Introduction

This article provides an in-depth exploration of trash compactors and their applications.

You will learn about various topics, including:

- What is a Compactor?

- Types of Compactors

- How Compactors are Used

- How a Compactor Works

- Benefits of Compactors

Chapter One – What is a Trash Compactor?

When a compactor reaches a predetermined threshold, it compresses materials into a denser state by removing air, liquids, and moisture. The primary purpose of a compactor is to reduce waste volume within a container, allowing for more efficient storage and transportation.

The compacting process involves the following steps:

- Collecting materials through mechanical or manual methods.

- Activating the compactor once the specified load capacity is reached.

- Emptying the compactor by loading and transporting the compacted waste.

Compacting effectively minimizes waste bulk and footprint, making management easier and more cost-effective. Trash compactors offer a sustainable waste solution, ensuring clean and safe waste removal. By reducing waste volume and mass, compactors help conserve landfill space.

Chapter Two – What are the types of trash compactors?

In modern industrial settings, choosing the right trash compactor is essential for efficient waste management, regulatory compliance, and workflow optimization. Industrial compactors play a key role in reducing waste volume, streamlining recycling, controlling costs, and meeting environmental regulations. As waste streams diversify across industries, selecting the appropriate compactor system becomes a critical part of waste handling strategies.

Different industries generate various waste types, each requiring specialized compaction equipment for maximum efficiency and safety. Waste composition and volume determine whether a facility needs a self-contained, stationary, or other specialized compactor. Common commercial and municipal waste streams include:

Waste Categories:

- Wet Waste – Organic waste, food scraps, hygiene products, soiled packaging, used tissues, and paper towels. Specialized liquid-tight compactors are necessary to manage odors and prevent leaks.

- Dry Waste – Recyclables like mixed paper, cardboard, plastics (PET, HDPE, LDPE), aluminum cans, textiles, and rubber. Dry waste compactors reduce haul frequency and improve recycling rates.

- Bulky Waste – Large items such as pallets, industrial drums, appliances, scrap metal, and furniture. Reducing bulky waste optimizes landfill space and lowers hauling costs.

Common compactor types include:

- Self-Contained Compactors – Ideal for wet waste or liquids, preventing spills during compaction and transport.

- Stationary Compactors – Designed for dry waste, including cardboard and general trash. Variants include transfer station and loading dock compactors, tailored for specific waste volumes.

- Auger Compactors – Use a rotating auger to crush and compact bulky waste, suitable for commercial and industrial streams.

- Bag Compactors – Compress lightweight plastic or paper bags, controlling dust and simplifying recycling.

- Chute-Fed Compactors – Integrated with buildings to streamline waste collection from multiple floors.

- Portable Trash Compactors – Mobile units for temporary sites or locations with space constraints.

- Pre-Crusher Compactors – Reduce large or dense waste volume before final compaction, maximizing bin efficiency.

- Vertical Compactors – Space-saving units that compress waste vertically, ideal for tight spaces.

Auger Compactor

An auger compactor features a rotating screw mechanism that crushes and propels waste into a storage container. It efficiently processes bulky items like wood crates, plastic drums, and packaging materials, making it popular in recycling and manufacturing facilities. Auger compactors minimize manual handling, improve safety, and reduce landfill trips. However, they are unsuitable for liquid waste.

Bag Compactor

Bag compactors are designed to compress lightweight waste bags, such as those used in retail or commercial kitchens. They feature dust collection systems for a cleaner work environment. Operators load bags into the compactor, which compresses them into removable bins for easy transport. Sizes range from 50 to 150 gallons.

