan by preventing failures and enabling scheduled maintenance.

-

Cost Reduction

IoT improves maintenance efficiency and resource utilization, significantly lowering operational costs.

-

Productivity Increase

Predictive maintenance maintains optimal machine performance, eliminating downtime and boosting productivity.

Challenges of IoT metal Stamping

While IoT offers predictive capabilities and real-time data, implementation requires sensor installation and staff training. These initial costs may deter some manufacturers from adoption.

Chapter 3: Types of metal Stamping Technologies

metal stamping technologies include servo-driven presses, high-speed stamping, hydraulic systems, and CNC stamping. Feeding mechanisms vary from automatic sheet/coil feeding to manual blank feeding, depending on material thickness.

Computer Numerical Control (CNC)

CNC metal stamping incorporates all standard processes but uses programmed G-codes and M-codes. This method offers high precision and accuracy for complex shapes, though at slower production speeds suitable for low-volume manufacturing.

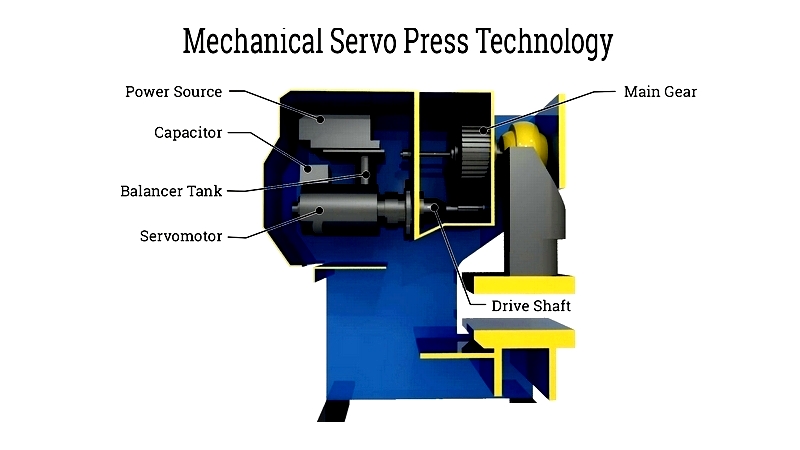

Mechanical Servo

Servo presses replace traditional motors with servo motors for greater flexibility and precision control. These systems adjust speed, dwell time, and stroke length to meet specific application requirements.

Mechanical servo presses outperform hydraulic systems in speed while maintaining precision. Despite higher costs, their efficiency makes them increasingly popular in manufacturing.

Selecting the appropriate stamping method depends on production volume, design complexity, and required accuracy. Manufacturers collaborate with clients to determine the optimal solution.

Hydraulic

Hydraulic systems use fluid pressure between cylinders to generate stamping force. Pressure regulation mechanisms ensure safe operation while maintaining sufficient force for metal forming.

Mechanical

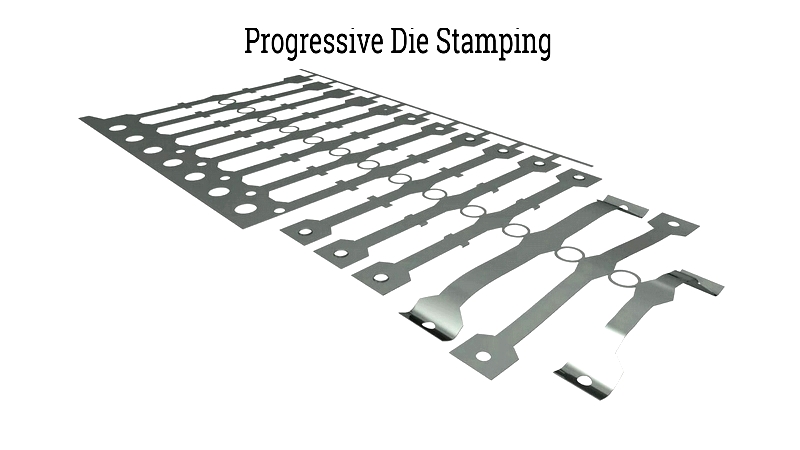

Traditional mechanical stamping remains effective for high-volume production of simple shapes. Various drive mechanisms control the stamping cycle, with single-geared presses being most common for progressive stamping applications.

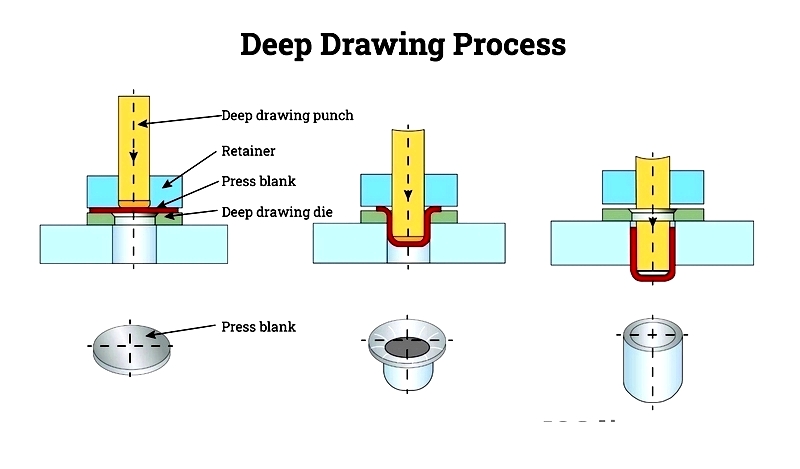

Chapter 4: Deep Drawn Stamping

Deep drawing stretches metal blanks around a plug into a die, producing hollow components with depth exceeding width. This process creates seamless cylindrical or box-shaped parts with high dimensional accuracy.

The drawing process carefully controls metal flow to prevent wrinkling or splitting. Multiple drawing operations may be needed for tall geometries, with each step precisely monitored.

The Deep Drawn Stamping Process

Successful deep drawing requires careful execution of key steps:

- Blank Preparation – Precise cutting of metal sheets to required dimensions.

- Die and Punch Design – Computer-designed tools ensure proper material flow and dimensional accuracy.

- Blank Lubrication – Essential for smooth material flow and preventing surface damage.

- Drawing – Controlled deformation of clamped blanks into die cavities.

- Finishing – Secondary processes to achieve final specifications and surface quality.

Applications for Deep Drawn Stamping

Deep drawn components serve multiple industries:

- Automotive - Fuel systems, powertrain components, and safety parts

- Electronics - Enclosures, connectors, and circuitry

- Medical - Surgical instruments and diagnostic equipment

- Consumer Goods - Appliances and cookware

Benefits of Deep Drawn Stamping

This century-old process offers significant advantages:

- Accuracy – Exceptional dimensional precision

- Surface Finish – Smooth surfaces from single deformation

- Cost Efficiency – Reduced waste and secondary processing

- Material Control – Improved mechanical properties through grain flow

- High Volume – Fast production of large quantities

Deep drawn parts exhibit superior strength from seamless construction, justifying initial equipment costs through production efficiencies.

Chapter 5: Basics of metal Stamping

metal stamping transforms flat sheets into specified shapes, serving industries from automotive to electronics through various techniques.

Punching

This process creates holes and features using punch tools and