Introduction

This article covers everything you need to know about copper and brass forging.

You will learn about:

- Copper and Brass Forging Basics

- Different Forging Techniques

- Products Created Through Brass Forging

- Materials Used in Forging

- And much more...

Chapter 1: What is Copper and Brass Forging?

Copper and brass forging shapes these metals by deforming them into complex forms. This process requires precise temperature control, as these metals melt between 1675°F and 1981°F (913°C to 1082°C). Their excellent ductility and malleability make them ideal for forging.

These metals' unique properties allow for intricate designs. Forged copper and brass products offer exceptional quality with precise dimensions and polished finishes that rival other metalworks.

Chapter 2: Types of Copper and Brass Forging

Various forging techniques work with copper and brass alloys, valued for their ductility and corrosion resistance. The method chosen depends on the alloy's properties. Forging these metals has ancient origins, but modern industries use advanced techniques to create components for automotive, electrical, and aerospace applications.

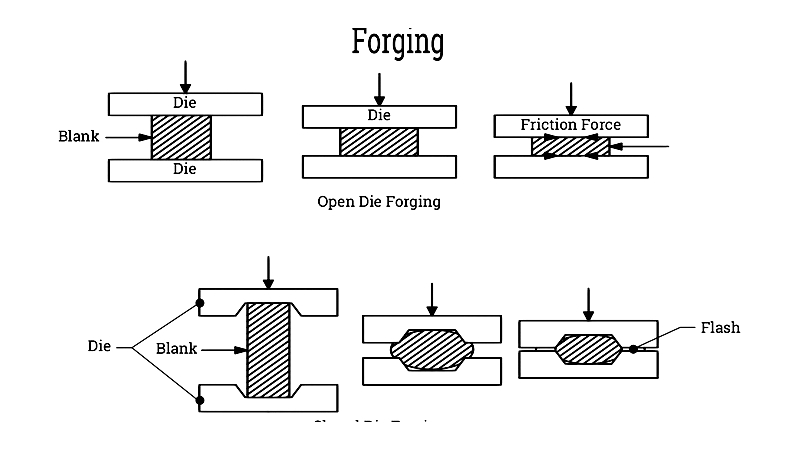

All forging processes use specialized dies to shape the metal. Force application alters the metal's internal structure, enhancing strength and surface finish. These improvements are crucial for high-performance applications.

Cold Forging

Cold forging shapes copper or brass at room temperature using dies. This energy-efficient method preserves the metals' electrical and thermal properties while ensuring precise dimensions.

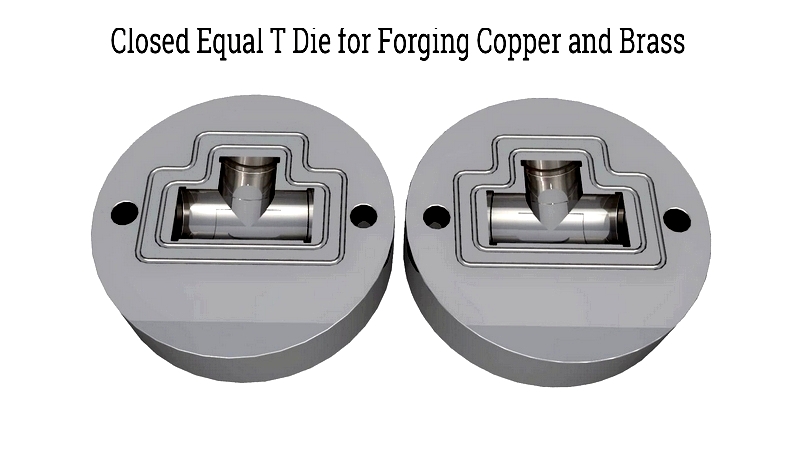

Die

The process begins with creating hardened steel dies. Complex designs require additional toughness to prevent cracking. Dies for copper and brass typically use H21, H11, or H13 steel with a Rockwell hardness of 48-52.

Forging

Cold forging enhances hardness and dimensional accuracy. The metal is placed in a die and pressed by a ram to form the desired shape. This method works well for electrical and plumbing components.

Hot Forging

Hot forging heats the metal before shaping, producing dense parts with excellent mechanical properties. The process yields smooth finishes suitable for aesthetic components.

Heating

metal slugs are heated to 1350°F-1700°F (732°C-927°C). Precise temperature control ensures proper formation.

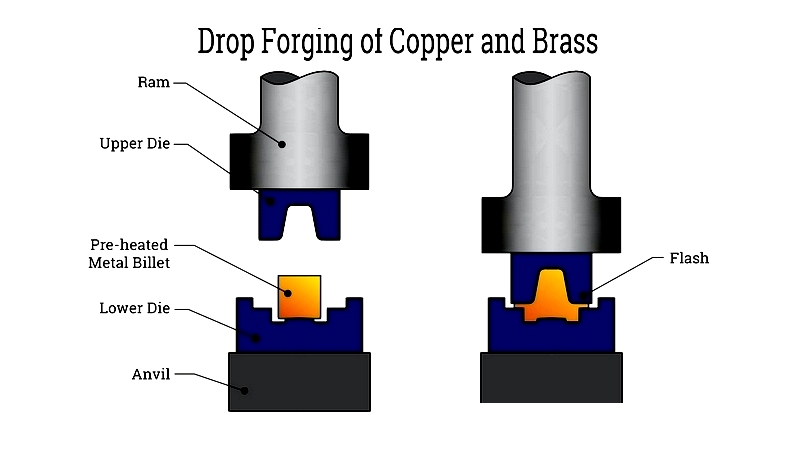

Forging

The heated metal is placed in preheated dies. A single ram stroke typically suffices to shape copper and brass, making the process efficient for mass production.

