Introduction

This article provides an in-depth exploration of DC/DC power supplies:

- What is a DC/DC Power Supply?

- Types of DC/DC Power Supplies

- Fundamentals of DC/DC Power Supplies

- Mounting and Packaging Options

- Applications of DC/DC Power Supplies

- And much more...

Chapter One – What is a DC Power Supply?

A DC/DC converter is a type of power supply that uses direct current (DC) voltage input instead of alternating current (AC). Its primary function is to provide a stable output voltage suitable for powering electronic and electrical devices. Unlike AC voltage, DC voltage cannot be adjusted to higher or lower levels using a transformer.

Chapter Two – How do different power inputs affect a DC power management subsystem?

DC power supplies typically have two main power inputs: alternating current (AC) and direct current (DC). The type and quality of power input significantly impact the performance, efficiency, and flexibility of a DC power management subsystem. Choosing the right input source is crucial for ensuring reliable operation and optimal performance in electronic devices and power systems.

AC Input to DC Power Management Subsystem

An AC input (alternating current) can be converted to a regulated DC voltage through rectification and filtering. This DC voltage is then processed by a power regulator circuit to produce a stable output voltage for sensitive electronics. This conversion is common in industrial power supplies and consumer electronics where AC mains (typically 110V-240V) are transformed into required DC voltages. Output voltages can range from less than one volt for low-power circuits to over 1000 volts for specialized equipment like electric vehicle charging stations. Incorporating power factor correction and EMI filtering enhances efficiency and compliance with international electrical standards.

For critical applications such as medical devices or telecommunications, high-performance AC/DC converters and uninterruptible power supplies (UPS) ensure stable power delivery during voltage fluctuations.

DC Input and Applications

DC power supplies can also accept DC input voltages, commonly 5V, 12V, 24V, or 48V, found in automotive, industrial, and data communication systems. This allows direct integration with battery systems, renewable energy storage, or distributed power architectures. Output voltage can be precisely adjusted, from sub-1V for CPU cores to hundreds or thousands of volts for power transmission.

Modern DC power management subsystems use DC-DC converters like buck, boost, or buck-boost topologies to adjust voltage levels efficiently. Applications include server power supplies, electric vehicles, and IoT devices requiring reliable DC input handling. Features like overvoltage protection and current limiting enhance system safety and longevity.

Battery Input and Backup Power Solutions

Portable devices such as smartphones and laptops rely on battery power input for mobility. These devices often include AC adapters that provide regulated DC output to power the device and recharge its battery. These adapters use smart charging technology to optimize battery life and ensure safe operation.

When selecting a power subsystem, consider battery chemistry (e.g., lithium-ion, nickel-metal hydride) and required charging profiles. Advanced battery management systems (BMS) offer power monitoring, state-of-charge estimation, and thermal management for optimal performance and safety.

Ultralow Voltage Inputs and Energy Harvesting

Energy harvesting technologies enable DC power subsystems to operate from ultralow voltage inputs generated by renewable sources like solar, thermal, or kinetic energy. An energy harvesting power converter captures this energy, typically storing it in supercapacitors or micro-batteries for later use.

Energy harvesting is vital for wireless sensor networks, healthcare wearables, and remote IoT devices where wired power or frequent battery replacement isn't feasible. Efficient energy management extends operational life and enables self-powered electronics.

In summary, understanding different power inputs—AC, DC, battery, and energy harvesting—is essential for designing and evaluating DC power management subsystems. Matching the input type to application requirements ensures maximum efficiency, reliability, and cost-effectiveness. For guidance on power supply configuration or innovations in power management ICs, contact our technical team or explore our resources.

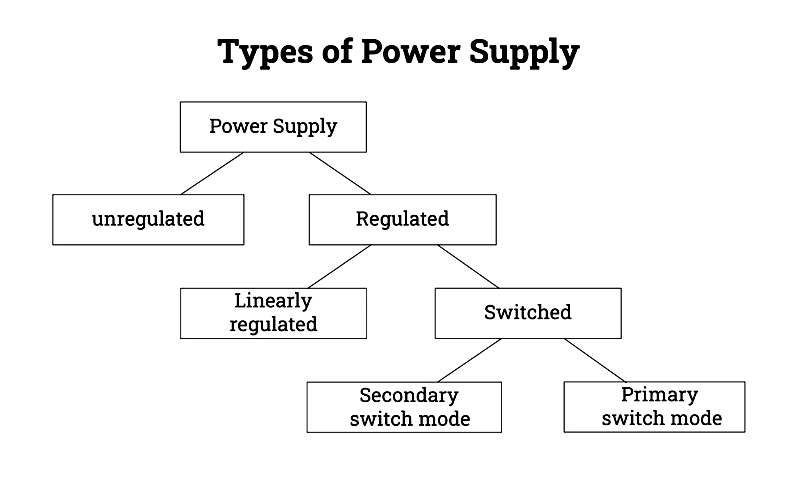

Chapter Three – What does the block diagram of a regulated DC power supply illustrate?

