Introduction

This article provides an in-depth exploration of steel channels.

It covers detailed information on various topics including:

- Principles of Steel Channels

- Roll Forming Process of Steel Channels

- Different Types of Steel Channels

- Applications and Benefits of Steel Channels

- And more...

Chapter 1: Principles of Steel Channels

This chapter explores the fundamental concepts of steel channels, detailing their manufacturing process and explaining why steel is the preferred material for these structural components.

What are Steel Channels?

Steel channels are hot-rolled carbon steel sections shaped like a "C," featuring a vertical web with rounded corners at the top and bottom flanges. Each channel consists of a wide web and two flanges, which may be parallel or tapered. The strength and durability of steel make it an excellent choice for producing these metal channels.

Renowned for their structural integrity, steel channels are essential for building frames, braces, and supports for heavy machinery and equipment. In construction, they help reduce noise by being placed between plasterboard walls, effectively dampening sound waves and minimizing vibrations. Steel channels are valued for their ruggedness and longevity, making them suitable for various demanding applications.

Manufacturing Process of Steel Channels

Steel channels are produced from hot-rolled mild steel, with precisely radiused interior corners to ensure strength and rigidity for supporting steel angles in various building contexts. With the right equipment and specifications, steel channels can be manufactured efficiently, typically conforming to ASTM A36 dimensional standards.

After hot rolling, steel channels often undergo additional inline fabrication. They are commonly coated or galvanized to enhance corrosion resistance. These channels can be accurately cut, drilled, or machined to meet specific requirements and are easily welded. Larger channels are frequently produced using laser fusion technology.

Why Steel is Ideal for Channels

Steel is the preferred material for metal channels due to its exceptional mechanical properties.

- Hardness: This property refers to a material's resistance to surface indentation and scratches. Hardness is valued in engineering for its ability to increase resistance to wear, friction, and erosion caused by elements like steam, oil, and water.

- Toughness: Toughness describes a material's ability to absorb energy without fracturing. Unlike hardness, a highly deformable material that doesn't break easily can be extremely tough without necessarily being hard.

Chapter 2: Roll Forming of Steel Channels

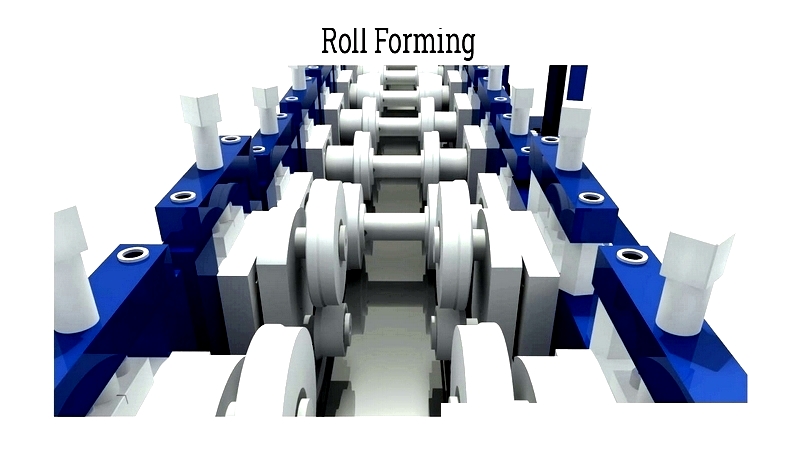

Roll forming transforms metal sheets or strips into high-strength, durable steel channels, widely used in construction, infrastructure, and manufacturing. This precision metal fabrication process involves continuously bending flat, coiled metal strips through a series of rollers, each acting as a forming station to gradually shape the steel into the desired profile. The automated method ensures tight tolerances, consistent cross-sections, and cost-effective, high-volume production of various steel channel profiles, including C-channels, U-channels, hat channels, and custom designs. After forming, the metal is precisely cut to length, meeting exact project specifications. Roll forming minimizes waste and reduces the need for secondary finishing, making it the preferred method for producing steel channels used in building frameworks, support systems, and racking.

Hot Rolling Process

Hot rolling is a fundamental steel manufacturing technique performed above the metal’s recrystallization temperature. This process makes the steel more malleable, allowing for the shaping of larger, robust structural profiles like I-beams, H-beams, and large steel channels. Hot-rolled steel channels exhibit unique mechanical properties, including directional strength, but may develop residual stresses from uneven cooling. Non-metallic inclusions can sometimes affect microstructure, surface finish, and strength consistency. While hot-rolled steel channels are cost-effective for large-scale structural applications, they may require additional surface finishing to improve corrosion resistance or achieve smoother textures.