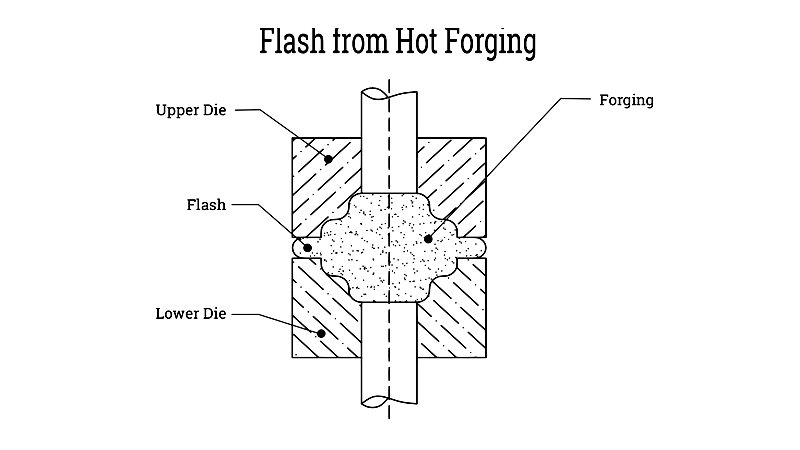

Trimming

Excess metal (flash) is trimmed for a clean finish. Precise trimming ensures dimensional accuracy for critical components.

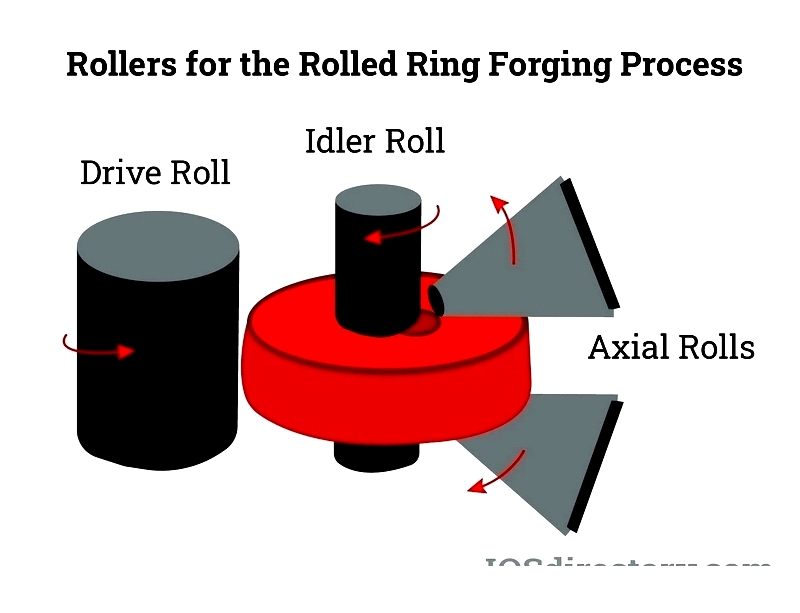

Rolled Ring Forging

This specialized method creates seamless rings using rollers and mandrels. It's ideal for producing durable seals and bearings.

Cold Forging

metal stock is shaped into rings through piercing and forming.

Forging

Rollers gradually shape the ring to precise dimensions. Controlled deformation ensures strength and uniformity.

Warm Forging

This middle-ground technique combines benefits of cold and hot forging. It produces complex components with excellent surface quality while reducing energy consumption.

Factors Influencing Forging Technique Selection

Manufacturers consider alloy properties, application needs, and production volume when choosing methods. Different techniques suit various components, from electrical contacts to large busbars.

Chapter 3: Brass Types for Forging

Brass alloys vary in composition for different applications. Their versatility makes them ideal for plumbing, electronics, and decorative items.

Alpha Brass (CuZn)

With 55%-65% copper, this ductile alloy resists corrosion well. It's used for architectural features and electrical components.

Alpha Beta Brass (CuZn40)

This balanced alloy suits hot forging for valves and gears. Additional elements can enhance its properties.

Beta Brass (CuZn15)

High-zinc content makes this alloy hard and strong, ideal for fasteners and heavy-duty parts.

Leaded Brass (CuZn39Pb3)

The lead content improves machinability for precision parts like plumbing fittings.

Naval Brass (CuZn40Sn1)

Tin addition boosts marine corrosion resistance for ship components.

Red Brass (CuZn15)

High copper content makes this alloy ideal for water systems and decorative items.

White Brass (CuMnZnAlPb)

This silvery alloy suits jewelry and decorative applications.

Yellow Brass (CuZn33)

Known as cartridge brass, it's used for ammunition and musical instruments.

Understanding brass types helps select the right material for specific forging needs, balancing performance with cost and environmental factors.