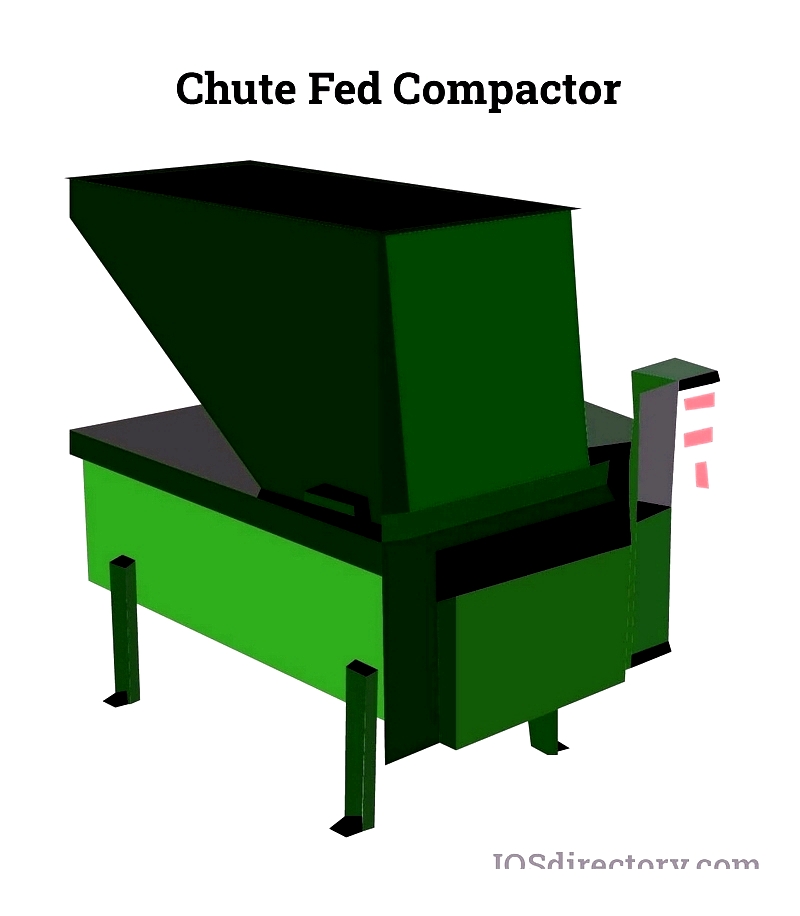

Chute Fed Compactors

Chute-fed compactors are ideal for multi-story buildings like hospitals and hotels. Waste enters through a chute, eliminating manual collection between floors. Automated sensors trigger compaction when needed, and full-bin indicators alert operators for service. These compactors handle both wet and dry waste.

