Introduction

This article provides an in-depth exploration of power presses.

You'll discover the following topics:

- How Power Presses Work

- Different Types of Power Presses

- Applications, Advantages, and Safety Considerations

- Additional important Information

Chapter 1: Power Press Mechanics Explained

This section examines the fundamental concepts and industrial applications of power presses in metal fabrication.

What Is a Power Press?

A power press is a machine tool that shapes, cuts, and punches metal through cold stamping. Available in various configurations, these machines are particularly valuable for high-volume metal part production. They're mainly categorized as hydraulic or mechanical based on their power source.

Power presses operate using mechanical, hydraulic, or servo motor principles. Mechanical models transform rotational motion into linear movement through a clutch, flywheel, and crankshaft system. Hydraulic versions use pressurized fluid to mold metals, while servo-powered presses employ motors to drive the press slider via eccentric gears.

All press types achieve the desired workpiece shape as upper and lower dies mold the metal under pressure.

Historically, metal forming relied on manual labor until power press technology introduced enhanced precision and mechanical efficiency.

Power Press Designs

Power press designs differ by their force application methods. Mechanical presses accumulate force in a flywheel before transferring it to the ram. Hydraulic models use fluid pressure for motion, while servo motor presses convert rotational to linear motion.

Selecting the right press requires careful consideration. While mechanical presses represent the traditional choice, servo motor models incorporate the latest technological advancements. Hydraulic presses emerged as alternatives to mechanical versions.

Hydraulic Press Components

Invented over two centuries ago during the Industrial Revolution, modern hydraulic presses can generate tremendous pressure for mass-producing diverse components.

These systems function through pumps, endplates, and pistons that create fluid pressure for metal forming. The pump serves as the core component, forcing oil into cylinders under high pressure.

Cylinder

The cylinder guides a vertically moving piston that generates the necessary force for metal shaping.

Reservoir

This component stores hydraulic fluid while filtering impurities, removing air/moisture, dissipating heat, and channeling fluid to the cylinder.

Valve

Valves control fluid flow between pump and cylinder, regulating pressure while adjusting press speed and force output. Pressure gauges monitor fluid pressure within set limits.

Hydraulic Pump

The pump circulates fluid to the reservoir, converting mechanical energy into hydraulic energy to create pressurized flow.

Press Plates

These plates secure workpieces and provide stability for operations like stamping and bending.

Hoses

Constructed from durable materials, these high-pressure conduits connect the pump, cylinder, and reservoir.

Ram

The ram moves along the press frame to apply force on the die, with some models featuring multiple rams.

Bed

This stable platform anchors the die during ram operations.

Servo Press Components

Servo presses use precision motors for accurate ram positioning, ideal for aerospace and electronics applications. The motor connects to a linear actuator that converts rotary to linear motion.

These presses replace traditional components with servo units, simplifying design while improving ram control for customized workpiece contact.

Essential for precision tasks, servo presses outperform conventional models in accuracy and repeatability.

Servo Motor

These motors power the ram directly or through reducers, with different configurations suiting various press capacities.

Actuator

Typically using ball screw systems, actuators provide smooth, precise motion conversion.

Controller

Controllers process sensor data to manage servo motors, offering superior stroke control compared to traditional presses.

Sensors - Monitor position and speed for precision control.

Human Machine Interface (HMI) - Enables parameter monitoring and adjustment, with advanced systems incorporating SCADA technology.

