Introduction

This guide covers everything you need to know about lost wax casting.

You'll discover:

- The fundamentals of Lost Wax Casting

- The step-by-step Lost Wax Casting Process

- Common metals used in Lost Wax Casting

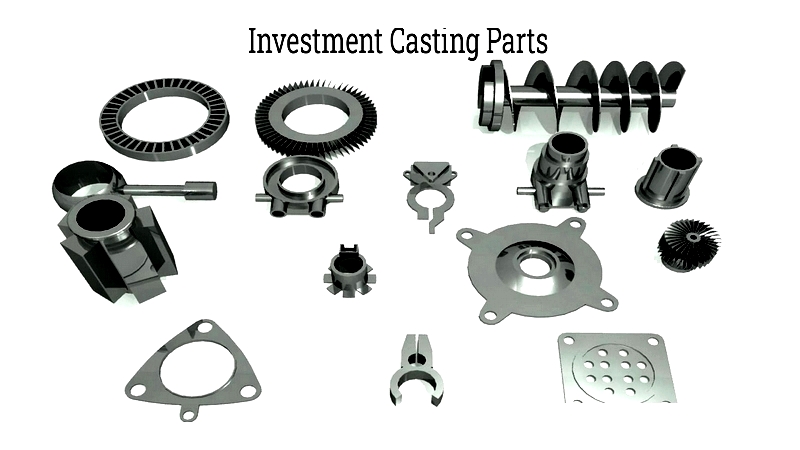

- Typical applications of Lost Wax Casting

- Additional valuable information

Chapter 1: Understanding Lost Wax Casting

Lost wax casting is a manufacturing process that uses wax patterns to create ceramic molds for producing precision components. Also known as investment casting, this method delivers exceptional accuracy and tight tolerances. The technique has evolved over time, with "investment casting" becoming the modern industry term for this highly precise manufacturing approach.

What sets lost wax casting apart is its use of wax patterns to form molds, enabling the production of complex, detailed designs that would be difficult to achieve with other methods.

Chapter 2: The Lost Wax Casting Process

Lost wax casting, or investment casting, is a precision manufacturing technique that produces intricate metal components with excellent dimensional accuracy, tight tolerances, thin walls, and smooth finishes. Widely used in aerospace, medical, automotive, and jewelry industries, this process excels at reproducing complex geometries from CAD designs by first creating wax patterns.

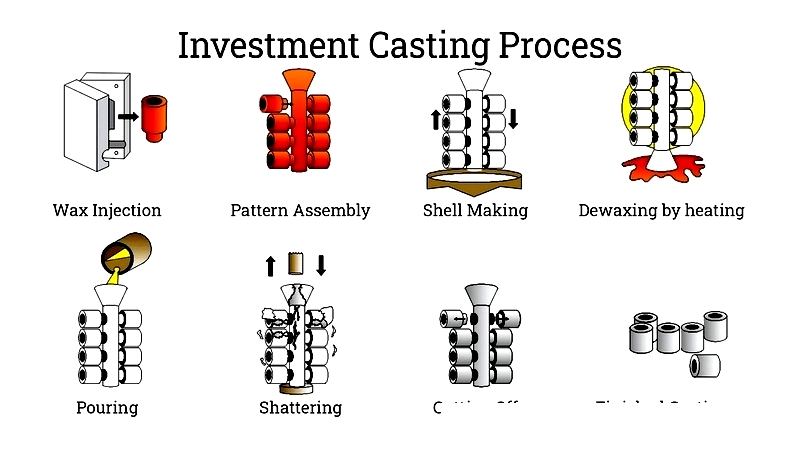

Step-by-Step Process Overview

The modern lost wax casting process transforms digital designs into finished metal components through carefully controlled stages. Understanding these steps helps in design optimization, supplier selection, and process comparison with alternatives like sand casting or 3D printing.

