Introduction

This article provides all the essential information about die cutting. Continue reading to learn more about:

- The history of die cutting

- Different types of die cutting machines

- Capabilities of die cutting machines

- Design considerations for die-cut parts

- And much more…

Chapter 1: What is Die Cutting?

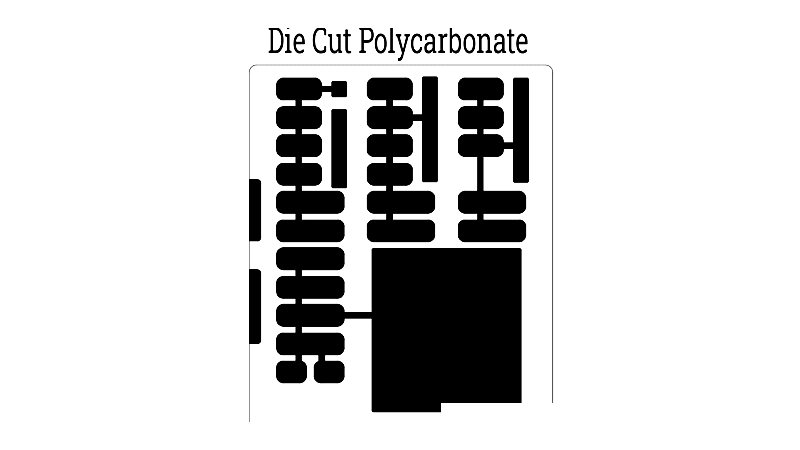

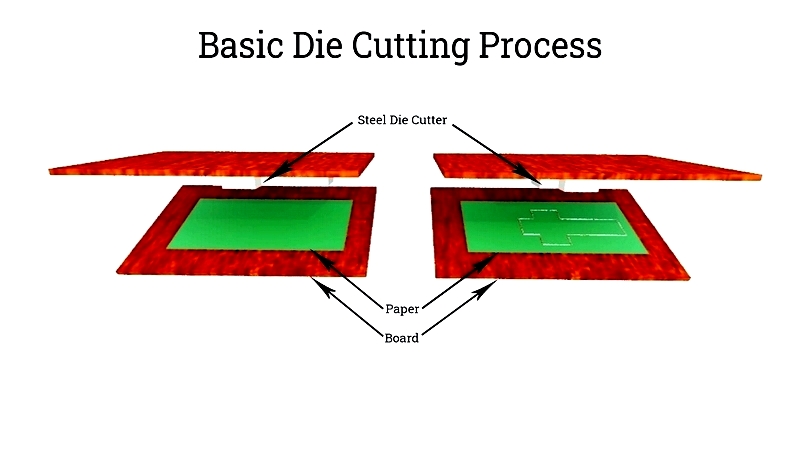

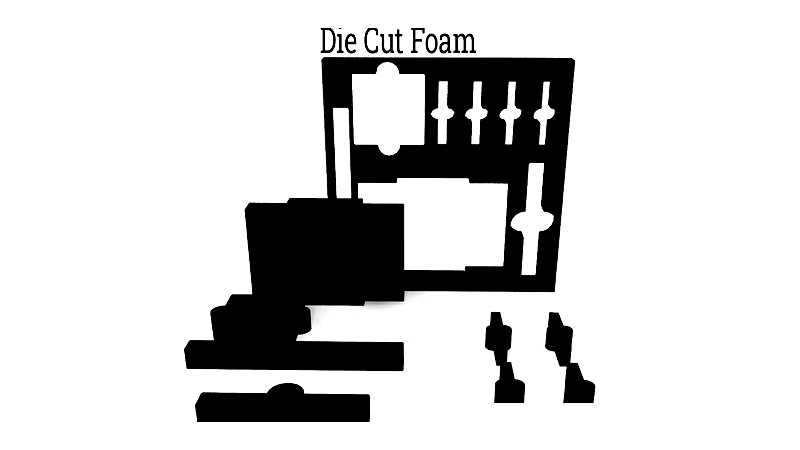

Die cutting is a mass production technique that uses custom-made dies to cut materials like paper and chipboard into specific shapes. A die is a specialized tool with sharp edges designed to create precise two-dimensional shapes, similar to how a cookie cutter shapes dough. This process works with various materials, including paper, fabrics, rubber, fiberglass, metal sheets, foam, wood, and plastics.

Die cutting originated during the first industrial revolution, revolutionizing shoe manufacturing. Before its invention, shoemakers manually cut soles, limiting production capacity. Die cutting introduced templates that standardized and accelerated sole production. Over time, this method has transformed multiple industries and continues to evolve for more complex designs.

