Introduction

This article provides an in-depth examination of high strength ropes.

It covers various topics including:

- What are High Strength Ropes?

- Materials Used in High Strength Ropes

- Types of High Strength Ropes

- Fiber Varieties

- And More...

Chapter 1: What are High Strength Ropes?

High strength ropes consist of strands, fibers, piles, and yarn joined together to form a robust structure. These components are either twisted or braided to create ropes with high tensile strength that are durable and resilient. Used for lifting and dragging, ropes have served humanity since prehistoric times for purposes like hunting, climbing, securing items, and transportation. Originally made from natural fibers, synthetic fibers began being used in rope production during the 1950s. There are two main categories of high strength ropes: natural and synthetic.

Natural Ropes

Natural ropes are made from eco-friendly materials that don't produce harmful byproducts during manufacturing. Common materials include cotton, hemp, and sisal. When blended with synthetic fibers, these ropes become stronger and more durable. While robust, natural fiber ropes can be damaged by water, mildew, mold, or UV exposure. They resist high heat but may burn in open flames. These ropes may shrink when wet and not regain their original form, limiting some applications. However, their non-slip properties make them excellent for securing objects.

Synthetic Fiber Ropes

Synthetic fiber ropes are manufactured from materials like nylon, polyester, and polypropylene. These ropes are stronger and last approximately 30% longer than natural fiber ropes. They resist damage from wet conditions, mildew, UV light, and mold, making them suitable for outdoor use. However, they perform poorly under heat exposure as they may melt. While not environmentally friendly due to production byproducts, their strength makes them ideal for lifting and towing applications.

Construction of High Strength Ropes

High strength ropes come in various constructions defined by their twisting or braiding patterns. Each type is categorized and named based on its specific manufacturing method, as detailed below:

Single Braid 12 Strand Rope

Made from HMPE with an excellent strength-to-weight ratio, single braid 12 strand ropes surpass wire rope in break strength. Their interlocking braid construction provides exceptional strength for heavy lifting or pulling. The braiding process uses twelve HMPE fiber strands woven in an over-and-under pattern. For optimal performance and protection, these ropes are often coated with an elastomer jacket.

Plaited Rope

Also called square braid rope, this coarser variety consists of four twisted strand sets interwoven into a braided structure. Highly flexible and strong, these ropes knot easily but have all strands exposed to environmental damage due to their twisted core design.

Twisted Rope

Commonly known as laid rope, twisted rope is ideal for splicing applications. Constructed by twisting strands in one direction, then combining three such strands in the opposite direction, it offers good grip strength but may kink if mishandled. Frequently used for dock lines and towing operations.

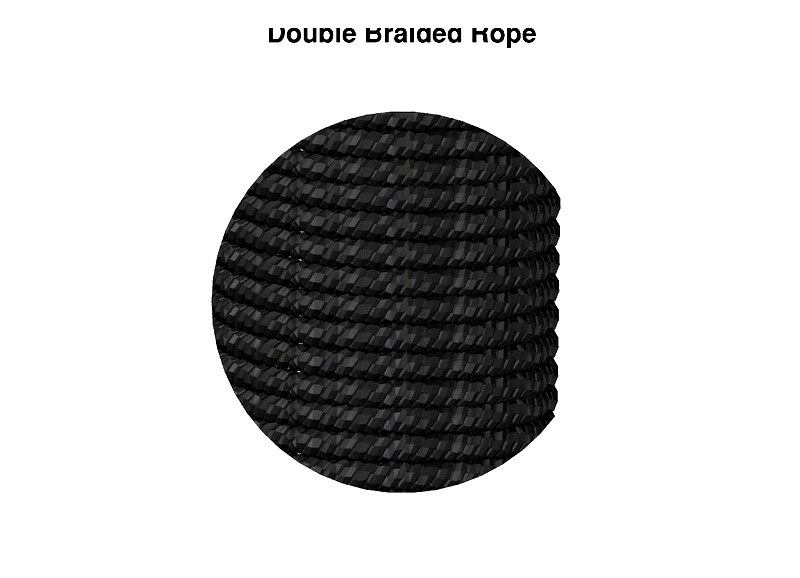

Double Braided Rope

This type offers exceptional strength and durability, featuring double-braided strands coiled around a core for enhanced stability. Highly abrasion-resistant, it performs well in marine environments but less so in manufacturing settings. Its construction prevents kinking while providing substantial strength.

Hollow Ropes

Lightweight synthetic ropes with a hollow core, these are easily spliced and water-resistant, making them suitable for ski towing and anchor lines.

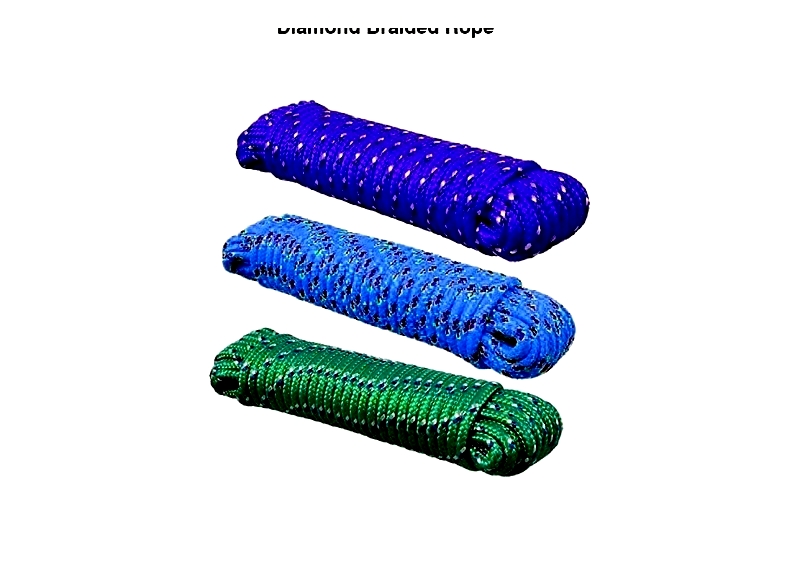

Diamond-Braid Rope

Created by tightly braiding fibers around a core, these ropes offer a firm, rigid structure. Though more expensive, their precise braiding delivers durability, roundness, and easy splicing capability with other rope types.

Jacketed Rope

Featuring a protective synthetic coating (urethane or TPE), jacketed ropes resist abrasion and UV damage. The colored jacket serves as both protection and identification. Particularly valuable for outdoor use, this covering significantly slows fiber degradation from environmental exposure.