Introduction

This article provides an in-depth exploration of laser marking and engraving machinery.

You'll gain insights into various aspects including:

- The fundamentals of laser marking and engraving machinery

- Working principles of laser marking and engraving systems

- Key factors in selecting laser marking and engraving equipment

- Materials suitable for laser marking and engraving

- Different laser marking and engraving techniques

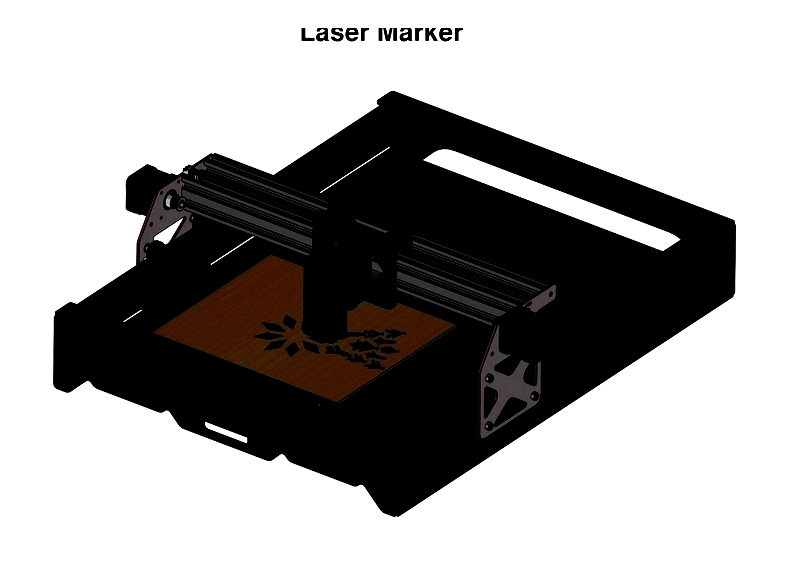

- Varieties of laser marking and engraving machines

- Pros and cons of laser marking and engraving technology

- Maintenance requirements for laser equipment

- And much more...

Chapter One - Understanding Laser Marking and Engraving Machines: Operation, Functionality, and Selection Criteria

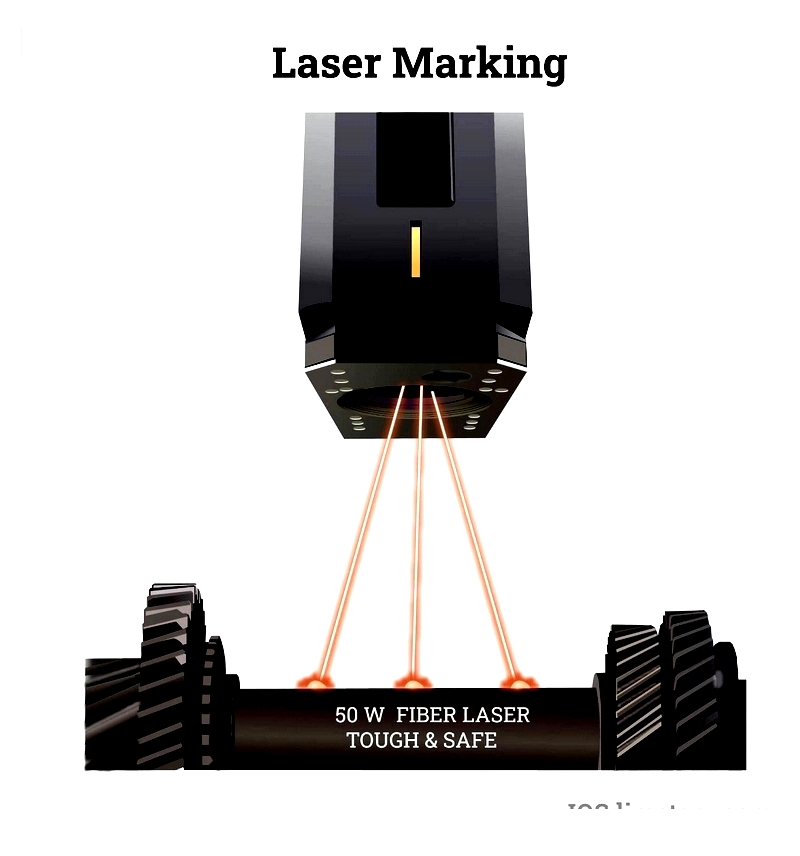

Laser marking applies visible text or codes to component surfaces with minimal penetration, while laser engraving creates deeper impressions beneath the material surface.

