Introduction

This section covers all the essential information about cordage available on the internet.

You will learn about:

- The definition of cordage

- Cordage production methods

- Different cordage products

- Practical applications of cordage

- Additional related information

Chapter 1: Understanding Cordage

Cordage consists of fibers, strands, or fabrics twisted or braided together to create stronger, more durable ropes. This combination produces a final product with greater strength than its individual components. Commonly called rope, cordage has served as an essential tool for sailors, farmers, and ranchers throughout history. Its remarkable strength and versatility make it invaluable for securing, fastening, and moving objects safely and efficiently.

Cordage design and manufacturing have seen significant improvements over time. While traditional materials like hemp and cotton were once standard, modern synthetic fibers such as nylon and polypropylene now dominate, offering better durability and performance.

Chapter 2: The Manufacturing Process of Cordage and Rope

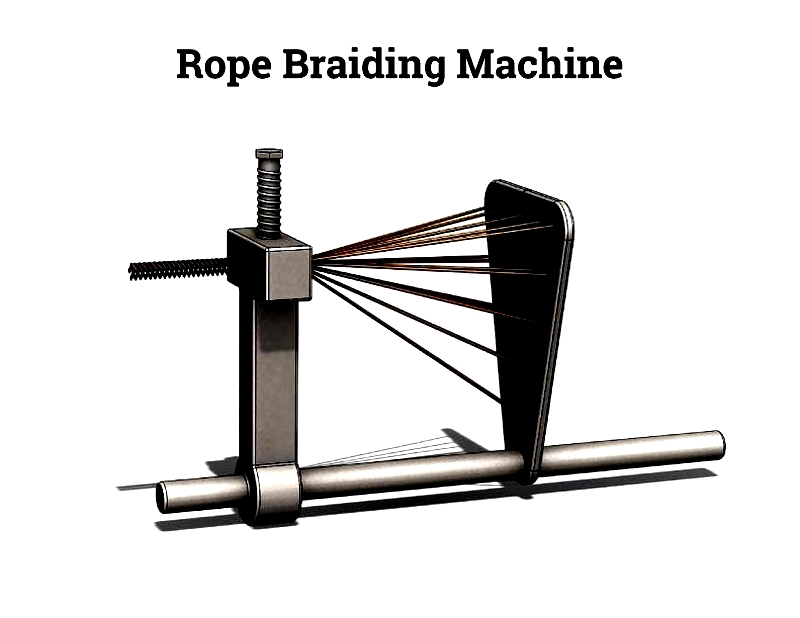

Rope production has advanced considerably from its traditional origins while preserving fundamental rope-making principles. Historically, artisans made rope manually by stretching material strands over long distances, anchoring one end, and twisting them together using a wheel—a method called "rope walking." This technique formed the basis for contemporary manufacturing processes.

Modern technology has transformed rope production into a highly automated process. Advanced machinery now handles braiding and twisting with greater precision, enabling mass production while maintaining consistent quality. These developments have increased efficiency and expanded rope applications across various industries.

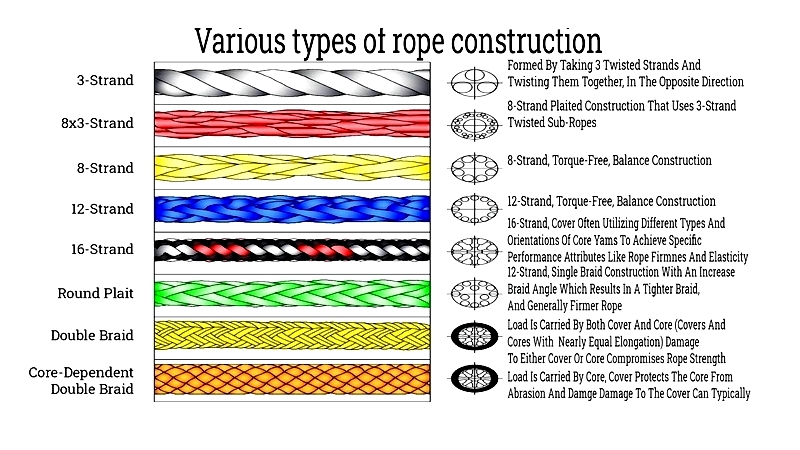

Rope manufacturing primarily involves two techniques—braiding and twisting. Though similar in appearance, braided and twisted ropes differ in structure, strength, and uses. Recognizing these distinctions helps in selecting the appropriate rope type for specific needs, whether for marine, climbing, or industrial purposes.