Today, die cutting incorporates advanced technology, using computer-aided design (CAD) with CNC machines for automated and semi-automated operations. It's widely used in packaging, consumer goods, automotive components, DIY projects, and office applications.

Die cutting offers speed and efficiency, with performance depending on stroke speed, material feeding method, and machine type. It typically outperforms waterjet cutting and some blade methods. Despite initial costs, its efficiency, speed, and high-quality results make it cost-effective.

This straightforward process suits both low and high-volume manufacturing. In industrial settings, die cutting machines can process materials from previous operations, performing additional tasks like forming, perforating, and scoring with single or multiple press strokes.

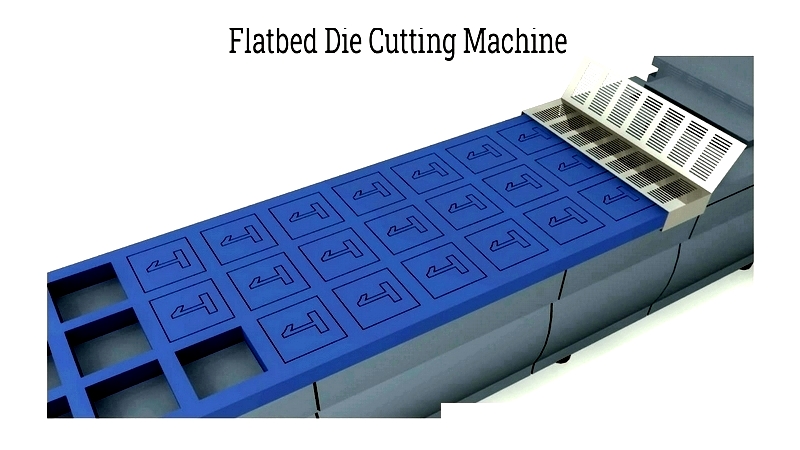

Industrial die cutting machines, including flatbed, rotary, and semi-rotary models, handle thicker, durable substrates with fast output rates. Manual and digital die cutting devices are better for simpler components and accessories, with slower speeds ideal for small batch orders.

Chapter 2: What is flatbed die cutting?

Flatbed die cutting is a precise, versatile manufacturing process used across industries to convert raw materials into custom shapes. This die cutting process works for both low-volume and high-volume production, making it popular in packaging, automotive, medical device manufacturing, gasket fabrication, and electronics. It uses heavy-duty flatbed presses and custom steel rule dies to cut, crease, perforate, emboss, or score materials like paper, cardboard, plastics, foams, rubber, and composites.

In industrial settings, die cutting machines can process materials from previous operations like laminating, printing, or slitting. This flexibility allows the machine to perform additional tasks like forming, perforating, slitting, kiss cutting, and scoring, making flatbed die cutting highly adaptable for precision components.

Industrial die cutting machines, including flatbed die cutters, rotary die cutters, and semi-rotary systems, handle thicker, rigid substrates like plastics and heavy-duty foams with high repeatability and fast production rates. Manual die cutters and digital die cutting equipment are better for simpler parts or prototypes, with slower speeds suited for short-run and custom orders. Manufacturers choose between these die cutting technologies based on industry needs and tolerances.

Feeding

The feeder mechanism transports material from the feed tray or roll to the cutting area using suction, pushing, or pulling systems. Automated feeders regulate feed rate and positioning, ensuring registration accuracy for precise cuts, especially for intricate shapes. Proper feeding minimizes waste and prevents errors, improving production efficiency.

Cutting

The cutting assembly includes a die board paired with a lower counter plate for precise cuts. The die board holds sharp steel rule blades to cut the material into finished parts. It resists warping under pressure, ensuring accurate, repeatable cuts. Custom tools and optional features like embossing or perforating define the geometry and surface characteristics of the final product.

Steel rule

The steel rule die is a precision metal strip shaped to the desired outline. When pressed against the material, it delivers full or partial cuts:

- Full cutting—Cuts completely through the material.

- Partial cutting (kiss cutting)—Cuts partially through the material, often leaving an adhesive backing for labels or gaskets.

For thicker materials like dense foam, pressing force may cause slight concavity. Lamination or multi-step die cutting can achieve the required thickness and stability.

Punches

Punches create precise internal cut-outs in standard or custom shapes. Self-ejecting punches remove waste quickly, preventing jams.

Rubber ejection strip

Rubber ejection strips help remove finished parts from the die by providing gentle opposing force, minimizing adhesion or jamming. This improves throughput and protects delicate materials.

The lower counter plate supports the material during cutting. Precision alignment between the die board and counter plate ensures clean edges and uniform quality.