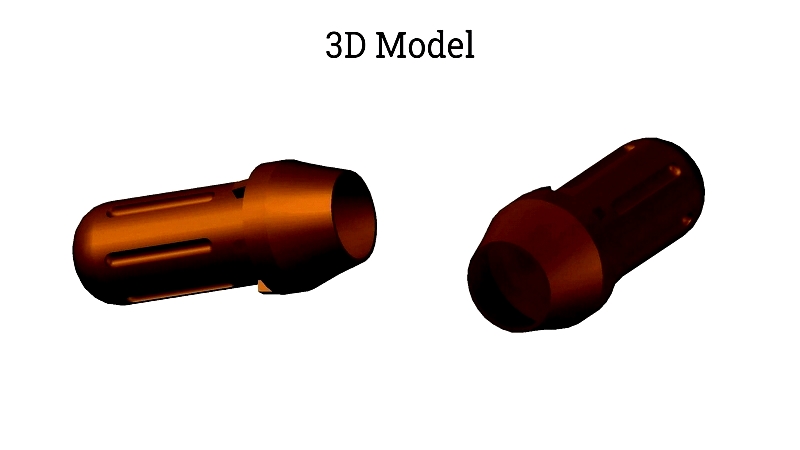

CNC Rendering

The process begins with creating a 3D CAD model of the part, which serves as the blueprint for the aluminum die. This digital design ensures accurate representation of complex features and critical tolerances.

Die Creation

based on the CAD design, a die is manufactured from hardened aluminum or steel. This negative impression of the part is crucial for achieving precision in complex castings like turbine blades or medical implants.

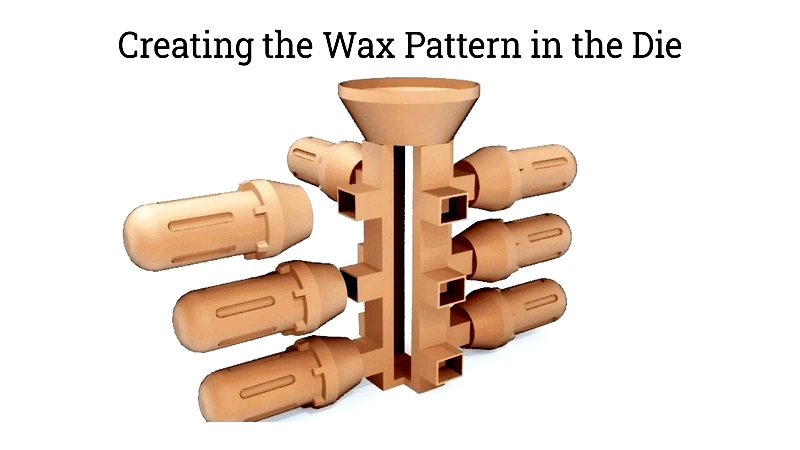

Wax Pattern Production

Semi-liquid wax is injected into the die to create patterns, accounting for material shrinkage. This repeatable process allows for batch production while maintaining consistency.

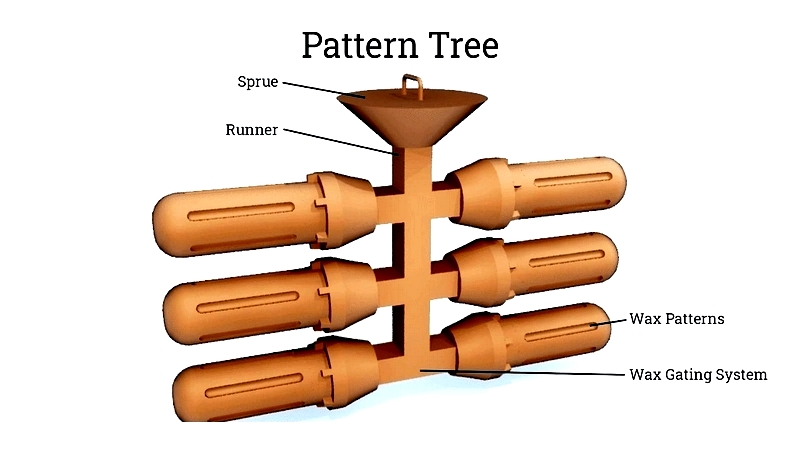

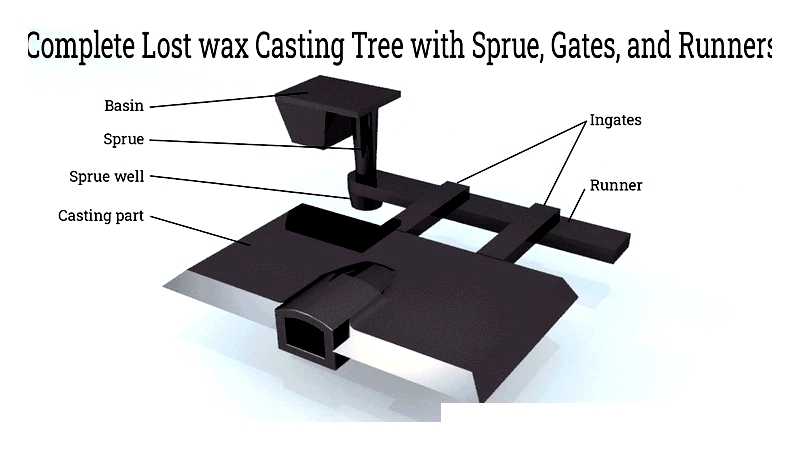

Pattern Tree Assembly

Wax patterns are attached to a central sprue via runners, forming a tree structure that enables multiple castings in a single pour. This approach improves production efficiency.