As discussed earlier, regulated DC power supplies often convert AC mains power into stable DC voltage. Most electronic circuits—found in computers, industrial automation, and consumer electronics—require constant DC voltage despite input fluctuations. While batteries can serve as DC sources, they're costly, require maintenance, and have limited lifespans. Converting AC to regulated DC is therefore essential for powering sensitive electronics and preventing voltage-related failures. This process involves four main stages, visualized in a Regulated DC Power Supply Block Diagram. Understanding each stage helps engineers select, design, or troubleshoot power supplies for optimal performance.

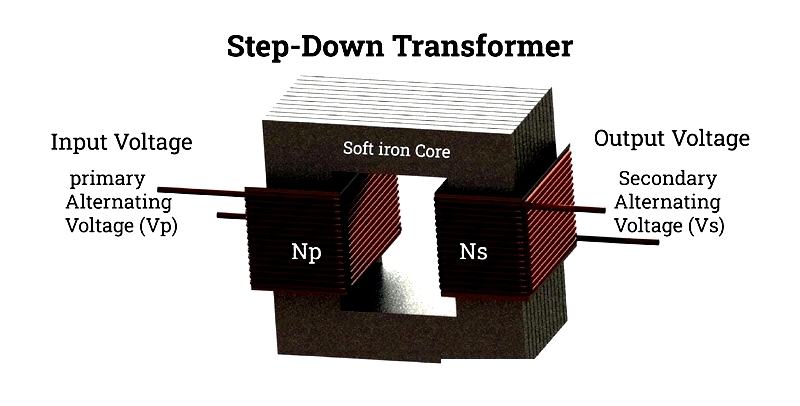

Step Down Transformation

The first stage in AC-to-DC conversion uses a step-down transformer to reduce high primary AC voltage to a safer secondary level. This transformer features primary and secondary windings, with the primary having more turns to achieve voltage reduction. It also provides galvanic isolation, enhancing safety by preventing electrical shocks.

Step-down transformers are categorized based on application needs:

Single-Phase Step-down Transformer

Reduces voltage for low-power devices, adapters, and small electronics.

Center-Tapped Step-down Transformer

Features a center-tapped secondary winding, providing dual-rail outputs (e.g., ±12V) for audio amplifiers.

Multi-Tapped Step-down Transformer

Offers multiple voltage options (e.g., 0-12V, 0-18V) for flexible power supply designs.

After transformation, the AC output is fed into the rectifier circuit.

Rectification

The second stage converts AC voltage to unidirectional DC using rectifiers. These circuits use diodes or thyristors, depending on whether fixed or variable output is needed.

Rectifiers are classified as:

- Half-Wave Rectifier -

- Converts only one half of the AC waveform, either positive or negative.

- Full-Wave Rectifier -

- Converts both halves of the AC waveform for higher efficiency.

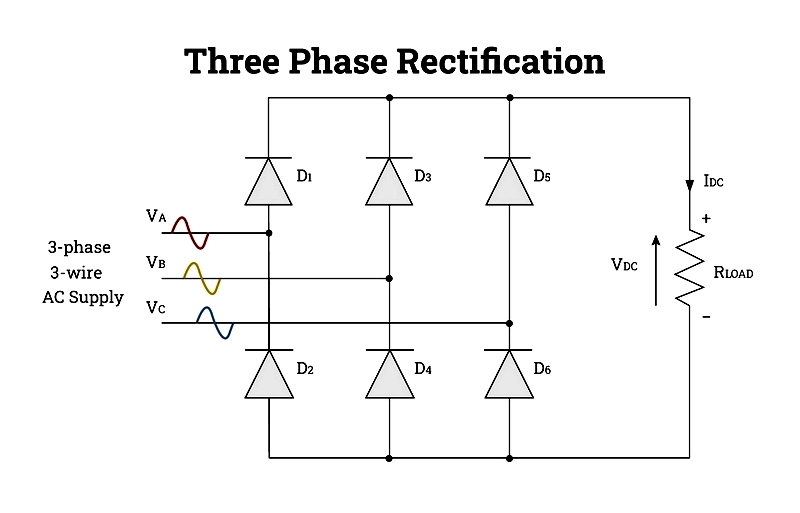

For high-power applications, three-phase rectification combines three single-phase rectifiers. Advanced systems like 12-pulse rectifiers minimize harmonic distortion for cleaner DC output.

DC Filtration

After rectification, filter circuits (e.g., capacitor, LC, or π-filters) smooth ripple voltage for stable DC output. This is critical for sensitive electronics like microcontrollers.

Regulation

The final stage ensures steady DC output despite input or load variations. Common regulators include:

-

<