Introduction

This article provides an overview of gasket categories, properties, and applications. Continue reading to explore:

- Gasket Definition

- Gasket Manufacturing Process

- Gasket Varieties

- Gasket Selection Criteria

- Common Causes of Gasket Failure

- Additional Relevant Information

Chapter 1: Understanding Gaskets

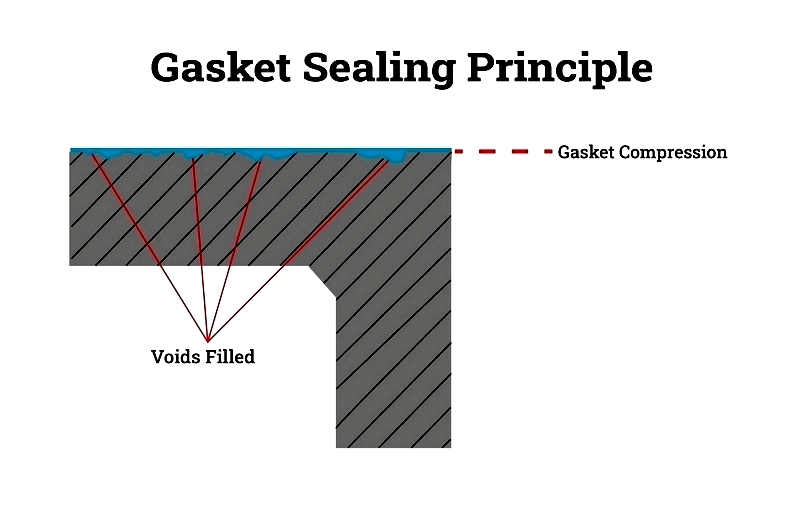

Gaskets serve as mechanical seals designed to prevent leaks by filling gaps between stationary mating surfaces. Even polished metal surfaces contain microscopic imperfections that can create leakage paths. When compressed, gaskets conform to surface contours, effectively sealing these imperfections by matching surface irregularities.

Industries widely use gaskets in both pressurized and non-pressurized fluid and gas systems. They're essential components in fluid-containing equipment like piping systems, storage tanks, heat exchangers, and internal combustion engines. Available in multiple configurations, gaskets are engineered to meet specific application requirements.

Gaskets vs. O-Rings: Key Differences

While both gaskets and O-rings prevent fluid or gas leakage in mechanical systems, they differ in design, configuration, and application. The main distinctions include:

Shape and Design

- Gaskets: Typically flat or custom-shaped, made from materials like rubber, metal, or composites, tailored to specific sealing requirements.

- O-rings: Feature a uniform toroidal shape with circular cross-section, primarily made from elastomers like rubber or silicone.

Cross-Section

- Gaskets: May have various cross-sectional profiles (flat, oval, etc.) designed for specific sealing surfaces.

- O-rings: Maintain consistent circular cross-sections for uniform sealing in grooves.

Application

- Gaskets: Primarily used in static sealing applications like flanges and pipe connections.

- O-rings: Ideal for dynamic sealing in hydraulic systems and rotating components.

Sealing Mechanism

- Gaskets: Create seals by compressing material between surfaces to fill imperfections.

- O-rings: Form seals through radial compression in grooves.

Materials

- Gaskets: Utilize diverse materials including metals and composites.

- O-rings: Typically made from specialized elastomers.

Installation

- Gaskets: Installed between surfaces with fasteners requiring proper torque.

- O-rings: Press-fit into grooves during assembly.

Versatility

- Gaskets: Adaptable to various sealing challenges.

- O-rings: Specialized for dynamic applications.

Gaskets and Seals: Distinct Components

While both prevent leaks, gaskets and seals serve different purposes. Gaskets specifically fill gaps between stationary surfaces, while seals encompass broader sealing solutions including dynamic applications.

Relationship Between Gaskets, O-Rings, and Seals

These components share sealing functions but differ in design and application:

Common Features

- All prevent fluid/gas leakage

- Available in various materials

- Rely on compression for sealing

Key Differences

- Seals: Broad category including various designs

- O-rings: Specialized for dynamic applications

- Gaskets: Designed for static sealing

Chapter 2: Gasket Manufacturing Processes

Gasket production requires precision and material expertise for industries like automotive and aerospace. Manufacturing methods vary based on material (rubber, metal, etc.) and application requirements (pressure, temperature, etc.). Proper material selection directly affects performance and durability.

Rotary Die Cutting

This high-speed method uses cylindrical dies to cut non-metallic materials, ideal for mass production of uniform gaskets.

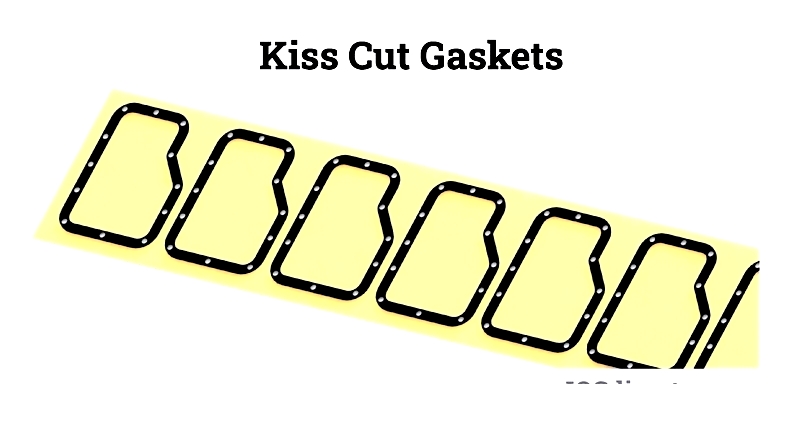

Kiss Cutting

Partial-depth cutting that leaves gaskets attached to backing material, convenient for adhesive applications.