Mechanical Press Design

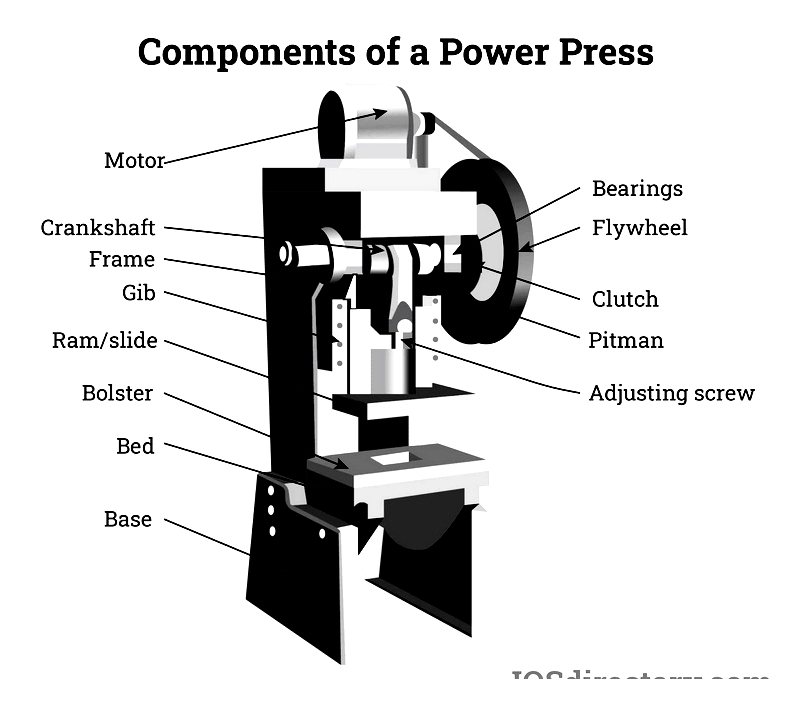

Key components include the clutch, crankshaft, flywheel, and rams connected by pitmans or rods.

The crankshaft connects to a continuously rotating flywheel driven by a motor. The clutch engages the crankshaft to activate the press slide for forming operations.

Ram

This component delivers forming force with adjustable stroke length and power for punch tool operations.

Flywheel

This energy-storing pulley maintains consistent ram speed, allowing smaller motors to deliver peak power when needed.

Clutch

Mechanical clutches engage/disengage the drive shaft from the flywheel, with OSHA regulating clutch types for safety.

Brakes

Essential safety components that stop motion after clutch disengagement, including emergency brake systems.

base

The structural foundation supporting clamping mechanisms and dies, with table size determining maximum workpiece capacity.

Drive and Control Systems

These convert motor power into ram movement, with modern systems incorporating microprocessor controls.

Bolster Plate

A heavy plate that secures die assemblies for accurate operations and operator safety.

Power Press Operation

The process involves coordinated action between ram, bed, flywheel, clutch, and crankshaft components. The die-equipped ram presses metal sheets as the engaged crankshaft drives the flywheel's rotation, enabling repeated shaping operations.

Determining Press Size

Key factors include tonnage ratings, worktable dimensions, and opening height. Tonnage depends on material properties, while table size must accommodate workpieces. Proper calculation ensures operational efficiency for serial production.

Press Selection Fundamentals

Choosing the right press requires understanding its intended use and operational requirements. Incorrect selection can reduce efficiency. Consider these factors:

Processing Method Selection

Technique

Identify appropriate stamping methods to determine suitable punch types.

Production Volume

evaluate automatic feeding benefits for runs exceeding 3000-5000 units.

Material Properties

Analyze processing conditions and material usage patterns.

Material Handling

Streamlined handling improves manufacturing workflow.

Die Buffer Requirements

Assess buffering needs for complex operations without dual-action capability.

Punching Capacity

Pressure and Stroke

Calculate requirements using pressure stroke curves for multi-project needs.

Eccentric Load

Select presses with capacity margins for unbalanced loads.

Buffer Capacity

Size buffers appropriately, considering dual-action punches for specific applications.

Dimensional Accuracy

Consider tolerance requirements, with servo presses offering superior precision.

Understanding Punch Functions

Specifications

Review punch specifications thoroughly for capacity and accessory compatibility.

Reliability and Maintenance

Safety

Prioritize machines with comprehensive safety features.

Noise Control

Select models with vibration/noise reduction for regulatory compliance.

Chapter 2: Power Press Varieties

Essential for metal forming, power presses can be classified by frame type, drive mechanism, or operation method. Understanding mechanical, hydraulic, and pneumatic press types helps manufacturers select optimal equipment for specific production needs.

Power Press frame Types

frame selection impacts press stiffness, strength, and capacity - crucial considerations for stamping and punching operations.