Simple Die

A simple die makes one cut per press stroke, ideal for low-complexity shapes or prototypes.

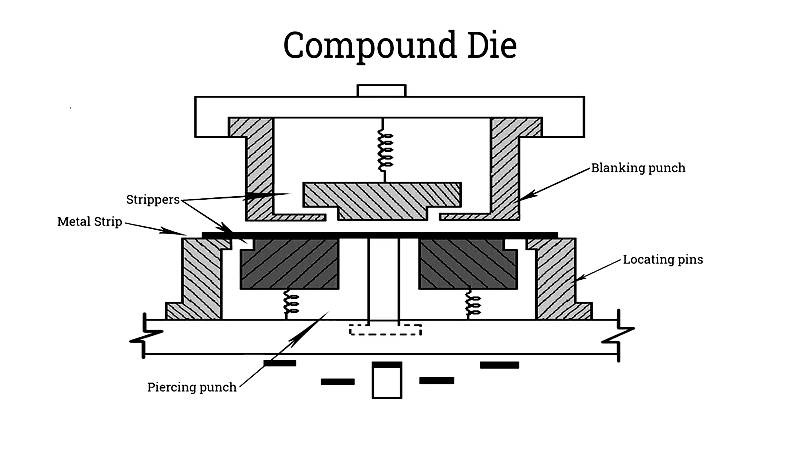

Compound Die

A compound die performs multiple cuts in one operation, improving efficiency. For example, it can cut the outer perimeter and inner hole of a washer in one stroke. These dies combine steel rule sections with machined components for clean edges, reducing secondary finishing.

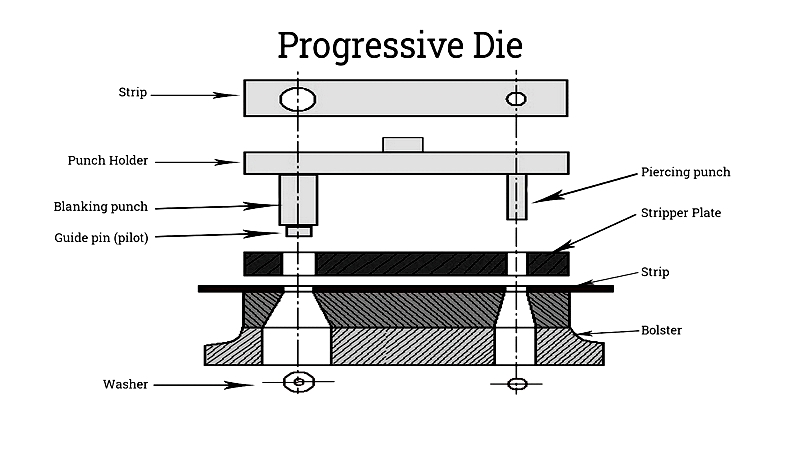

Progressive Die

Progressive die cutting handles complex parts requiring multiple operations like cutting, notching, or embossing. The material advances through stations with each press cycle, maintaining registration accuracy for high-volume production. This method is common in automotive and electronics manufacturing.

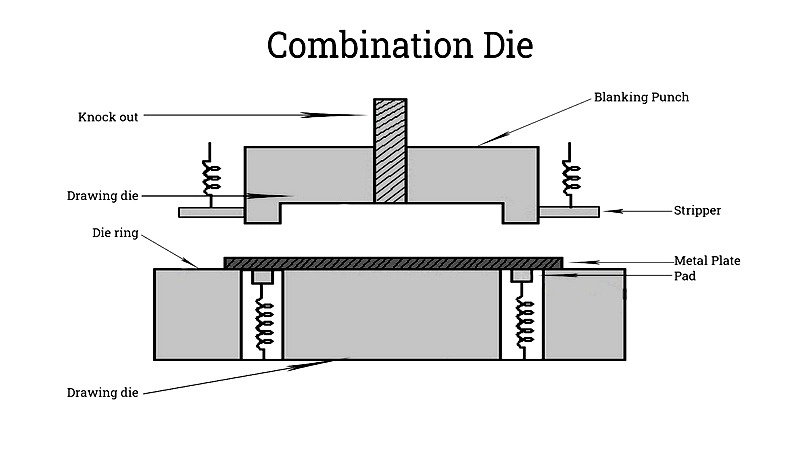

Combination Die

Combination dies perform cutting and forming operations like bending or embossing in one stroke. They streamline production for parts with complex features and tight tolerances.

Selecting the right die type, material, thickness, and pressure settings is crucial. Heavier materials require robust dies and higher tonnage. Material selection and press capacity should align with desired features for optimal quality.

Stripping

After cutting, stripping