Introduction

- Plastic Overmolding Processes

- What is Overmolding?

- Leading Manufacturers of Plastic Overmolding Machines

- Design Considerations for Plastic Overmolding

- Types and Grades of Plastic for Overmolding

- Industrial Applications of Plastic Overmolding

- And Much More...

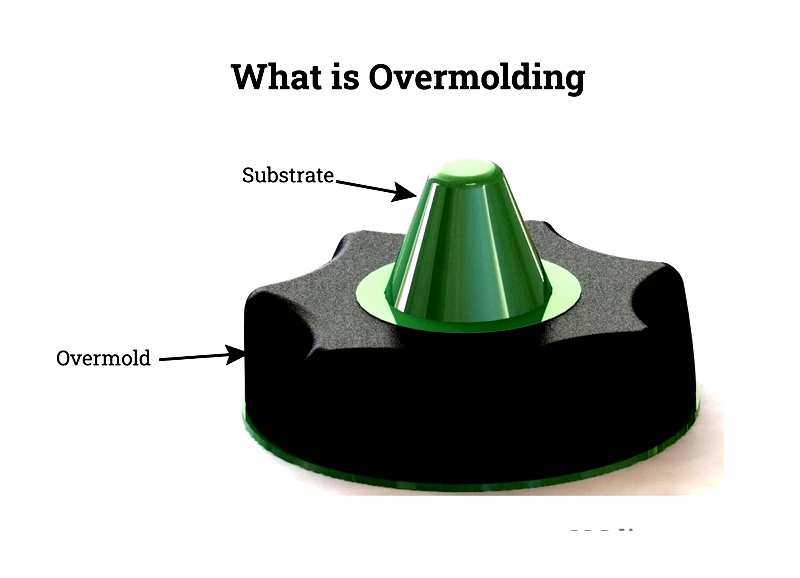

Chapter 1: What is Overmolding?

Plastic overmolding is a specialized manufacturing process that combines different plastic materials to create a single integrated component. This technique improves the performance, durability, and visual appeal of plastic parts by layering materials with similar or complementary properties.

The process involves encapsulating a pre-formed substrate—made from plastic, metal, or other materials—with an additional plastic layer. Thermoplastics are frequently used because they can be reheated and reshaped repeatedly without degrading their essential characteristics.

Chapter 2: Plastic Overmolding Processes

Plastic overmolding is a versatile manufacturing technique that merges multiple materials into a single component with improved structural or functional properties. This advanced method is crucial for producing high-performance plastic parts in industries like automotive, electronics, medical devices, and consumer goods. Key processes include co-injection molding, two-shot molding, co-extrusion, and insert molding. Selecting the appropriate method and compatible materials is vital for achieving strong bonding, dimensional accuracy, thermal stability, chemical resistance, and desired mechanical performance. important factors include material compatibility, adhesion properties, design guidelines, and application requirements. Choosing the right overmolding process enhances product quality, reduces cycle times, and lowers manufacturing costs—benefits highly valued by engineers, OEMs, and product developers.

