Introduction

This article provides comprehensive industry insights into plastic materials.

Continue reading to explore topics including:

- What are Plastic Materials?

- Benefits of Plastic Materials

- Raw Plastic Production

- Different Types of Plastics

- Plastic Fabrication Processes

- And much more...

Chapter 1: Understanding Plastic Materials

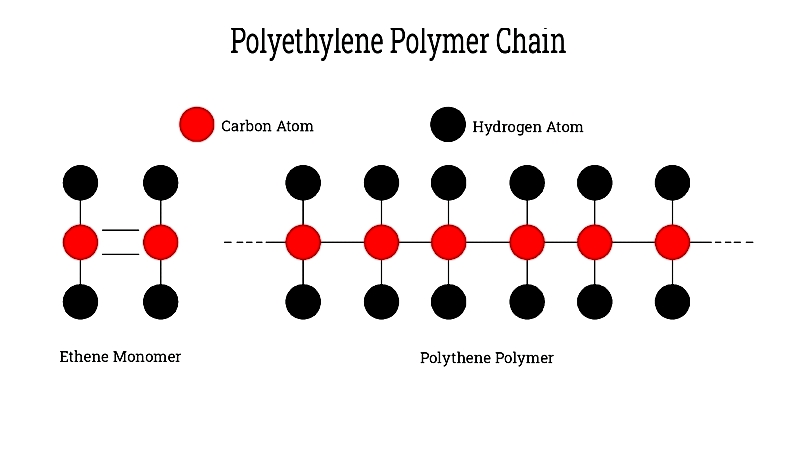

Plastic materials are synthetic substances composed of polymers - long molecular chains primarily made of carbon atoms. These polymers consist of repeating units called monomers, with additional atoms like hydrogen, nitrogen, oxygen, and sulfur in their structure.

Plastics are generally divided into two categories based on their heat response: thermoplastics and thermosets. Thermoplastics can be repeatedly heated and reshaped, making them recyclable. Thermoset plastics, once cured, form rigid cross-linked structures that cannot be softened again, rendering them non-recyclable.

Before plastics emerged during the mid-19th century industrial revolution, people primarily used natural materials like abundant wood. For millennia, basic methods were used to craft metals such as iron and bronze, similar to early glass production techniques.

The advent of plastic revolutionized both everyday and industrial manufacturing. Their moldability, versatility, and durability attracted scientists and inventors seeking to expand potential applications.

Plastic formulations can be customized to exhibit specific properties. Through various chemical processes, characteristics like toughness, resilience, hardness, and heat resistance can be tailored for particular uses.

Exploring the History of Plastics

Originally, "plastic" described materials that were "pliable and easily shaped," referring mainly to polymers meaning "of many parts." Natural polymers like plant cellulose were known long before synthetic versions. The development of synthetic polymers from petroleum allowed creation of longer molecular chains than those found in nature.

In 1856, Alexander Parkes introduced Parkesine, a flexible material made of nitrocellulose, alcohol, camphor, and oil, marking the beginning of the modern plastic industry. His pioneering work inspired further developments by other scientists.

John Wesley Hyatt built on Parkes' work, developing in 1869 a plastic substitute for ivory in billiard balls by treating cellulose nitrate with camphor. Collaborating with Charles Burrough, he created machinery for mass production.

The first fully synthetic plastic, Bakelite, was developed by Leo Baekeland in 1907. This phenol-formaldehyde product became widely used for sealants, lacquers, and molded items due to its successful mass production.

The 20th century saw numerous new plastics emerge, particularly during World War II when production increased dramatically for military applications. Post-war, production shifted to meet consumer demands, growing the plastics industry into a global necessity.

Fish paper, also known as fiber paper or vulcanized fiber, was developed alongside plastics and patented by Thomas Taylor in 1859. Produced by vulcanizing cellulose fibers treated with zinc chloride, acids, or bases, it's available in sheets, rolls, or coils. Its temperature resistance and durability make it ideal for insulation.

Chapter 2: What are the Advantages of Plastics?

Plastics have earned the title of "wonder material" due to their exceptional versatility across manufacturing, construction, packaging, automotive, aerospace, medical, and consumer products. Unlike traditional materials, they offer design flexibility, chemical resistance, and cost-effectiveness, though environmental concerns remain regarding pollution and sustainability.

Key advantages making plastics preferable across industries include:

Formability and Design Flexibility

Plastics can be molded, cast, extruded, or thermoformed into complex shapes, enabling intricate designs that might be costly with metals. Simpler, cheaper molds reduce lead times and costs for custom products and prototypes.

Chemical and Corrosion Resistance

Unlike metals that rust, plastics resist corrosion and chemical attack, making them ideal for pharmaceuticals, food processing, and medical applications where hygienic materials are essential.

Lightweight and High Strength-to-Weight Ratio

With densities much lower than metals, plastics reduce shipping costs and improve fuel efficiency. Advanced engineering thermoplastics can match or surpass metal strength while maintaining manufacturing benefits.

Customizable Properties

From flexible polyethylene to rigid polycarbonate, plastics can be engineered with additives for enhanced flexibility, strength, or fire safety, meeting diverse application requirements.

High Impact and Abrasion Resistance

Plastics' molecular structure provides elasticity and impact absorption, making them shatter-resistant for safety gear, packaging, and toys. Proper formulations enhance tear and abrasion resistance.

Superior Aesthetics

Plastics can be produced in any color or finish directly from molds, eliminating need for expensive secondary processing and enabling brand customization.

Durability

Chemical, water, and wear resistance give plastics long service lives, though this durability presents environmental challenges if not properly managed.

Recyclability

Many thermoplastics can be recycled mechanically or chemically, supporting circular economy initiatives and helping companies meet sustainability goals.

Cost-Effective Production

Lower material and energy requirements make plastic manufacturing more economical than metal or glass production, with processes enabling high-volume, automated production.

Innovative Applications

Plastics drive innovations in biodegradable polymers, bioplastics, and smart materials. Key applications include:

- Medical devices utilizing biocompatible plastics

- Automotive/aerospace using structural composites

- Electronics benefiting from insulating properties