A focused light beam produces permanent surface marks using various laser types, including fiber, CO2, pulsed, and continuous wave systems. The process typically involves a laser system with components like an oscillator, scanning mirror, and focusing lens.

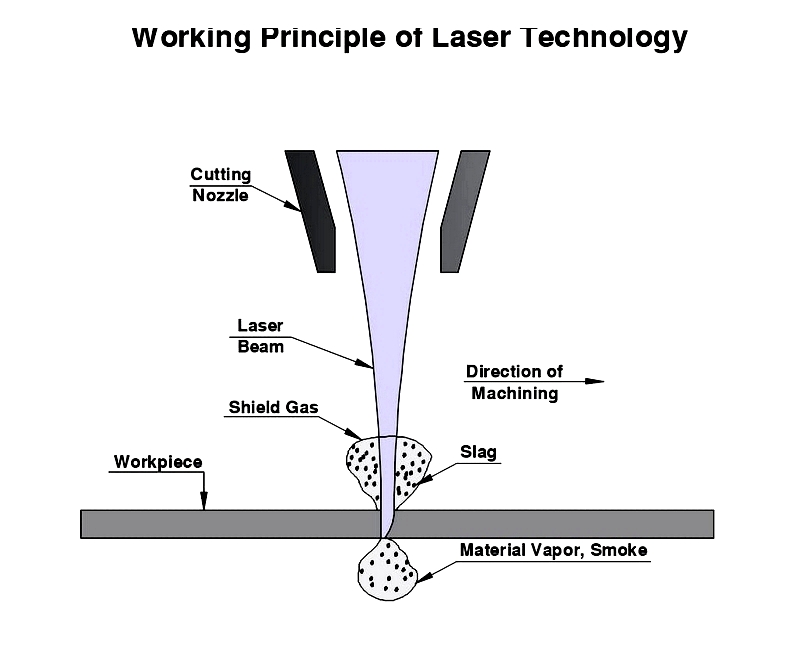

How They Operate

Laser technology uses concentrated high-energy beams to create permanent surface marks. Mirrors direct the coherent beam onto materials, transferring heat energy that alters surface properties. Depending on energy levels, the process can engrave, etch, anneal, or discolor surfaces with precision, producing high-contrast, durable marks ideal for applications requiring accuracy.

Considerations for Selecting Laser Marking and Engraving Machines

- Material type is primary - organic (wood, glass, plastic) or non-organic (metals, steel, aluminum)

- Desired mark appearance - depth, contrast, and technique (dark or frosted marks)

- Safety: Installation location determines necessary precautions. Class I systems require enclosures and warning lights, while Class IV lasers need dedicated rooms with protective measures.

