Introduction

This article provides comprehensive information about thermoforming, covering the following topics:

- What is Thermoforming?

- Thick and Thin Gauge Thermoforming

- Thermoforming Process

- Types of Molds

- Thermoforming Methods

- Materials Used in Thermoforming

- Common Problems and Quality Issues in Thermoforming

Chapter 1: Understanding Thermoforming

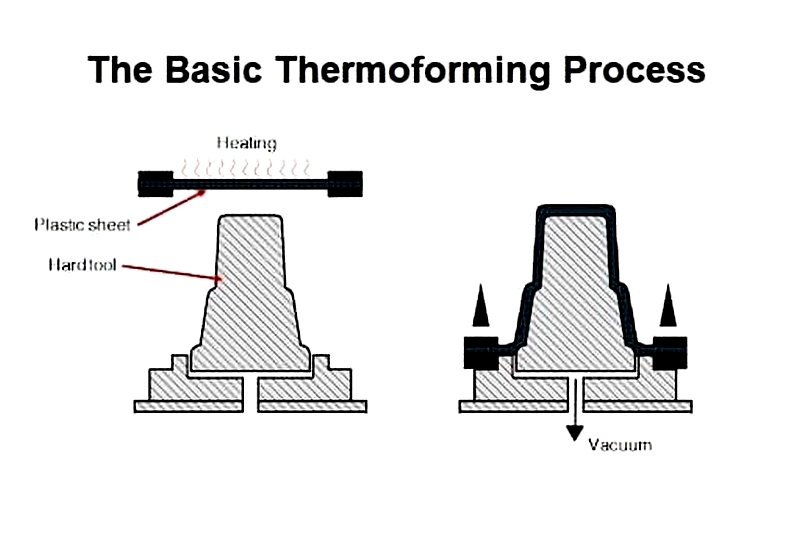

Thermoforming is a plastic fabrication technique that molds thermoplastic sheets into various shapes using pressure or vacuum. This process creates products like cups, containers, lids, trays, and clamshells from thin thermoplastic sheets. Thicker sheets are used for more durable components such as automotive doors, dashboard panels, refrigerator liners, and plastic pallets.

The two primary thermoforming techniques are vacuum forming and pressure forming. Both methods involve stretching heated thermoplastic sheets over a mold's surface, with each offering distinct advantages for different design needs. The selection depends on specific project requirements.

During thermoforming, a plastic sheet is shaped within a mold cavity using air or vacuum pressure. Each cavity is designed to produce a specific part, with the complete mold setup (called "tooling") typically containing multiple cavities.

Thermoforming involves simple steps, making it ideal for high-volume production. The process continuously feeds thermoplastic sheets into a heating chamber for shaping. For larger components, individual thicker sheets are processed separately. Some systems include an extrusion machine before thermoforming, while others enable simultaneous production of multiple parts through multi-cavity molds.

Chapter 2: Differences Between Thick (Heavy) Gauge and Thin Gauge Thermoforming

The thickness of thermoplastic sheets significantly influences the thermoforming process, affecting techniques, equipment, and final product performance. Understanding material properties helps achieve optimal quality, cost-efficiency, production speed, and reliability. Proper gauge selection ensures compliance with industry standards across various applications.

Thick Gauge or Heavy-Gauge Thermoforming

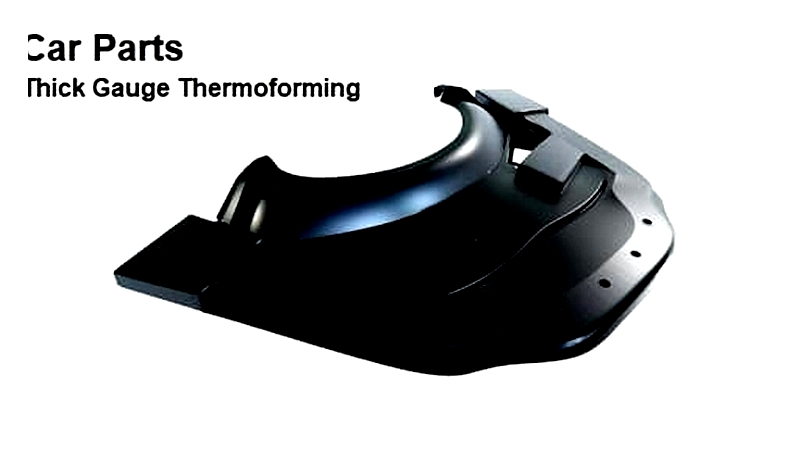

Heavy-gauge thermoforming uses plastic sheets ranging from 0.060" to 0.500" (1.5–12.7 mm) thick. The process begins with precise cutting of rigid plastic sheets, followed by uniform heating before mold forming. This method produces large, durable components like automotive panels, equipment housings, and industrial trays.

Thick gauge thermoplastics offer superior mechanical performance, including impact resistance and structural integrity. They allow for complex geometries with smooth surfaces and can be modified for UV resistance, flame retardancy, or chemical resistance. These materials are often FDA-approved for medical and food applications and provide weight savings compared to metal alternatives.

Thin Gauge Thermoforming

Thin gauge thermoforming produces lightweight products using sheets under 0.060" (1.5 mm) thick. The process feeds large thermoplastic rolls into high-speed machines, creating flexible packaging for food, pharmaceuticals, and retail applications.

This method enables mass production of items like blister packaging, food containers, and medical trays. It offers high speed, low cost, and excellent clarity. Common materials include FDA-approved PP, PS, PET, PVC, and HDPE, chosen for their safety and recyclability.

Selecting between thick and thin gauge thermoforming requires considering project volume, customization needs, performance requirements, and regulations. Consulting with experienced manufacturers ensures optimal results from design through production.