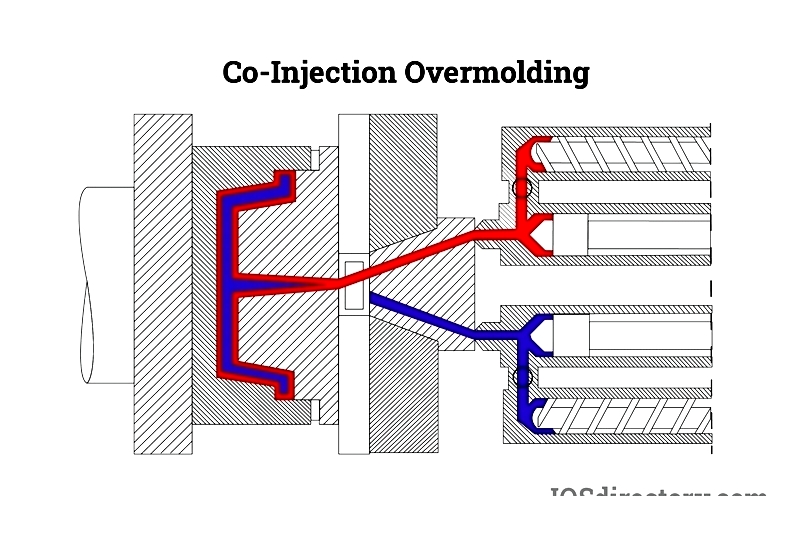

Co-Injection Overmolding

Co-injection overmolding, or multi-material injection molding, combines multiple polymers to create a single part with a layered structure. This method allows manufacturers to encase a core material with an outer layer that offers superior aesthetics or chemical resistance. Using advanced machinery with dual barrels and a single nozzle, the skin plastic is injected first, followed by the core material. A final injection of the skin plastic ensures complete coverage, resulting in a part with a solid core and durable shell.

This technology is ideal for components requiring soft-touch surfaces, improved ergonomics, enhanced durability, or multi-functionality. By selecting materials like thermoplastics, elastomers, or specialty polymers, manufacturers can optimize performance and user appeal. Co-injection molded parts are widely used in handles, medical device housings, power tool grips, and automotive components where both function and aesthetics matter.

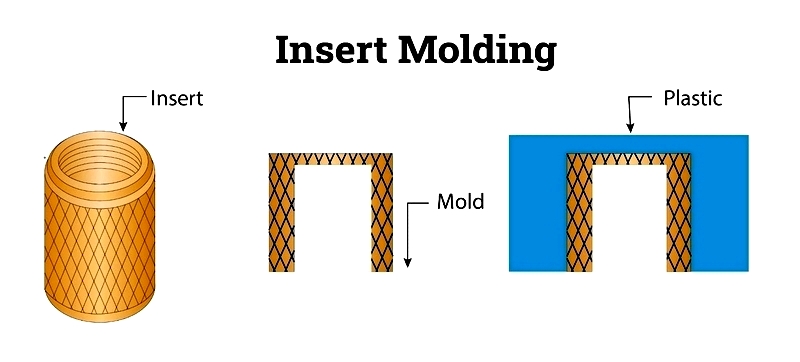

Insert Molding

Insert molding involves placing a preformed component—such as a metal, plastic, or electronic insert—into the mold cavity before injecting plastic resin. The molten plastic flows around and bonds with the insert, creating a robust connection. This method is particularly effective for manufacturing connectors, electronic sensors, fasteners, and custom tools.

Insert molding is ideal for complex parts requiring embedded electrical contacts, bushings, or threaded inserts. Automation technologies, like robotic arms, improve precision and efficiency, reducing scrap and labor costs. In plastic overmolding, the component is positioned in a new mold designed to accommodate the additional material layer. Molds may feature rotating sections or co-injection capabilities for advanced multi-material integration, commonly used in aerospace, medical, and electronics industries.

Two-Shot Molding

Two-shot molding, also known as double-shot or 2K molding, sequentially injects two different polymers into a single mold to create multi-material parts. Specialized machines and molds with separate cavities are used. The primary material (often rigid thermoplastic) is injected and partially cooled, followed by a secondary material (like TPE or colored polymer).

This process excels in producing parts with soft-touch grips, color accents, gaskets, or seals. It reduces assembly steps, improves bonding, and lowers costs for high-volume production. Industries like medical devices, automotive, and electronics benefit from its design flexibility and superior finishes.

Co-Extrusion

Co-extrusion simultaneously processes multiple polymers through a single die to create composite structures with tailored layers. This technique leverages each material's unique properties to achieve features like chemical resistance, flexibility, or moisture barriers. It's commonly used for tubing, sheet materials, window profiles, and medical catheters.

