Introduction

This article provides comprehensive information about Coriolis Flow Meters. You'll explore key topics including:

- What is a Coriolis Flow Meter?

- How Coriolis Flow Meters work

- Different types of Coriolis Flow Meters

- Installation of Coriolis Flow Meters

- And more...

Chapter One – What is a Coriolis Flow Meter?

Coriolis flow meters measure mass flow by utilizing the inertia of fluids or gases moving through vibrating tubes. Sensors at the meter's entry and exit points detect oscillations caused by the flow. These oscillation changes directly correlate with the mass of material passing through. This innovative design makes Coriolis flow meters highly reliable for measuring both liquids and gases.

These meters are widely used across industries handling liquid, gas, or fluid flows. Their advanced technology provides precise measurements of mass flow rates, along with fluid density, viscosity, and temperature.

Chapter Two – How Coriolis Flow Meters Work

Understanding Coriolis flow meters requires knowledge of the Coriolis principle, first described by Gaspard-Gustave de Coriolis in 1835. This principle explains how moving objects experience lateral drift due to Earth's rotation. Similarly, in Coriolis flow meters, fluid movement through specially designed tubes creates twisting motions that are measured to determine flow rates.

This technology enables precise measurement of mass, density, and temperature across various industrial applications.

Operating Principle and Design

Coriolis flow meters excel in measuring challenging substances like process liquids, slurries, and gases. Unlike volumetric meters, they provide direct mass flow measurements unaffected by fluid properties, making them ideal for critical applications requiring precise data.