Braided Rope

Braided rope is created by weaving multiple yarns or strands—from eight to several hundred—into a flexible, unified structure. Preferred in fields like arboriculture, sailing, and rescue operations, braided rope offers strength, smoothness, minimal stretch, and resistance to kinking. Three main braiding methods exist:

- Hollow – Featuring a tubular braid with no core, this lightweight option suits watersports tow lines and utility cords.

- Solid – With an internal core, solid braided rope provides greater tensile strength for applications like flagpole lines and tie-downs.

- Double – Combining a braided core with an outer jacket, this type delivers maximum strength and abrasion resistance for marine and industrial uses.

Twisted Rope

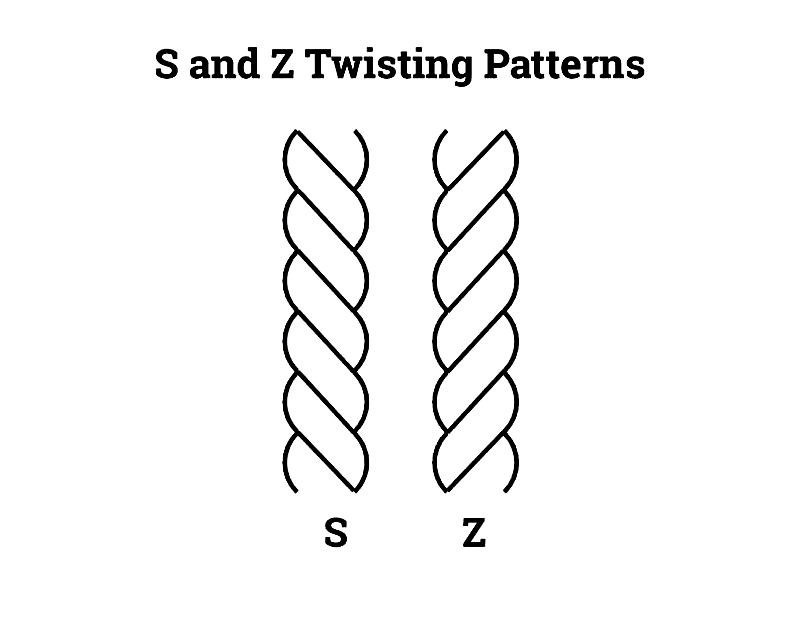

Twisted rope, or laid rope, is made by helically twisting fiber strands—typically three or four—around each other. Valued for its affordability and shock absorption, twisted rope is commonly used in construction, agriculture, and general tying applications.

Step-by-Step Manufacturing Process

Rope production starts with selecting either natural or synthetic fibers, each offering unique benefits. Natural fibers like hemp and cotton provide flexibility and eco-friendliness but less strength than synthetic options such as nylon and polyester, which excel in demanding environments.

Fiber Processing

Initial preparation involves cleaning and aligning fibers into a continuous sliver, enhancing rope consistency and durability.

Drawing

Fibers are compressed through a drawing machine to increase density, then wound onto bobbins for further processing, including optional dyeing.

Rope Formation

Yarns are threaded through a metal plate into a compression tube where braiding or twisting occurs, creating the final rope structure.

Plated Rope

For specialized cordage, secondary braiding creates balanced S and Z twist patterns, ensuring stability in critical applications.

Quality Assurance

Finished ropes undergo strict testing for strength, flexibility, and resistance before customization for specific uses, ensuring optimal performance across various applications.