Chapter Two - Materials and Techniques in Laser Marking and Engraving

Materials Used for Laser Engraving and Marking

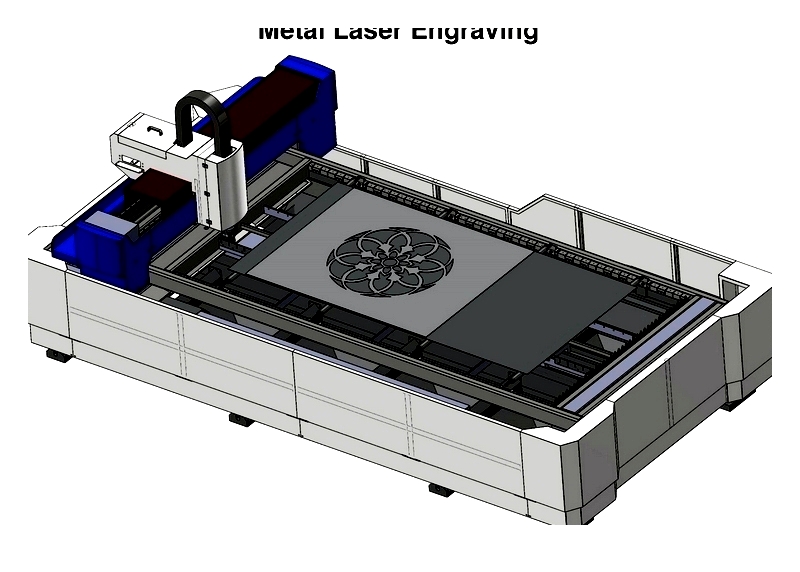

metal

metal laser engraving is widely used in industrial applications for product identification. It effectively marks stainless steel, aluminum, copper, and titanium with serial numbers, barcodes, and logos. The non-contact process meets strict industry standards for durability and precision.

Wood

Wood responds well to laser techniques for artistic and craft applications. Proper power and speed settings prevent damage while creating sharp, permanent marks for signs, awards, and decorative items.

Marble and Granite

These materials produce high-contrast engravings for memorials and signage. Granite's durability makes it suitable for outdoor use, while marble's texture enhances artistic applications.

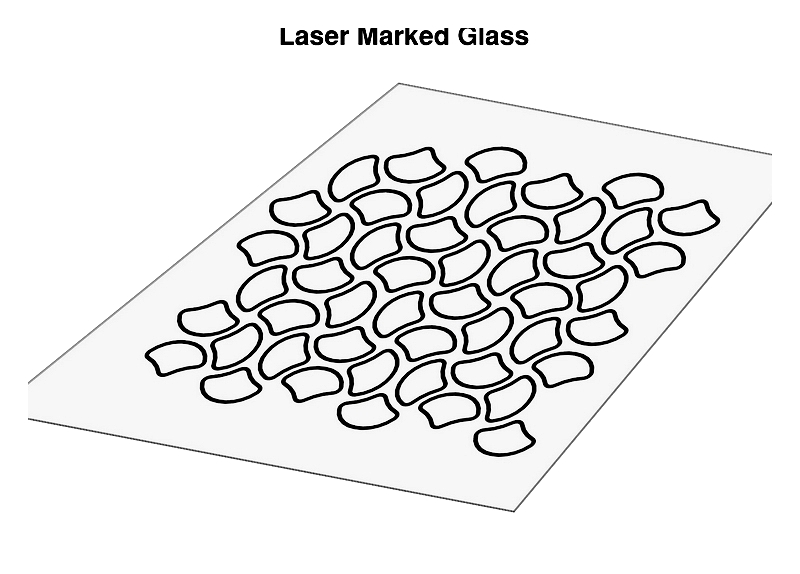

Glass

Laser engraving creates frosted effects on glass items like bottles and trophies. Careful control prevents chipping while achieving crisp, permanent designs.

Fabric

Textiles including cotton and polyester can be precisely marked with intricate patterns. CO2 and fiber lasers provide contactless, eco-friendly solutions for fashion and branding applications.

