Introduction

This article provides an in-depth exploration of air pollution control equipment.

You will discover:

- The definition of Air Pollution Control Equipment

- The evolution of Air Control Equipment

- Different categories of Air Pollution Control Equipment

- Practical uses of Air Pollution Control Equipment

- Maintenance guidelines for Air Pollution Control Equipment

- Strategies for preventing air pollution

- A real-world case study

- Additional valuable information

Chapter 1: Understanding Air Pollution Control Equipment: Functionality and Selection Criteria

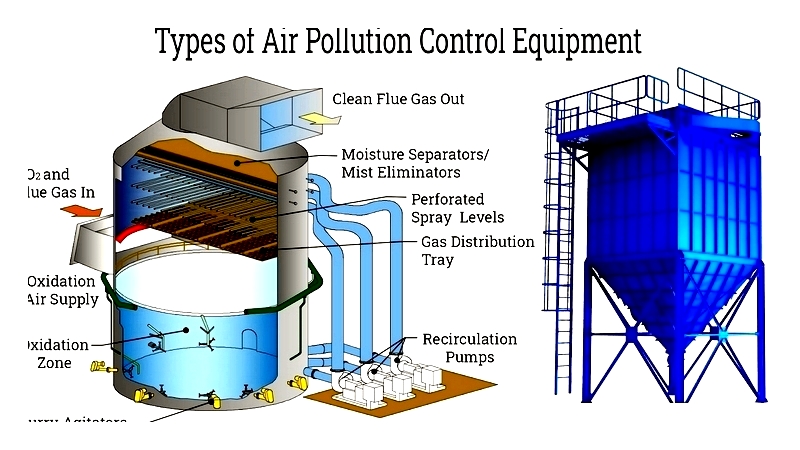

Air pollution control equipment refers to sophisticated systems designed to reduce the release of solid and gaseous pollutants into the atmosphere, primarily from industrial emissions through exhaust stacks or chimneys. These systems fall into two principal categories: those addressing acidic gas emissions and those handling particulate matter emissions.

How Air Pollution Control Equipment Works

Air pollution control technologies operate through three fundamental mechanisms:

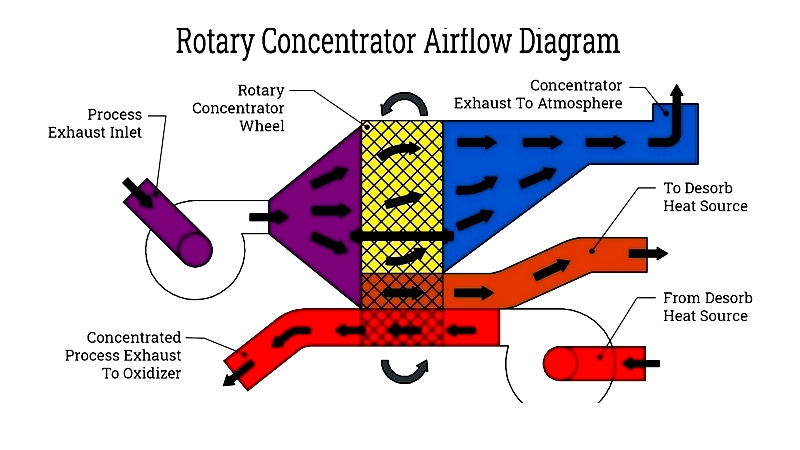

- Chemical Transformation: This process converts harmful chemicals into inert forms. Flue gas desulfurization is a common example. Techniques like selective catalytic reduction and non-catalytic reduction manage nitrogen oxide (NOx) emissions by converting them into nitrogen gas (N2). Professionals may also use biofiltration, thermal oxidation, or catalytic oxidation methods.

- Contaminant Removal: The most prevalent and straightforward approach involves extracting hazardous substances from air. While various methods exist, air filtration systems are commonly employed for this purpose.

Monitoring Air Pollution Control Equipment

Since operational conditions vary significantly across facilities, selecting appropriate monitoring equipment requires more than just comparing performance metrics and costs. Each installation has unique monitoring requirements influenced by several key factors.

Key Factors for Choosing Air Pollution Control Equipment

- Analyze the physical and chemical characteristics of pollutants and waste gas streams before purchasing.

- Verify equipment compatibility with existing systems, considering regulatory constraints and reporting requirements.

- evaluate sampling collection, processing, and management methods as they impact equipment selection.

- Ensure equipment meets calibration and accuracy standards.

- Prioritize quality control when selecting monitoring tools.

- Confirm availability of maintenance services, as all equipment requires regular upkeep.

- Ensure monitoring systems don't compromise existing safety and management protocols.

These considerations help identify the most suitable monitoring equipment for specific operational needs.

Chapter 2: The Historical Development of Air Pollution Equipment

The Industrial Revolution transformed manufacturing but also caused a dramatic increase in air pollution from fossil fuel combustion. As industries expanded, excessive resource exploitation led to heightened emissions of harmful pollutants like sulfur dioxide (SO2), nitrogen oxides (NOx), carbon monoxide (CO), and particulate matter (PM).

By the mid-20th century, the severe health and environmental consequences of industrial pollution became undeniable. Notable incidents included the 1948 Donora smog that killed 20 people, the 1952 London Great Smog claiming 12,000 lives, and the 1984 Bhopal gas tragedy affecting hundreds of thousands.

These disasters, combined with growing scientific evidence linking pollution to respiratory and cardiovascular diseases, prompted global environmental legislation. The UK introduced the Clean Air Act in 1956, while the US followed with the 1970 Clean Air Act, establishing strict air quality standards.

Industries responded by adopting advanced pollution control technologies like baghouse collectors, electrostatic precipitators, and scrubbers to capture airborne contaminants. The electrostatic precipitator, first conceptualized in 1824 and patented in 1907, became particularly influential for particulate removal.

The 1990 Clean Air Act Amendments enhanced regulatory oversight, requiring continuous emissions monitoring. Modern facilities now rely on sophisticated monitoring systems for compliance and operational optimization.

While significant progress has been made in reducing harmful emissions, contemporary regulations increasingly focus on carbon footprints and sustainable solutions. Today's pollution control landscape features advanced technologies like regenerative thermal oxidizers and hybrid systems that combine multiple filtration methods.

Understanding this technological evolution helps ensure regulatory compliance while protecting worker health, communities, and the environment for future generations.