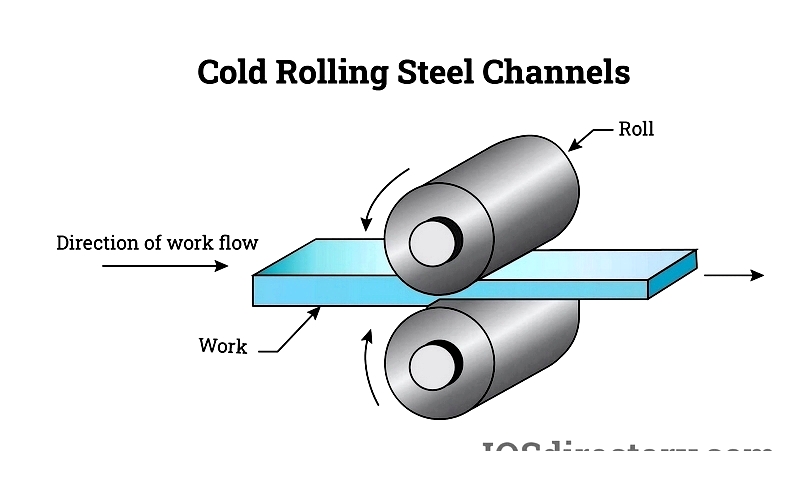

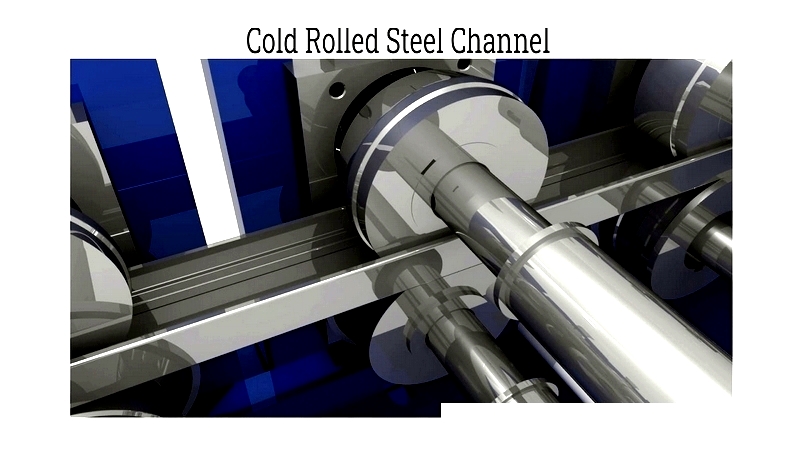

Cold Rolling Process

Cold rolling is an advanced steel forming method conducted at or near room temperature, below the metal’s recrystallization point. This process delivers superior dimensional accuracy, improved surface finish, and increased tensile strength compared to hot-rolled steel. Cold-rolled steel channels are ideal for applications requiring precise tolerances, uniform thickness, and clean surfaces, such as furniture, automotive frames, appliance enclosures, and shelving systems. Cold rolling typically uses four-high or cluster rolling mills to produce slender, strong, and finely detailed metal sections. These products benefit from exacting standards, offering enhanced performance in projects where consistency and aesthetics are critical. Cold-rolled steel also accepts secondary finishes like galvanization and powder coatings with excellent adhesion.

CAD Design & Roll Forming Process

All roll-formed steel products, including custom and standard metal channel profiles, begin with an engineered computer-aided design (CAD) blueprint. This digital specification details the complete geometry, wall thickness, length, and specialized features—such as slots or notches—essential for meeting specific load-bearing, assembly, or installation requirements. Modern CAD software enables quick design iterations, optimizing each component for its intended load capacity, connection method, and environmental exposure. CAD-driven manufacturing allows seamless incorporation of custom punch patterns, mounting holes, or integrated fittings before fabrication begins.

The software provides a step-by-step visualization of how the flat metal will be formed into a channel profile, facilitating tolerance simulation and virtual troubleshooting. CAD-integrated production also automates the conversion of profiles into G codes for robotic CNC roll forming machines, ensuring accuracy from prototype to final production and supporting traceability for certified projects.

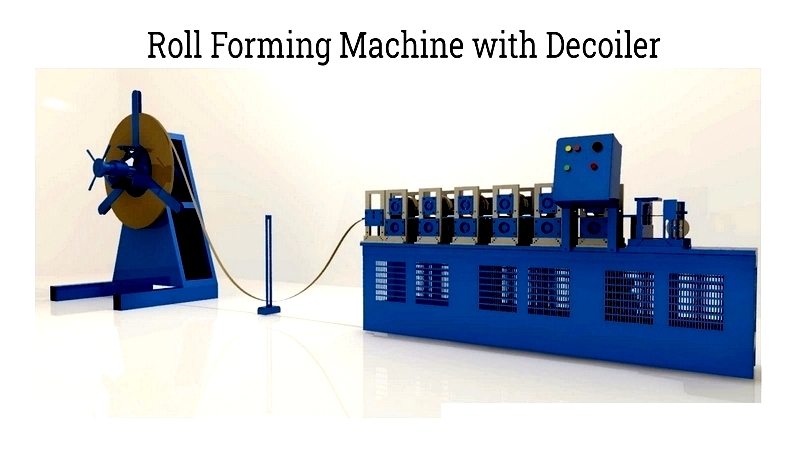

The roll forming sequence begins with feeding a coil of pre-processed metal into an uncoiler or decoiler system, an automated setup critical for high-speed steel channel fabrication. The decoiler unwinds and guides the raw steel into the first forming station, minimizing manual handling and material deformation. Proper uncoiling ensures material flatness, essential for producing straight, dimensionally accurate channel sections for structural and architectural projects.

During inline pre-processing, advanced machinery punches holes, slots, notches, or embossments into the channel, streamlining assembly and enhancing performance. These steps are often automated using programmable press units with tool steel dies, offering flexibility for complex geometries or high-frequency customization, common in industries like HVAC, construction, or automotive manufacturing. Integrated punching ensures accurate placement of features without costly secondary operations.

The roll forming machine is equipped with a series of computer-controlled, precision-crafted dies and rollers—each pass incrementally shapes the channel into its final U, C, or custom configuration. Dies can be tailored for unique structural steel elements, lightweight bracing channels