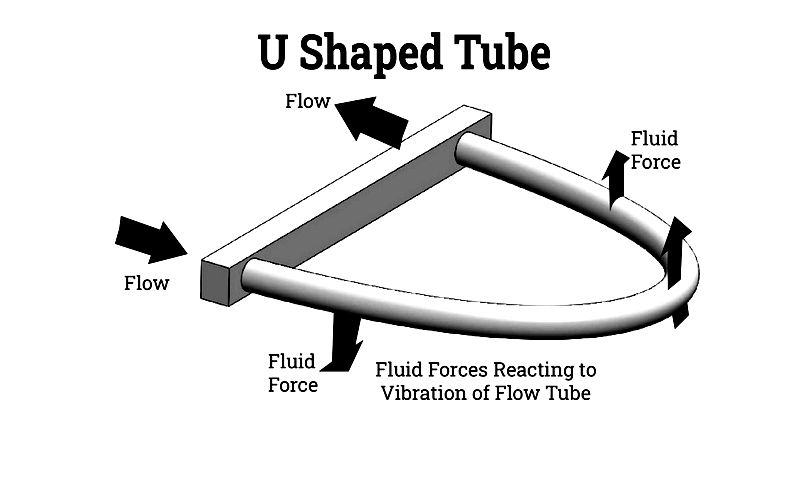

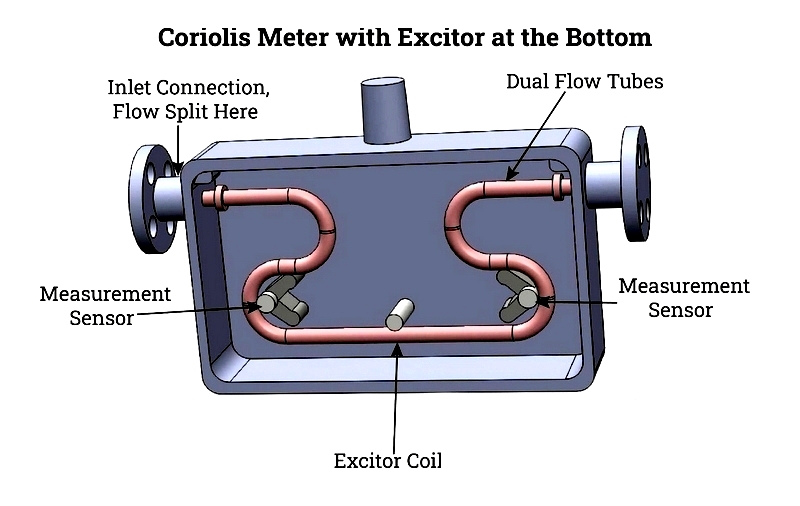

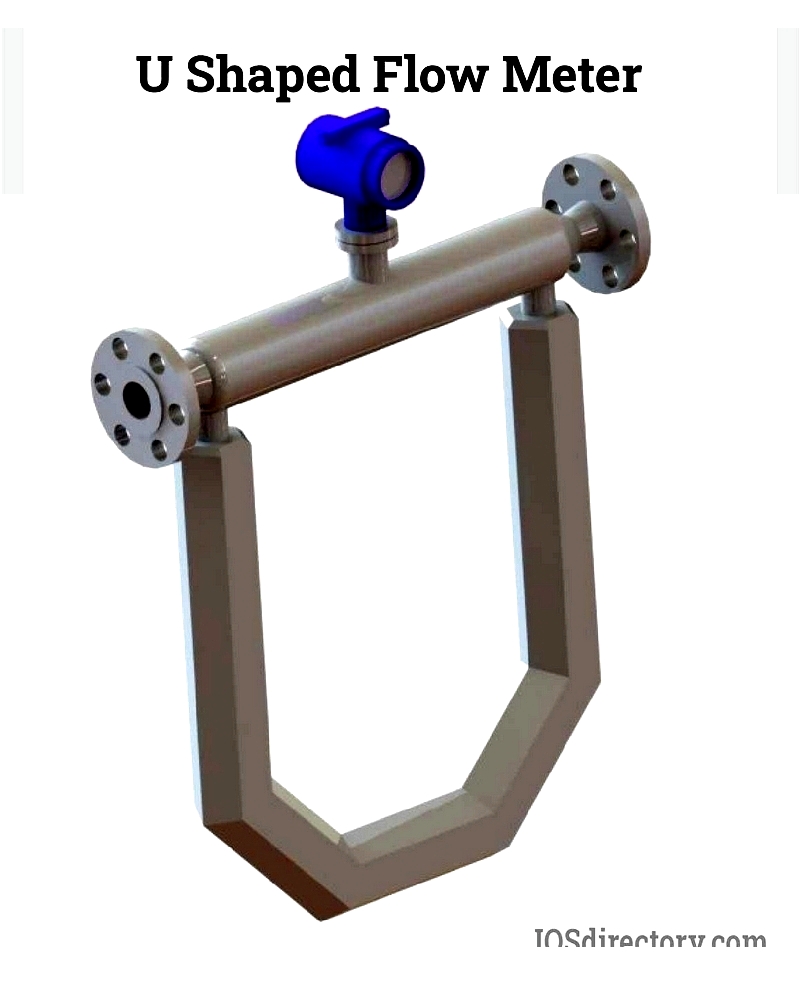

Tube Design

The U-shaped measuring tube is central to operation. Fluid flow causes controlled vibrations that create measurable deformations, detected by sensors for accurate readings.

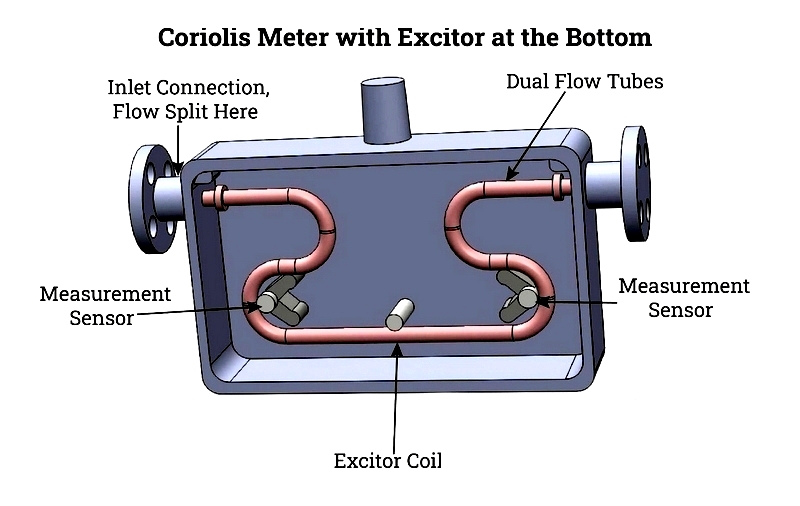

Exciter Mechanism

The exciter maintains tube oscillations essential for measurement. Positioned between sensors, it ensures accurate detection of flow-induced changes.