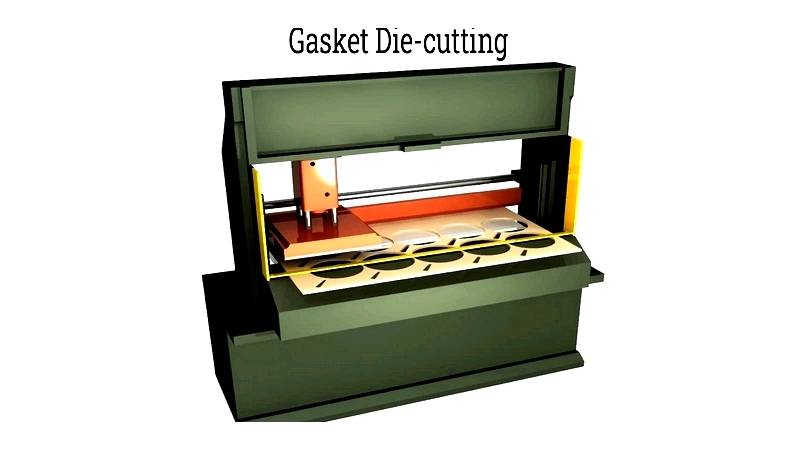

Press Die Cutting

Traditional stamping method suitable for metal and rigid gaskets, using hydraulic or mechanical presses.

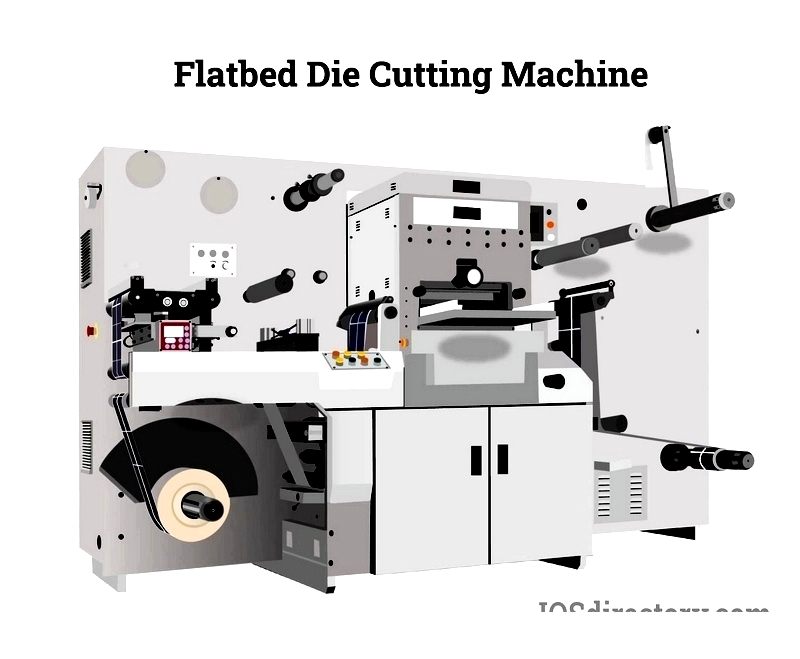

Flatbed Die Cutting

Cost-effective solution for prototypes and small batches, using stationary dies.

Knifeless Die Cutting

CNC-controlled process eliminating physical dies, offering design flexibility for prototypes.

Waterjet Cutting

Cold-cutting process using high-pressure water, suitable for sensitive materials.

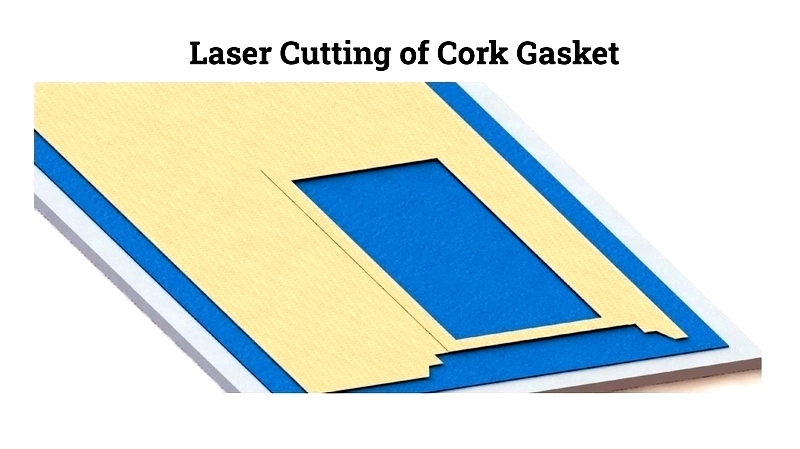

Laser Cutting

High-precision method capable of intricate designs with tight tolerances.

Compression Molding

Heat and pressure form rubber compounds into finished gaskets, ideal for elastomeric products.

Rubber to metal Bonding

Specialized process creating durable composite gaskets through chemical bonding.

Selecting the appropriate manufacturing method depends on material properties, production volume, tolerance requirements, and cost considerations. Consulting with experienced manufacturers ensures optimal gasket solutions for specific applications.