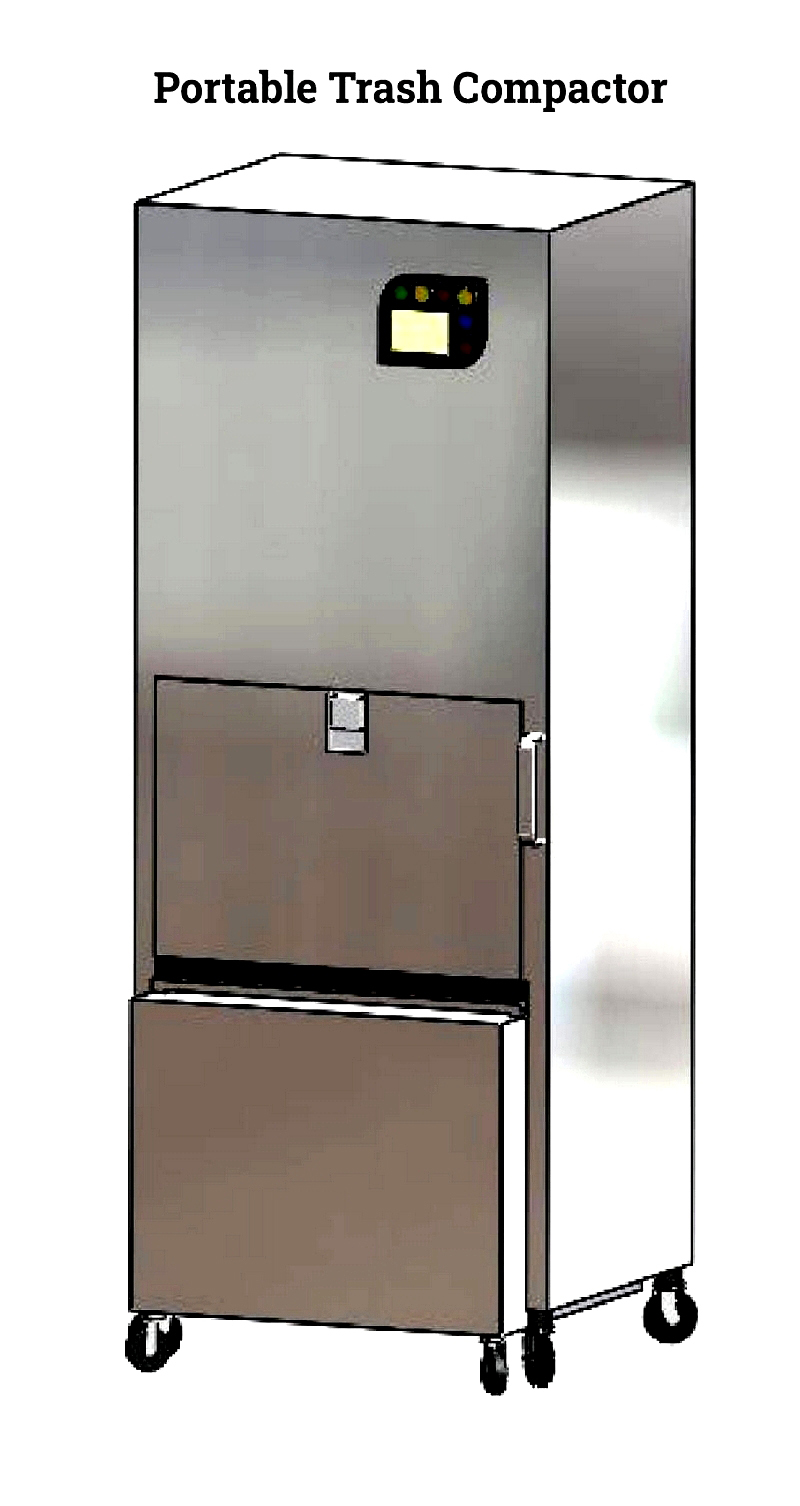

Portable Trash Compactor

Portable compactors offer mobility for facilities with changing needs or limited space. Suitable for retail, restaurants, and schools, they reduce waste volume and labor costs. Features include safety locks, odor control, and easy front-loading doors.

Pre-Crusher Compactor

Pre-crusher compactors break down oversized waste before final compaction. They handle furniture, pallets, and industrial materials, reducing bulk volume and transportation costs. These compactors also serve as product destruction equipment.

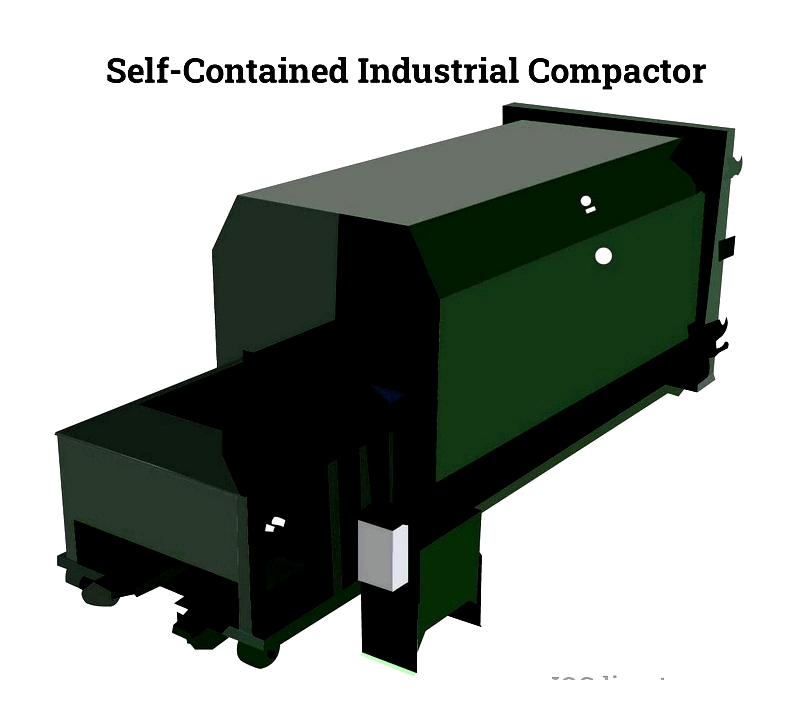

Self-Contained Compactors

Self-contained compactors manage wet waste and liquids, preventing leaks and odors. Common in supermarkets and hospitals, they combine the compaction chamber and container for easy transport. Separate power packs enhance serviceability.

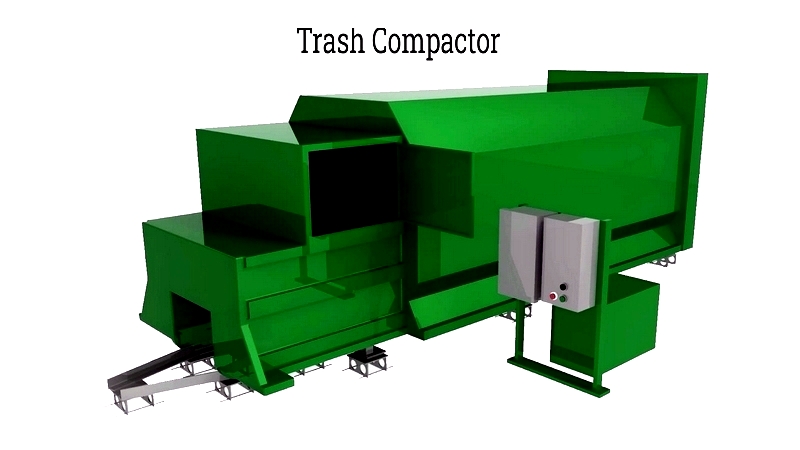

Stationary Compactors

Stationary compactors are permanent installations for dry waste like cardboard and plastics. They optimize recycling and reduce haul frequency. Waste can be deposited manually or via conveyors, with roll-off containers swapped as needed.

Vertical Compactors

Vertical compactors save space by compressing waste vertically. Ideal for restaurants and schools, they handle both wet and dry waste. Capacity indicators ensure timely emptying, and multiple containers simplify recycling.