Introduction

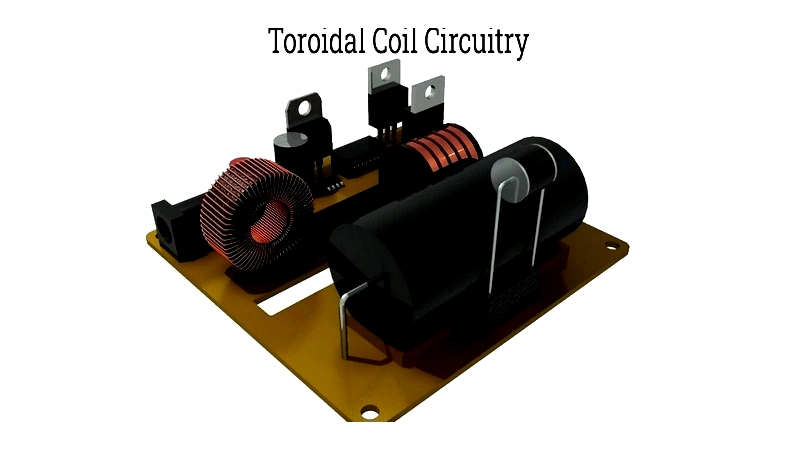

This section covers descriptions, applications, and manufacturers of toroidal inductors and coils, along with their various uses.

You will learn:

- What Toroidal Inductors and Coils Are

- How Toroidal Inductors and Coils Are Made

- Applications of Toroidal Inductors and Coils

- Different Types of Toroidal Inductors and Coils

- And much more...

Chapter 1: Understanding Toroidal Inductors

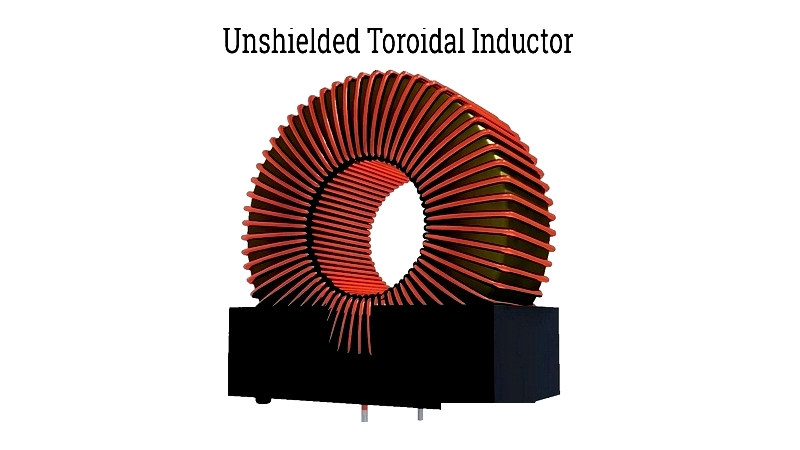

Toroidal inductors and coils are passive electrical components that store energy in magnetic fields while resisting current fluctuations. These components consist of insulated wires wound around donut-shaped cores, which enhance magnetic field strength and inductance. The toroidal shape ensures magnetic field lines form closed loops, confining the field within the core material. This symmetrical design minimizes leakage flux, reducing electromagnetic interference (EMI) compared to other core types.

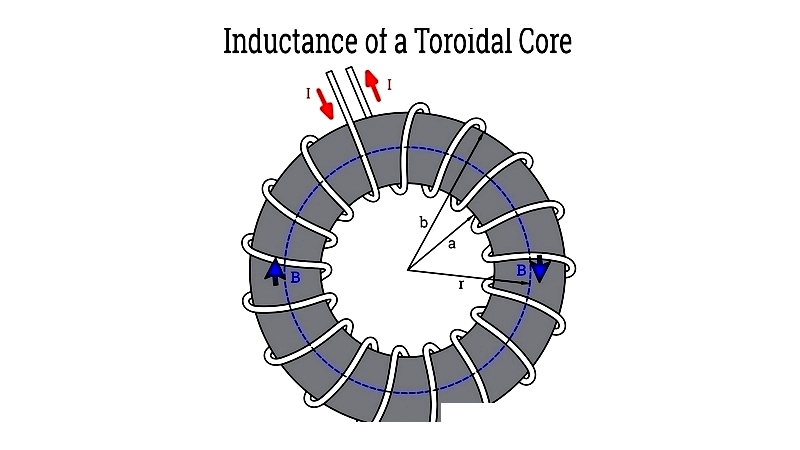

A toroidal inductor or coil derives its name from its toroid shape, resembling a donut or hollow ring. Unlike solenoids, toroids are circular and generate magnetic fields through winding. Their magnetic fields are calculated using Ampere’s circuit law. Typically, toroids are wound with multiple turns of copper wire, forming the basis of toroidal inductors and coils.

