Introduction

This article provides an in-depth exploration of carrying cases.

You will learn about topics including:

- The uses of carrying cases

- Different types of carrying cases

- How carrying cases are manufactured

What Are the Uses of Carrying Cases?

Since ancient times, beginning with the Egyptians and earlier civilizations, people have created cases to transport valuable items. Carrying cases are everywhere - in homes, garages, basements, and on shelves. These versatile containers serve various transportation needs. In today's digital age with laptops and tablets, carrying cases are particularly common, especially in educational environments. While they're frequently encountered, defining them precisely remains challenging.

During Roman times, the aristocracy refined the concept of carrying cases by employing dedicated bearers to protect their valuables. These specialized servants had dual responsibilities: they handled items with care and protected them from theft. While it's unclear whether these carriers were carefully selected or chosen at random, such positions were probably considered prestigious.

Modern depictions, like those in Disney's Toy Story 2, show how the concept of specialized care for carrying cases has endured. Today, valuable shipments can be insured against loss or damage. Scientific instruments, precious antiques, and important family or business items are placed in custom-designed cases for protection during transport. Although we no longer have personal servants to carry valuables, modern protective solutions effectively serve the same purpose.

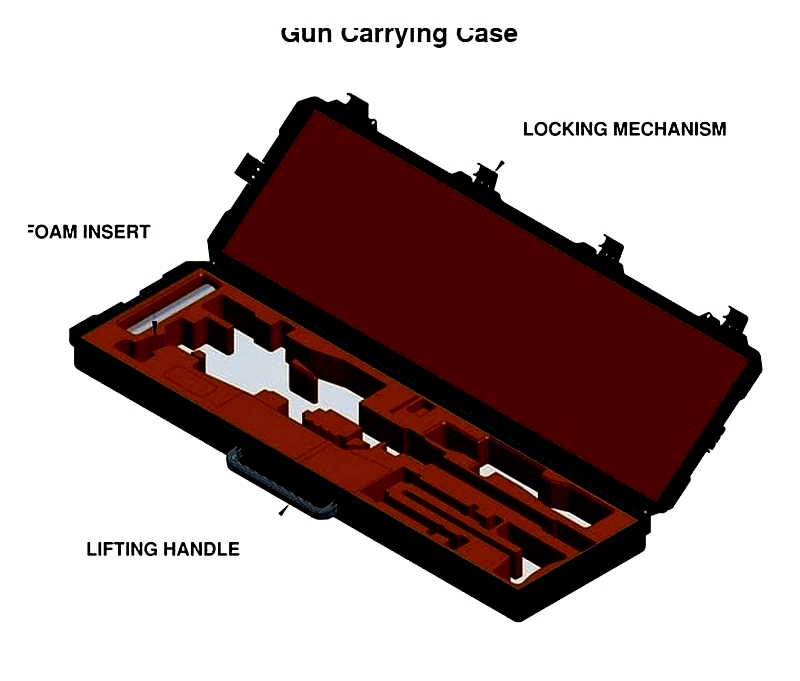

People interpret carrying cases differently based on their needs. Firearm enthusiasts, for instance, use specialized portable cases to safely store and transport guns, rifles, or revolvers. These cases must meet specific standards to accommodate different firearm types. A contemporary example is the specially designed case for samurai swords, which requires particular attention to protect the blade.

Generally, carrying cases are defined by their protective function. When choosing a case, the crucial consideration is its ability to withstand environmental factors and safeguard contents. Whether designed for clothing or musical instruments, each case must meet its user's specific requirements. The meaning of a carrying case varies across users - from construction workers and athletes to executives and professionals - with each application demanding tailored solutions.