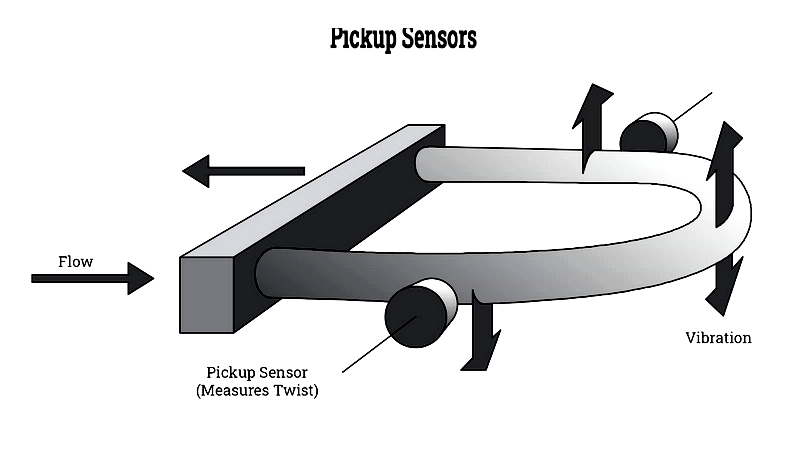

Sensors

Electrodynamic sensors monitor tube motion, detecting phase shifts that indicate flow rate. This system provides measurements independent of fluid properties.

Measurement Process

The phase shift directly correlates with mass flow, ensuring accuracy across varying conditions. Advanced meters also measure density and temperature for comprehensive data.

Controller

The digital controller processes sensor data into readable outputs for mass flow, volume flow, and density. These meters offer flexibility for diverse industrial applications.

Coriolis flow meters provide reliable, accurate measurements for various industrial processes, from chemical transfer to food production.

Chapter Three – Types of Coriolis Flow Meters

Coriolis flow meters are categorized by tube design, each suited for specific applications. Advancements have improved their performance with challenging fluids.

Common Variants

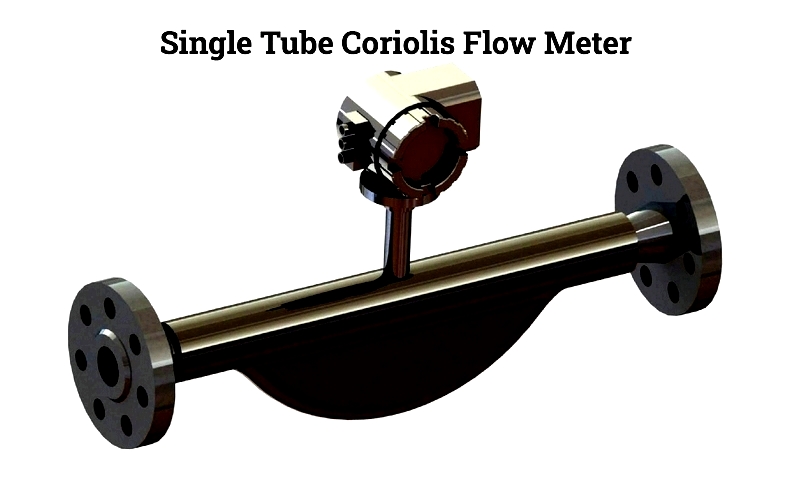

Single Tube

Ideal for high-velocity flows, these meters minimize pressure drop and are easy to clean, making them suitable for chemical and food industries.

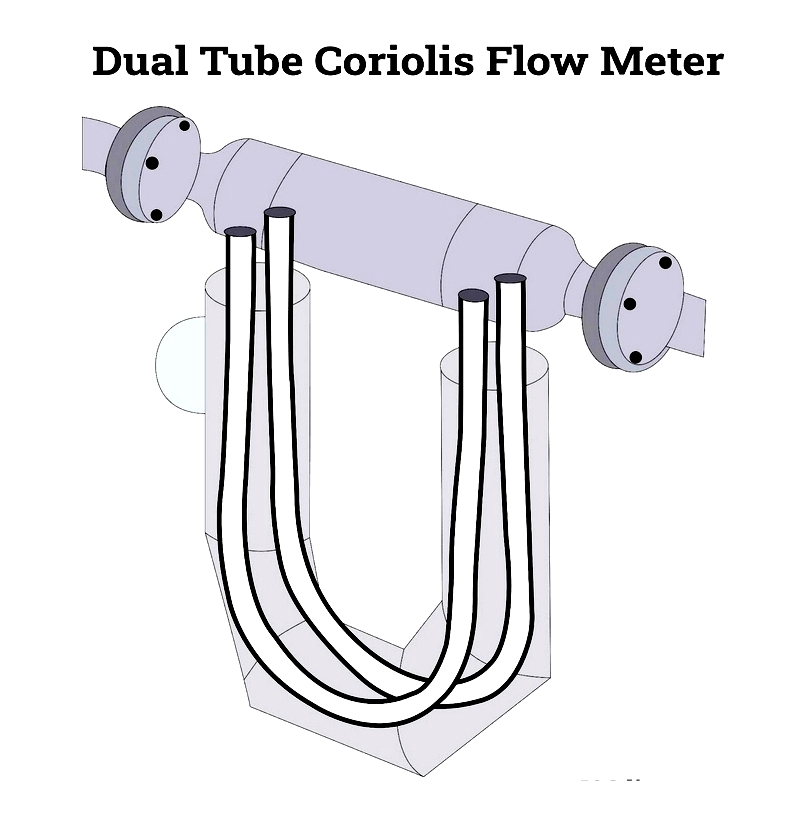

Dual Tube

With parallel U-shaped tubes, these meters resist external vibrations, perfect for precision applications in oil and gas.