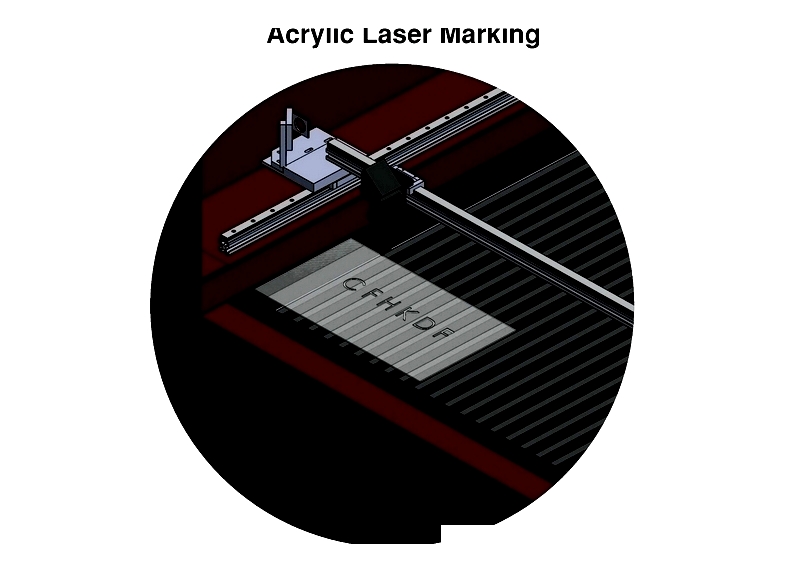

Acrylic

PMMA materials offer excellent engraving results. Cast acrylic produces high-contrast white marks ideal for signage, while extruded acrylic works well for cutting applications.

Bricks and Stones

Laser technology creates durable outdoor markings on these materials, offering advantages over traditional sandblasting methods.

Laser Engraving Techniques

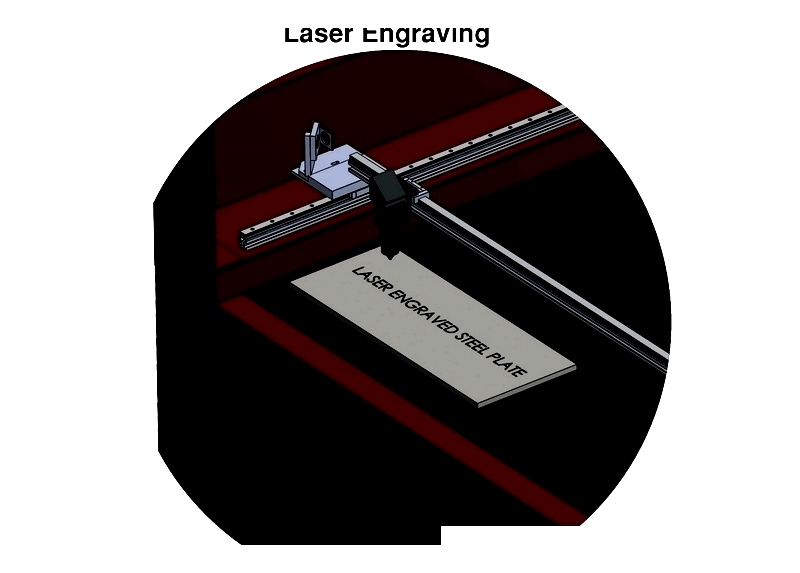

Laser Engraving

This process removes material to create permanent impressions with high precision, suitable for various materials in industrial applications.

Laser Etching

Thermal marking creates raised or shallow marks on metals and plastics, ideal for product identification.

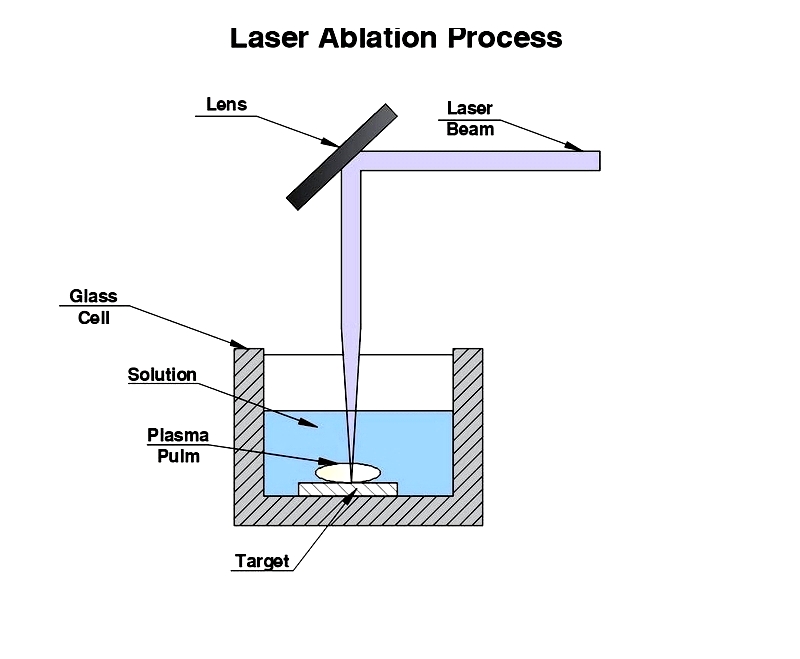

Laser Ablation

This precise method removes coatings without substrate damage, valuable in aerospace and electronics industries.