The terms "toroidal inductors" and "toroidal coils" are often used interchangeably, as both feature two-terminal components that resist current changes. The wire wrapped around the donut-shaped core creates a magnetic field, which stores energy when electricity flows through the inductor.

Toroidal inductors and coils function through inductance, filtering ripple currents at the output. Higher inductance values reduce ripple currents, improving circuit efficiency and lowering EMI. Inductance resists changes in current rather than opposing it directly. When paired with capacitors, toroidal inductors and coils form tuned LC circuits, crucial for transmitting and receiving radio and microwave signals.

Ampere’s circuit law is used to calculate the magnetic field in a toroid. André-Marie Ampère, who studied forces on current-carrying wires, established this principle. His work laid the foundation for electromagnetism, coinciding with Michael Faraday’s development of Faraday’s law.

Ampere’s law states that magnetic fields are linked to the electric currents producing them, maintaining this relationship as long as the electric field remains constant. Conductors carry currents, generating magnetic fields around the wires. The circular design of toroidal inductors and coils effectively contains electromagnetic fields, preventing their escape.

Chapter 2: How a Toroidal Inductor Works

Square cores have long been used as inductors but suffer from inefficiency due to high leakage flux. Toroidal cores, with their symmetrical shape, provide superior magnetic confinement, reducing leakage flux and EMI. This makes them ideal for high-efficiency electronic circuits. Common applications include power supplies, audio amplifiers, inverters, and switching power supplies. Their ability to handle large inductance requirements while minimizing EMI and RFI has increased demand across the electronics industry, leading to specialized designs for compactness, high power, or high-temperature tolerance.

Toroidal or Doughnut Shaped Circular Core

Toroidal inductor cores are made from magnetic materials with varying resistivity, hysteresis, and permeability. Common materials include ferrite, powdered iron, nanocrystalline alloys, and amorphous metals, chosen based on impedance, frequency response, and efficiency. Higher resistivity reduces eddy current losses, critical for high-frequency designs. These cores resist alternating current while smoothing voltage or current fluctuations, performing functions like filtering, energy storage, and voltage regulation.

Hysteresis, the lag between magnetic flux density and field strength, is crucial in power electronics and SMPS, as it affects system efficiency. Understanding hysteresis loops helps engineers select cores with optimal retentivity and coercivity, balancing performance with energy loss in chokes and transformers.

Magnetic permeability determines how easily a material enhances a magnetic field, influencing core loss and energy handling. High permeability allows toroidal inductors to achieve high inductance with fewer windings and low core loss, suitable for DC-DC converters and EMI filters. Permeability ranges from 750 µ to over 15,000 µ, accommodating both low and high-frequency circuits.

Toroidal inductors excel in low-frequency applications, maintaining large inductances and signal integrity. Their closed-ring design minimizes stray magnetic fields compared to solenoids. Advances in toroidal technology continue to meet diverse needs in power management, signal filtering, and noise suppression across industries.

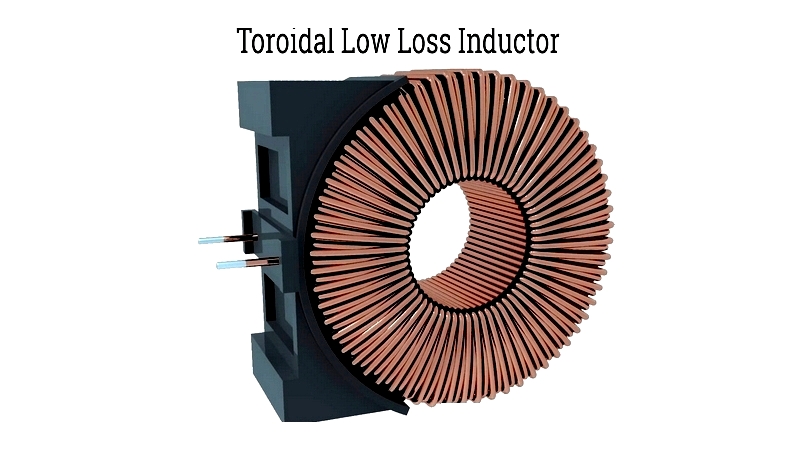

Low Loss Toroidal Inductor

Low loss toroidal inductors are designed for high efficiency and current management in power electronics. Often vertically mounted, they optimize PCB space while maintaining thermal and electrical performance. Advanced core materials and air gaps minimize losses, making them ideal for switching power supplies, DC-DC converters, and RF filters. Shielding ensures EMI/RFI protection, complying with EMC standards. Low magnetostriction materials reduce acoustic noise, benefiting telecom, medical, and industrial electronics. Their efficient flux paths and thermal stability ensure reliable performance.