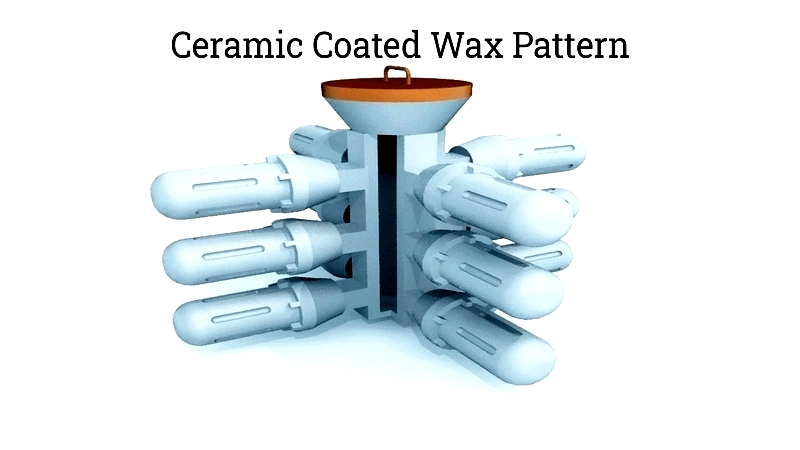

Shell Building

The wax tree is repeatedly dipped in ceramic slurry to build a heat-resistant shell. Controlled shell thickness ensures mold durability during metal pouring while maintaining dimensional accuracy.

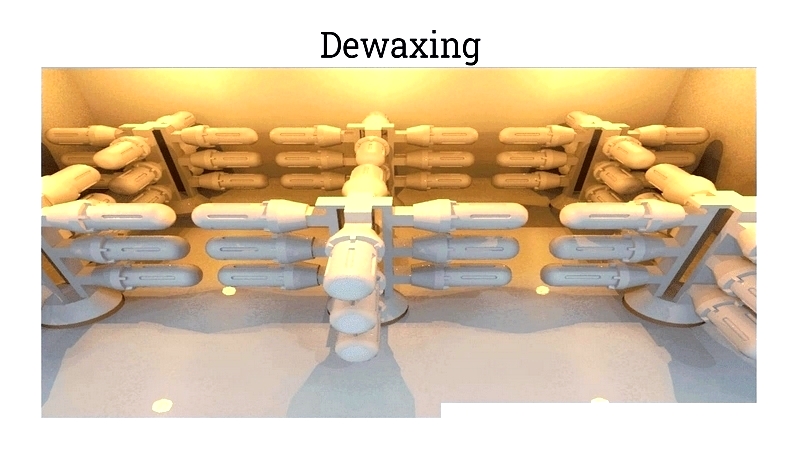

Dewaxing

The ceramic shell is heated to melt out the wax, creating a hollow mold cavity. This step gives the process its name and is critical for achieving defect-free surfaces.

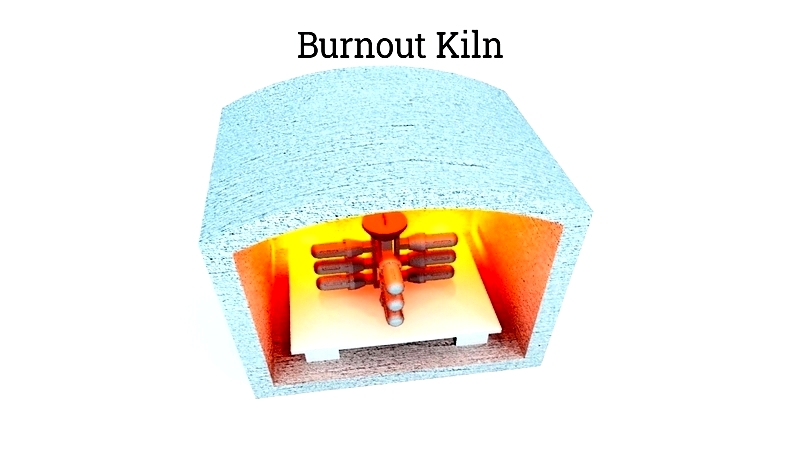

Burnout

Remaining wax residues are removed by heating the mold above 1037°C (1900°F), which also strengthens the ceramic shell for metal pouring.