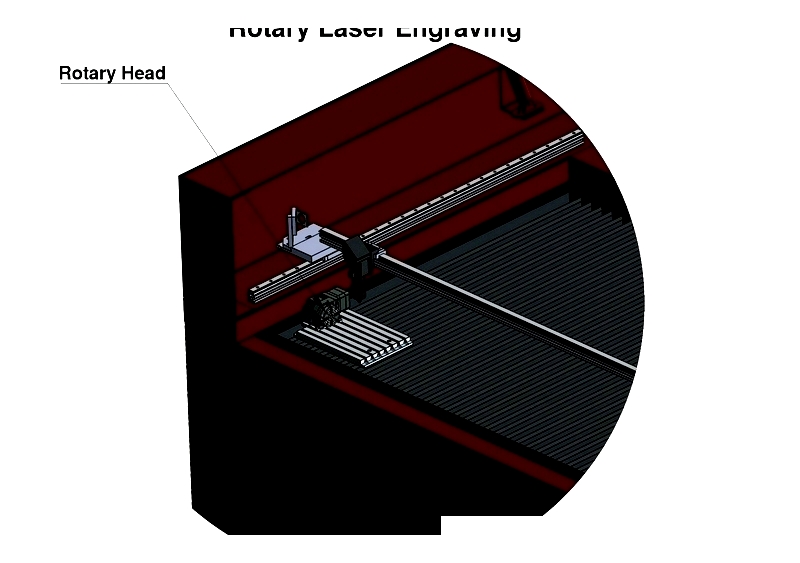

Rotary Laser Engraving

This method creates deep cuts in metal components, suitable for industrial tags and nameplates requiring durable markings.

Diamond-Drag Scratch Engraving

This technique produces fine markings on soft metals, ideal for jewelry and awards with delicate designs.

Laser Marking

Discoloration

This method creates high-contrast marks by removing surface layers, effective for product labeling and branding.

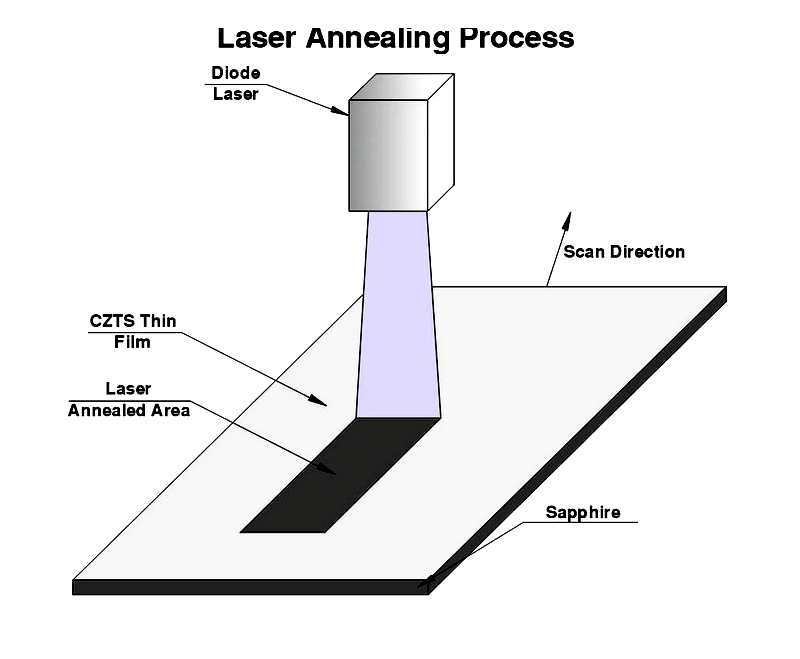

Laser Annealing

Heat-induced color changes create durable marks on metals, particularly valuable for