High Temperature Toroidal Inductors

High temperature toroidal inductors withstand up to 200°C (392°F), making them suitable for automotive powertrains, EV charging stations, solar inverters, and industrial automation. Without high-temperature materials, standard inductors risk degradation or saturation under thermal stress. The Curie temperature defines when a core loses magnetism, critical for reliability. These inductors ensure stable inductance and minimal loss in extreme environments.

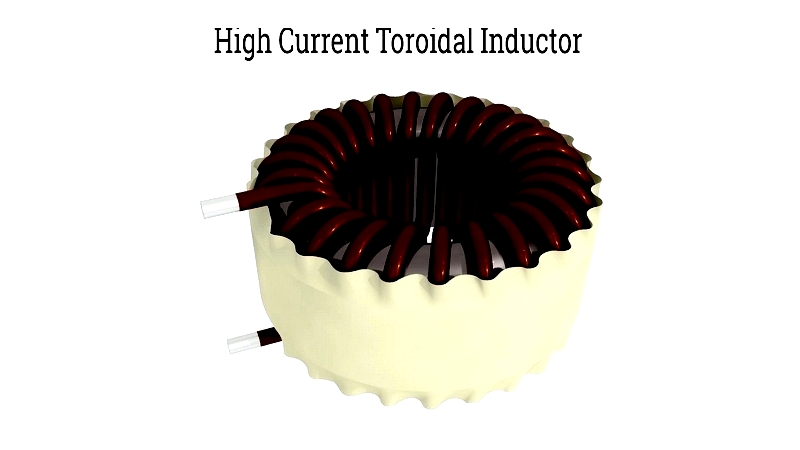

High Current Toroidal Inductors (HCTI)

HCTIs feature high-frequency characteristics, broad inductance, and high current capacity, ranging from 10 µH to 1000 µH and 2.4 A to 20 A. They minimize stray EMI and dissipate heat efficiently, ideal for power supplies, battery systems, and energy storage. Configurable for vertical or horizontal mounting, they suit compact designs while handling high ripple currents in industrial and automotive applications.

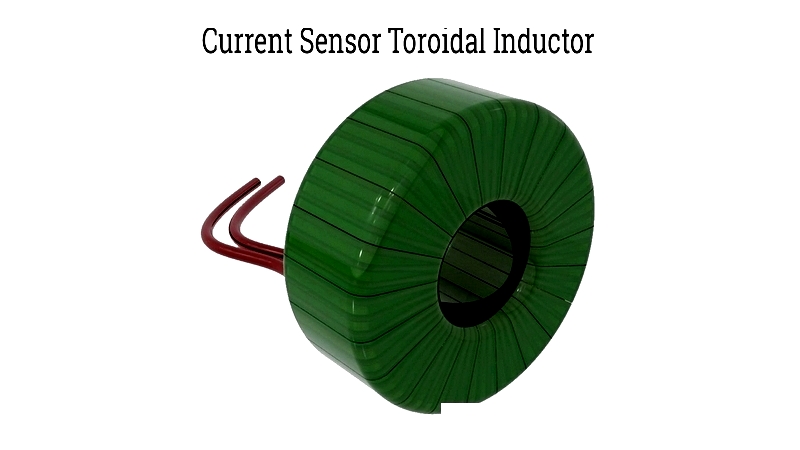

Current Sensing Toroidal Inductor

These inductors use permeable cores and precise windings to measure AC current accurately. They step down currents for monitoring with ammeters or transducers, excelling in power generation, smart metering, and protective relays. Their closed magnetic circuit ensures stability and low noise in grid inverters and process control.

Fluxgate current transducers in toroidal inductors modulate core flux using drive and sense windings, producing low-distortion AC signals proportional to primary current. Their design supports closed-loop operation in current transformers, offering superior isolation and bandwidth.

Current sensing toroidal inductors are vital for smart grids, renewable energy, and motor drives, enabling precise power management and control.

Direct Current (DC) Resistance (DCR) Inductors

Toroidal inductors block high-frequency AC while allowing DC, useful in noise filters and DC chokes. DCR represents resistance at 0 Hz, affecting efficiency and heat dissipation. Low DCR is crucial for power supplies, VRMs, and audio crossovers to minimize loss and thermal load.

DCR ranges from <1 Ω to ~4 Ω, depending on wire gauge and core design. Excessive DCR causes voltage drop and