Multiple material streams are fed into the extruder, heated, and merged in the die to form a bonded, multi-layer structure. This method reduces secondary operations and enhances functionality, making it popular in medical, packaging, construction, and electronics sectors.

Selecting the right overmolding process—whether co-injection, insert molding, two-shot molding, or co-extrusion—depends on project specifications and industry needs. The appropriate method and materials enable innovative, reliable plastic components that stand out in competitive markets.

Chapter 3: Leading Manufacturers of Plastic Overmolding Machines

The demand for advanced plastic overmolding machines continues growing as industries seek high-performance, multi-material components. These machines are vital in automotive, electronics, medical devices, and consumer goods, where efficiency, durability, and design complexity are critical. This guide highlights prominent brands known for their specialized solutions and technological advancements.

Arburg - Model: Allrounder 520 A

The Arburg Allrounder 520 A is a versatile machine for thermoplastic and elastomer overmolding. Its advanced controls and modular design ensure precision, energy efficiency, and flexibility for both prototyping and high-volume production. Servo-hydraulic and electric drive technologies provide consistent performance.

Engel - Model: Victory Series

The Engel Victory series excels in multi-component overmolding with its tie-bar-less design and fast mold changes. Servo-electric drives and intelligent controls deliver high precision and energy efficiency, making it suitable for automotive, medical, and consumer products.

Sumitomo (SHI) Demag - Model: IntElect Multi Series

The IntElect Multi series is optimized for high-speed, high-accuracy overmolding. Its all-electric system handles challenging material combinations like TPE over rigid plastics, ideal for electronics and medical applications. Integrated software enhances process transparency and quality assurance.

Milacron - Model: Elektron Multi-Shot Series

The Elektron Multi-Shot series supports advanced overmolding with servo-driven precision and multiple injection units. It accommodates hard/soft plastic combinations and insert overmolding, perfect for electronic housings, automotive seals, and medical assemblies.

Wittmann Battenfeld - Model: SmartPower COMBIMOULD Series

The SmartPower COMBIMOULD series integrates injection molding and overmolding in a compact system. Energy-efficient servo motors and automation features ensure reliability and flexibility for medical, automotive, and electronics applications.

These manufacturers offer innovative solutions for precision, efficiency, and complex engineering. evaluating technical specifications and application case studies helps select the best machine for your production needs.

Chapter 4: Design Considerations for Plastic Overmolding

Designing for plastic overmolding requires attention to material compatibility, part geometry, gate and runner design, wall thickness, and undercuts. Below are key design elements to consider.

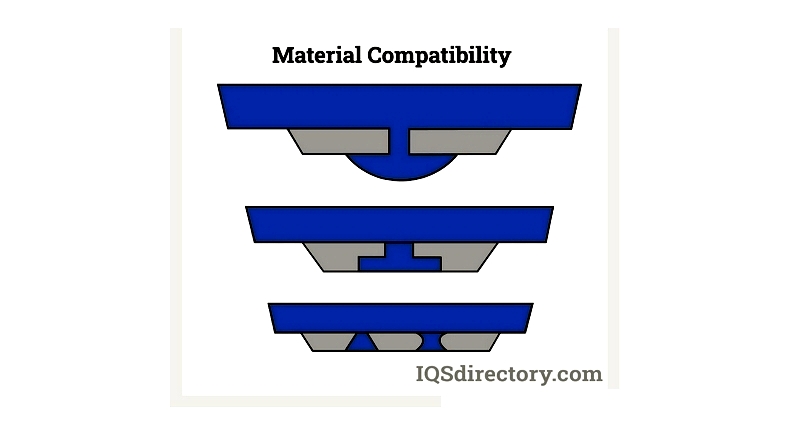

Material Compatibility

Material compatibility ensures strong adhesion between layers. Factors include melting temperatures, shrinkage rates, and thermal expansion coefficients.

Part Design

Part design must promote even plastic flow, avoiding air pockets. Draft angles and radii facilitate smooth mold ejection.