Continuous Loop

Their uninterrupted design handles viscous or particle-laden fluids well, reducing maintenance in wastewater and food processing.

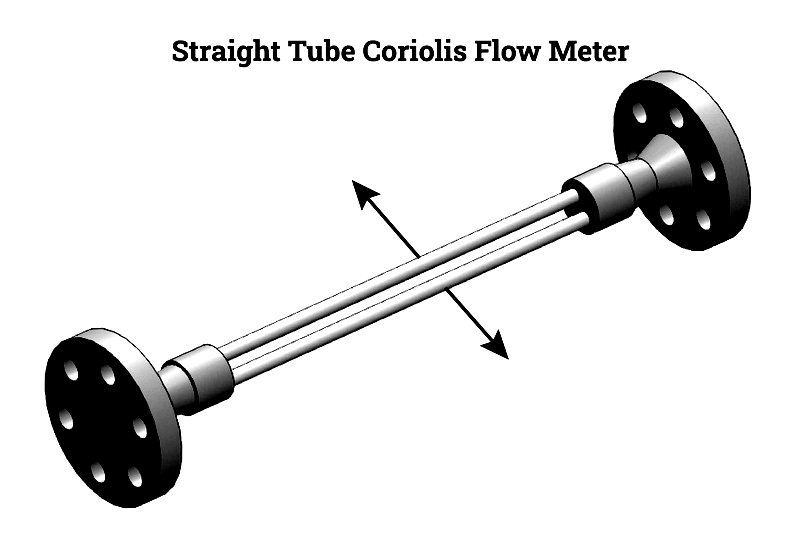

Straight Tube

Preferred in sanitary applications, these meters offer easy cleaning and minimal contamination risk.

U-Shaped

This classic design provides robust measurements for both liquids and gases in various industrial settings.

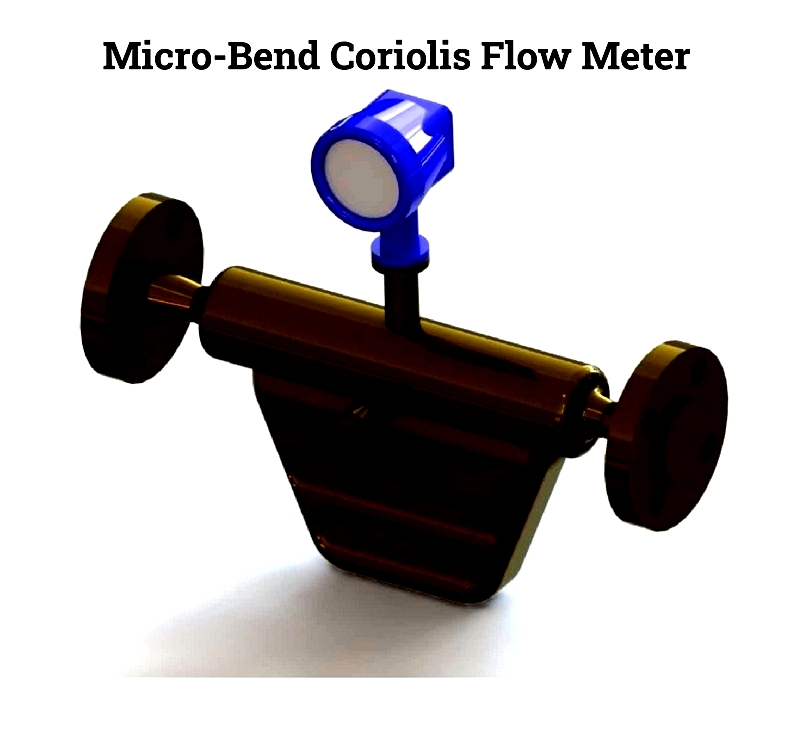

Micro-Bend

Compact and efficient, these meters suit space-constrained installations like process skids and laboratories.

Triangle-Shaped

Ultra-compact design excels in low-flow applications requiring high precision.

Selection Guide

Choose based on fluid type, flow range, installation requirements, and accuracy needs. Consider tube design and special features for optimal performance in your specific application.