Introduction

This article provides a detailed discussion about door latches.

After reading, you should understand the following:

- What is a Door Latch?

- Types of Door Latches

- Advantages of Door Latches

- Industrial Door Latches

- Door Latch Applications

- And much more…

Chapter One: What is a Door Latch?

A door latch is a mechanical device designed to securely connect two surfaces or objects, ensuring a reliable and stable connection. Typically mounted on a flat surface, the latch works with a corresponding hardware piece on an adjacent surface to create a firm connection.

Door latches come in various styles, differing in materials, designs, functions, and operating mechanisms. They are widely used in situations requiring strong surface connections, demonstrating their versatility and importance.

Among the many types, commercial door latches are particularly notable. These latches can operate mechanically or electronically and are designed for commercial settings like offices, businesses, and industrial locations. Built with durable materials, they offer enhanced security and longevity compared to residential latches.

Chapter Two: What are the different types of door latches, and what are their specific advantages and disadvantages?

Door latches are essential components of mechanical fastening systems used to secure doors, enclosures, and cabinets. Door latch manufacturers offer a variety of standard designs suitable for interior and exterior doors, including entry doors, fire doors, and security doors. They also provide custom solutions for specific security or environmental needs. Choosing the right latch is crucial for optimizing door security, access control, and safety in both commercial and residential settings.

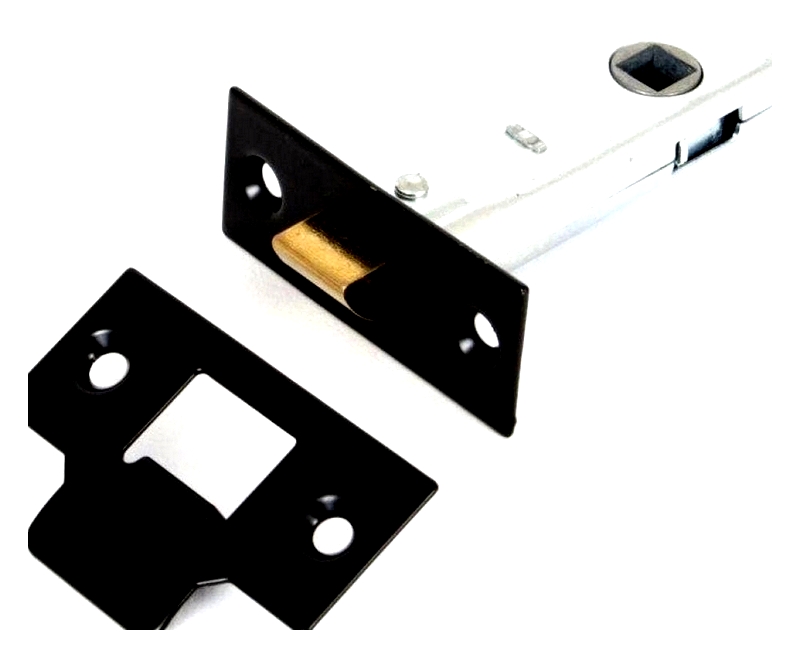

Tubular Latches

A tubular latch, typically made of iron, brass, or stainless steel, is installed within a mortise in the door and operated with a handle or knob. Common in residential and commercial applications, it features a spring-loaded follower and a triangular-ended latch bolt that retracts when the door opens and returns when closed. Tubular latches are standard in door hardware for privacy and passage doors.

Advantages of Tubular Latches

Exceptional Security

Tubular latches provide excellent security because they are installed within the door, making them harder to force open than cylindrical latches. This makes them ideal for high-traffic areas and entryways requiring robust door locking mechanisms.

Visually Appealing

Their design enhances a door's appearance, offering a classic and refined look. Available in various finishes, they complement both traditional and contemporary architectural styles.

Available in Several Sizes

Tubular latches come in multiple sizes, accommodating different door dimensions. Their adaptability makes them suitable for fire-rated doors, bathroom doors, and custom entryways.

Drawbacks of Tubular Latches

Challenging to install

- Installation requires cutting a hole in the door, which can be time-consuming.

- They require doors of a certain thickness.

- If a key is left behind the door, opening it can be difficult.

