Introduction

This article provides comprehensive information about hydraulic presses.

You'll explore various topics including:

- What a hydraulic press is

- How hydraulic presses operate

- Different types of hydraulic presses

- Applications of hydraulic presses

- And more...

Chapter One: What is a Hydraulic Press?

A hydraulic press is a mechanical device that utilizes liquid static pressure based on Pascal's principle. It's used to form, reshape, and modify materials like metals, plastics, rubber, and wood. The key components include the mainframe, power system, and control mechanisms.

Pascal's principle states that pressure applied to a confined fluid transmits equally throughout the liquid. In hydraulic presses, this pressure originates from a piston that functions like a pump to generate mechanical force.

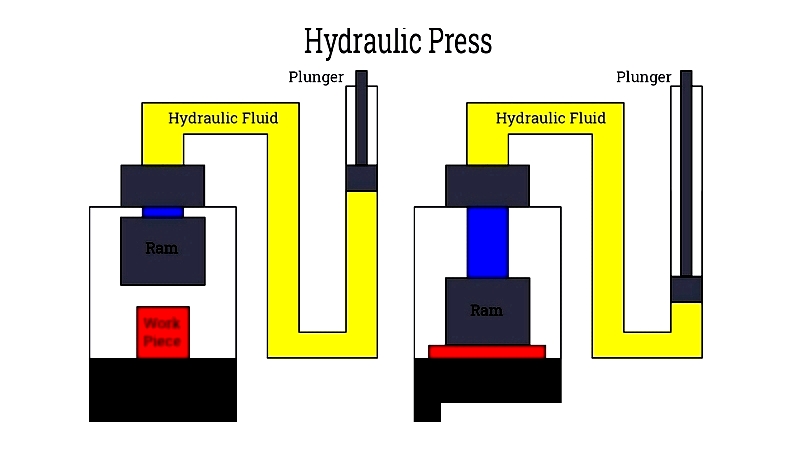

Chapter Two: How a Hydraulic Press Works

Hydraulic presses are powerful machines extensively used in industrial applications for metal forming, assembly, molding, and material compaction. They operate by directing hydraulic fluid into a double-acting piston, utilizing Pascal's Law to amplify force for heavy-duty operations. The compressive force from the smaller cylinder pushes hydraulic oil into a larger cylinder, creating greater force and pressure. As the larger piston moves, it returns fluid to the smaller cylinder, maintaining consistent system pressure.

This fluid exchange between pistons builds mechanical pressure, generating the substantial force required to drive the press anvil downward onto workpieces for shaping, compacting, or cutting. After completing the forming process, pressure releases safely, allowing the anvil and die to reset. Hydraulic presses are prized for their precision, repeatability, and versatility in material processing, making them essential in manufacturing, automotive, aerospace, and fabrication industries.

Hydraulic Press Components

A standard hydraulic press contains two cylinders, two pipes, and two pistons. One cylinder serves as the ram, the other as the plunger, connected by a high-strength chamber filled with specialized hydraulic oil. This configuration enables the powerful compression capabilities hydraulic presses are known for.

- Main Cylinder (Ram): Applies force to workpieces

- Plunger: Initiates pressure transfer by pushing hydraulic fluid

- Pipes and Hoses: Ensure secure fluid transfer between components

- Hydraulic Fluid Reservoir: Stores and supplies fluid for continuous operation

- Control Valves: Manage fluid flow and pressure for precise operations

Ram

Advanced systems use multiple rams based on workload requirements. Multiple smaller rams provide better control over thrust force, crucial for precision metal forming. Hydraulic pumps and accumulators route fluid to these rams, moderating pressure for high-tonnage applications like deep drawing or blanking.

Accumulator

This vital component stores pressurized hydraulic fluid, releasing it as needed to maintain system efficiency. Typically featuring a durable cylinder with a spring-loaded or pneumatic piston, accumulators act as energy storage devices. They enable quick response to demands without continuous pump operation, ensuring consistent performance in heavy manufacturing while improving energy efficiency and reducing wear.

Pump

Hydraulic presses primarily use three pump types: vane, gear, and piston, with piston pumps dominating high-performance equipment. Positive displacement pumps deliver precise oil volumes per cycle, maintaining forces needed for automotive and metal applications. Available as fixed or variable models, piston pumps (axial, bent axis, or radial) excel in high-pressure environments, offering superior efficiency and minimal leakage.

Cylinders

Cylinder quantity and size depend on press design and tonnage requirements. In typical two-cylinder configurations, the larger ram cylinder generates maximum force while the smaller plunger cylinder initiates fluid movement. Constructed from pressure-rated steel, these cylinders feature ports for controlled fluid circulation during heavy pressing operations.

Interconnected via hydraulic pipes, these cylinders transfer force when the plunger applies pressure to hydraulic oil. This linear actuator-driven force enables consistent motion for metalforming, compression molding, and precision stamping applications.

Hydraulic Press Operation

The hydraulic press process underpins modern metal forming and fabrication. System pressure drives the main ram downward, precisely compressing workpieces in die cavities. This creates repeatable results for automotive, aerospace, and electronics components. With adjustable force, stroke length, and speed, hydraulic presses suit diverse processes including forging, deep drawing, and powder metallurgy.

Selecting the Right Hydraulic Press requires evaluating tonnage needs, workspace dimensions, safety features, energy efficiency, and cycle speeds. Leading manufacturers offer customized solutions for metal stamping, plastic injection, and other applications. When comparing models, consider component quality, technical support, and maintenance requirements to ensure long-term reliability and ROI.