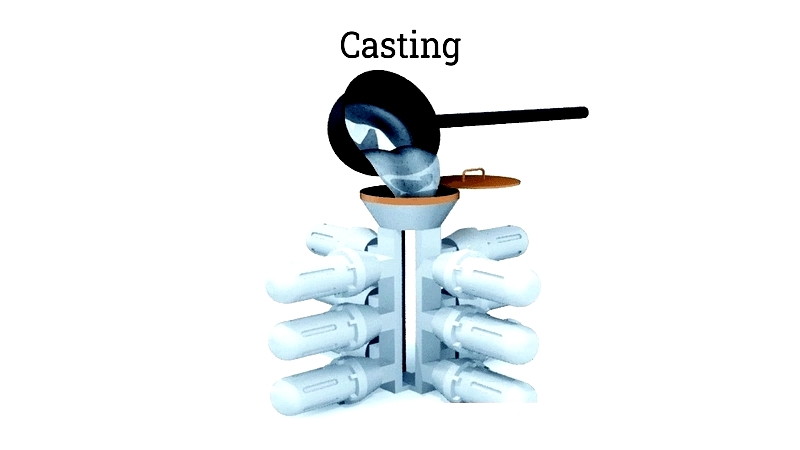

Casting

Molten metal is poured into the preheated ceramic mold using gravity or vacuum techniques, depending on alloy and part requirements.

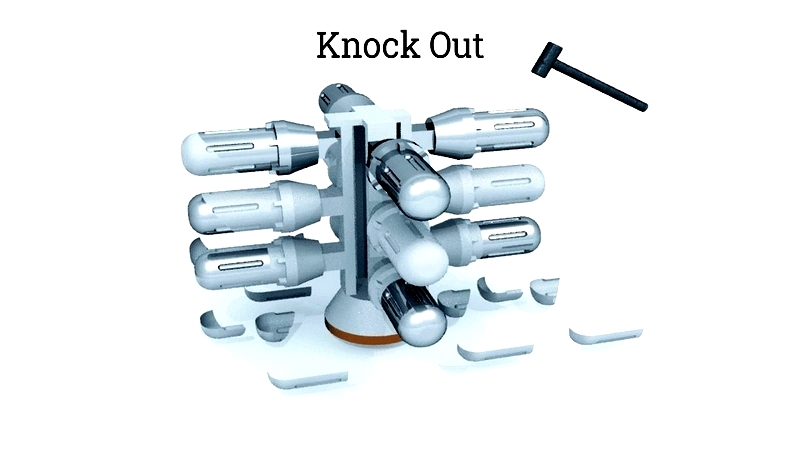

Knockout

The ceramic shell is removed through mechanical or chemical methods, revealing the cast metal components while preserving fine details.

Cutting

Components are separated from gates and runners using cutting tools, with excess material typically recycled.

Blasting

Shot or sand blasting removes surface oxides and residual ceramic material, improving the component's finish.

Surface Treatments

Additional protective coatings like anti-rust solutions, plating, or powder coating may be applied based on application requirements.

While this describes the standard process, variations exist including 3D printed patterns and specialized ceramic formulations. When selecting suppliers, consider their capabilities, certifications, and value-added services to ensure optimal results for your precision casting needs.

Chapter 3: Leading Lost Wax Casting Machines

Lost wax casting produces parts with exceptional accuracy and detail, making it ideal for jewelry, aerospace, and medical applications. Several manufacturers offer specialized equipment for this process. Here are five notable brands available in North America:

Kerr Corporation:

Centrifico Casting Machine

This centrifugal casting machine features digital temperature control and adjustable speeds, making it ideal for jewelry and dental applications. Its compact design and safety features ensure consistent, user-friendly operation.

Neutec/USA:

J2R Casting Machine

Designed for small-scale casting, this machine uses induction heating and programmable cycles. Its vacuum assist feature enhances casting quality for precision jewelry work.

Rio Grande:

Neutec® PulsePoint™ Plus 140

This versatile machine employs pulse-arc technology to minimize metal oxidation. Its customizable programs and touchscreen interface make it suitable for professional jewelers working with precious metals.

Romanoff International:

Vulcan 3-550 Casting Machine

Built for high-volume production, this industrial machine handles large flasks with precision temperature control and rapid cooling capabilities.

Indutherm GmbH:

VC 3000 Casting Machine

This advanced system features induction heating and vacuum/pressure options, making it suitable for industrial-scale production with various metal alloys.

Selection Considerations

When