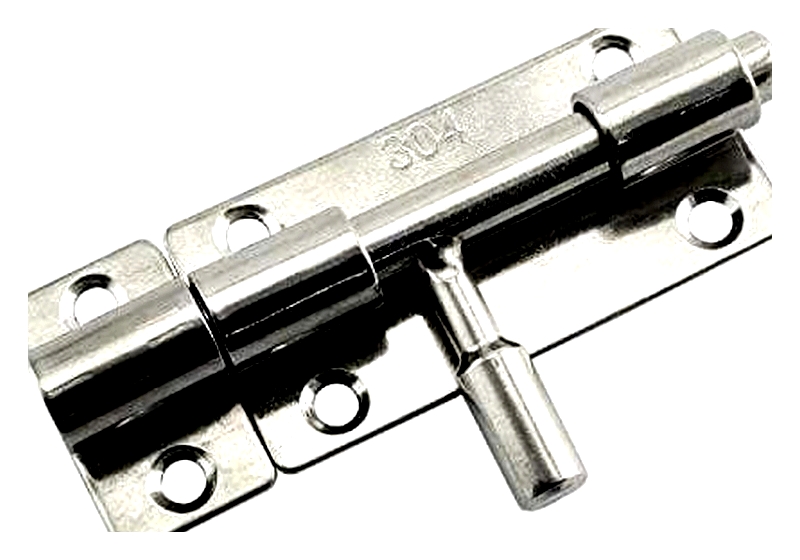

Bolt Latches

A bolt latch secures a door with a metal bolt, ranging from deadbolts to standard doorknob latches. One of the oldest types of door security devices, it provides reliable protection in residential and commercial settings.

Bolt latches work by engaging a rotating or sliding bolt with a stationary component. They can be integrated with various locksets and door handles, offering versatility.

Spring bolts and deadbolts are the main types. Spring bolts use a spring clip to snap back into place, while deadbolts require a key and offer greater security.

Advantages of Latch Bolts

- Automatically lock upon door closure.

- Easy to engage with a key or knob.

- Deadbolts are sturdy and resistant to picking.

- Extend further into the doorframe, increasing security.

Disadvantages of Latch Bolts

- Rim latches cannot prevent unauthorized access.

- Deadbolts require manual operation, limiting egress speed.

- Spring latch bolts offer limited security.

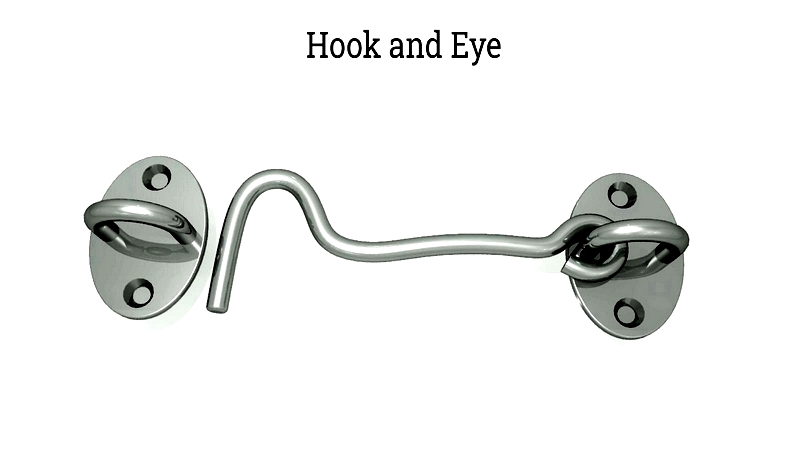

Hook and Eye Latches

Commonly used on gates and garden doors, hook and eye latches consist of a hook attached to the gate and an eye on the frame. Simple and effective, they are popular in outdoor and light-duty settings.

Advantages of Hook and Eye Latches

- Intuitive and easy to use.

- Adaptable for use on either side of the door.

- Deter trespassers in garden gates and sheds.

Disadvantages of Hook and Eye Latches

- Not suitable for high-security applications.

- Best used as secondary latching solutions.

Rim Latches

Rim latches, surface-mounted locking mechanisms, are used when doors are too thin for mortise locks. Found in older homes and modern constructions, they are cost-effective and easy to install.

Advantages of Rim Latches

They offer a straightforward solution for securing interior doors and come in various styles.

Disadvantages of Rim Latches

- Provide limited security.

- Vulnerable to picking and forced entry.

Slam Latches

Slam latches automatically secure doors upon closing, making them ideal for industrial applications like equipment enclosures and truck bodies.

Types of Slam Latches

Single-Point

Compact and non-locking, suitable for small cabinets.

Push-Button

Operated by a push button for quick access.

Multi-Point

Offers enhanced security with multiple bolts.

Finger-Pull

Manual operation for non-locking doors.

Paddle

Surface-mounted with a paddle mechanism.

Rotary

Includes a key mechanism for secure storage.

Advantages of Slam Latches

- Easy to use and install.

- Durable and vibration-resistant.

- Self-closing, reducing user