Introduction

This article provides detailed information about steel forging.

You will learn about:

- What is Steel Forging?

- The Steel Forging Process

- Equipment Used for Steel Forging

- Types of Steel and Alloys Used in Forging

- How to Select a Steel Forging Alloy

- And much more...

Chapter One: Understanding Steel Forging

Steel forging is a manufacturing process that shapes steel using compressive forces like hammering, pressing, and rolling. This technique produces high-quality steel components with precise tolerances. Forging steel involves combining iron and carbon under controlled conditions to achieve optimal ductility, fatigue resistance, tensile strength, and grain structure.

Steel forging processes are categorized into three main types: cold, hot, and hardened forging, each defined by specific temperature and pressure conditions. This shaping method gives forged steel unique characteristics that distinguish it from cast steel, including improved density, anisotropy, and uniformity.

The forging process enhances metal strength, making it ideal for mechanical and industrial applications. Forged components are highly reliable due to their consistent composition and structure, capable of withstanding significant loads and stress. They are also free from voids and imperfections that could cause failure.

Chapter Two: The Steel Forging Process

Understanding the steel forging process is essential when evaluating industrial metalworking methods or sourcing high-performance components. Does every forging process apply force to heated or room-temperature steel billets? How do hot, cold, and warm forging techniques differ? How does temperature affect the choice of forging dies, hydraulic presses, mechanical hammers, and other equipment? While compressive force and billet ductility are key factors, do alloy composition and forging environment also impact final product properties?

Design and Engineering Planning

Successful steel forging begins with robust design and careful engineering. For closed die forging, engineers create dies shaped to the final product, considering metal flow and tolerances. Open die forging and other methods also rely on detailed drawings and simulations to determine force application. CAD models and forging simulation software help predict deformation, reduce waste, and optimize component properties. This foundation ensures steel products meet performance standards for strength, fatigue resistance, and durability.

Billet Cutting and Selection

Billets, produced through hot rolling or continuous casting, serve as raw material for forging. These steel billets, typically square or rectangular, are cut to specified lengths for consistency. Selecting the right steel grade is critical, considering alloy content, carbon percentage, and grain structure. The choice depends on end-use requirements like corrosion resistance, weldability, and mechanical strength. Precise billet cutting minimizes waste and optimizes forming.

Temperature Control: Hot, Warm, and Cold Forging

Temperature determines the forging method. Hot forging heats billets above recrystallization temperature (900°C to 1250°C) for maximum ductility, enabling complex shapes. Cold forging works at ambient temperatures, requiring greater force but offering superior accuracy and strength. Warm forging provides a balance between formability and strength. The optimal temperature depends on material grade, part complexity, and performance needs.

The Comprehensive Steel Forging Process

Various forging methods meet diverse product demands:

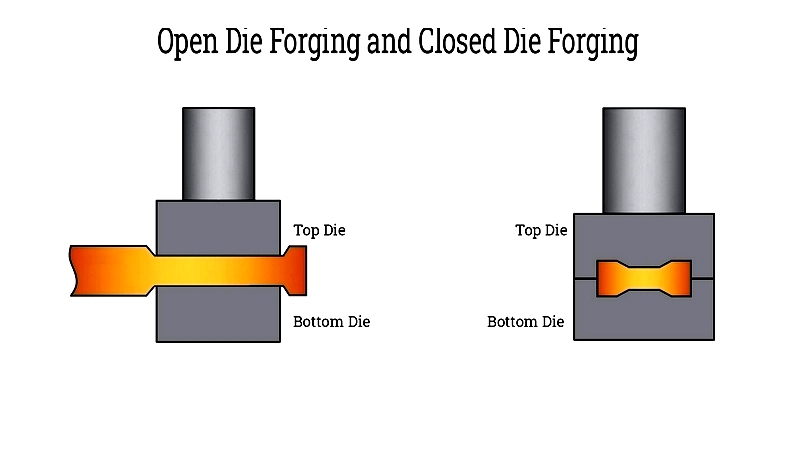

- Open Die Forging: Uses flat dies for large custom components like shafts and rings, common in heavy industry.

- Closed Die Forging: Shapes metal in precise cavities for repeatable production of complex parts.

- Roll Forging: Uses cylindrical rollers to contour billets for products like axles.

- Cold Forging: Forms steel without heating, ideal for high-volume production of fasteners.

- Extrusion and Upset Forging: Creates long lengths with uniform cross-sections, typical for railings.

These processes differ in pressure application, die configuration, and part complexity. Forged steel is used in aircraft landing gear, turbine blades, gears, and tools where strength and integrity are vital.

Finishing and Precision Machining

Finishing ensures forged parts meet surface and dimensional specifications. Processes like grinding, polishing, and CNC machining remove defects and achieve final dimensions. Secondary machining is often applied to critical tolerances for optimal performance.

Shot Blasting for Superior Surface Quality

Shot blasting bombards parts with abrasives to remove scale and impurities. This enhances surface finish and improves paint adhesion, crucial for corrosion protection in automotive and structural components.

Heat Treatment Processes

Heat treatment optimizes mechanical properties like strength and toughness. Processes include:

- Annealing: Heats steel to sub-critical temperatures to reduce stress and improve machinability.

- Normalizing: Restores ductility and grain uniformity for load-bearing applications.

- Quenching: Rapid cooling increases hardness for wear-resistant parts.

- Tempering: Adjusts hardness and toughness balance to reduce brittleness.

- Spheroidizing: Enhances ductility and machinability in high-carbon steels.

Surface Treatment and Corrosion Protection

Final treatments include basic cleaning or advanced methods like galvanizing and powder coating. These enhance corrosion resistance and meet industry standards for durability.

Chapter Three: Alloying Steel for Forging

Selecting the right alloyed steel is crucial for forging, as alloying elements enhance properties like hardness, strength, and corrosion resistance. Common elements include chromium, molybdenum, nickel, and vanadium. Steels are classified by alloy content: high alloy (over 8%) and low alloy. Understanding these distinctions ensures optimal material selection for aerospace, automotive, and industrial applications.

Carbon Steel

Carbon content defines steel performance. Increasing carbon enhances hardness and strength but reduces ductility. Carbon steels are categorized as plain, low, or high carbon. Stainless steels, with at least 12% chromium, offer excellent corrosion resistance.

SAE Steel Designations

The SAE system uses four-digit codes to identify steel types. The first digit indicates the category (e.g., 1 for carbon steels), while subsequent digits specify alloy content and carbon percentage. Additional letters denote special properties.

Steel Alloys Used for Forging

Alloy steels are versatile for forging, offering customizable properties. Key alloys include:

- Manganese: Improves toughness and abrasion resistance.

- Molybdenum: Enhances creep strength and hardenability.

- Nickel: Boosts toughness and corrosion resistance.

- Vanadium: Increases strength and impact resistance.

Choosing a Steel Alloy for Forging

Selecting the right alloy involves balancing performance, process requirements, and cost. Consider mechanical properties, forgeability, and heat treatment response. Partnering with material suppliers ensures optimal selection for specific applications.

Chapter Four: Selecting a Steel Supplier

Choosing a steel