Introduction

This article provides comprehensive information about laser cutting and drilling. Continue reading to learn about:

- What are Laser Cutting and Laser Drilling?

- Theory and Working Principles

- Cutting Methods

- Laser Drilling Techniques

- And more...

Chapter 1: Understanding Laser Cutting

Laser cutting is an advanced material processing technique that uses a highly concentrated, coherent light beam. This method effectively cuts through metals, paper, wood, and acrylics. As a subtractive manufacturing process, it removes material through vaporization, melting, chemical ablation, or controlled crack propagation. Using CNC-powered laser optics, it can create holes as small as 5 microns (µ). A key advantage is minimal residual stress on workpieces, making it suitable for delicate and brittle materials.

Laser drilling employs various techniques including single-shot, percussion, trepanning, and helical methods. While single-shot and percussion drilling offer rapid hole production, trepanning and helical methods provide superior precision and hole quality.

As a non-contact process, laser cutting slices materials without physical interaction. This makes it ideal for high-strength or brittle items like diamond tools and refractory ceramics. First introduced in 1965 for drilling diamond dies, laser cutting expanded to robust alloys and metals like titanium in aerospace. Today, it's widely used for diverse materials including polymers, semiconductors, gems, and metallic alloys.

Chapter 2: The Theory and Working Principle of Laser Cutting

Laser stands for "light amplification by stimulated emission of radiation." In modern manufacturing, laser technology is crucial for precision cutting, metal fabrication, and rapid prototyping. Beyond metal cutting, lasers are used for joining, heat treating, quality inspection, engraving, and freeform manufacturing. Unlike other laser processes, laser cutting requires higher power densities but shorter interaction times, producing clean cuts in materials like stainless steel, aluminum, plastics, and composites.

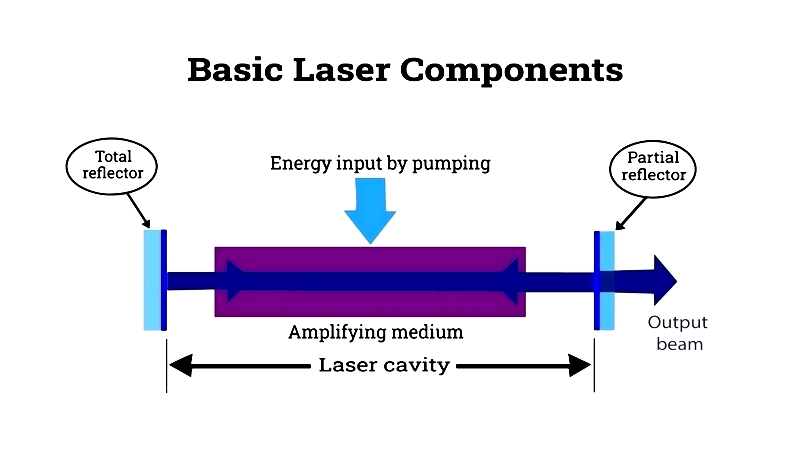

Lasers are generated by a high-intensity light source in a reflective cavity containing a laser rod. The light source stimulates atoms in the rod to absorb specific light wavelengths. Photons energize these atoms, which then emit two additional photons matching the original's wavelength, direction, and phase through stimulated emission. This creates a photon cascade, producing a concentrated, coherent light source ideal for precision cutting.

The photons travel between parallel mirrors at the laser rod's ends. One partially transmissive mirror allows some light to escape as the laser beam. Additional mirrors or fiber optics direct this light to a focusing lens, narrowing it to a fine point for high-precision processing. This focused energy enables clean cuts, micro-machining, and high-speed manufacturing.

The three main industrial laser types are CO₂ lasers, Nd-YAG lasers, and fiber-optic lasers, each with unique lasing media and operational principles for different materials and thicknesses.

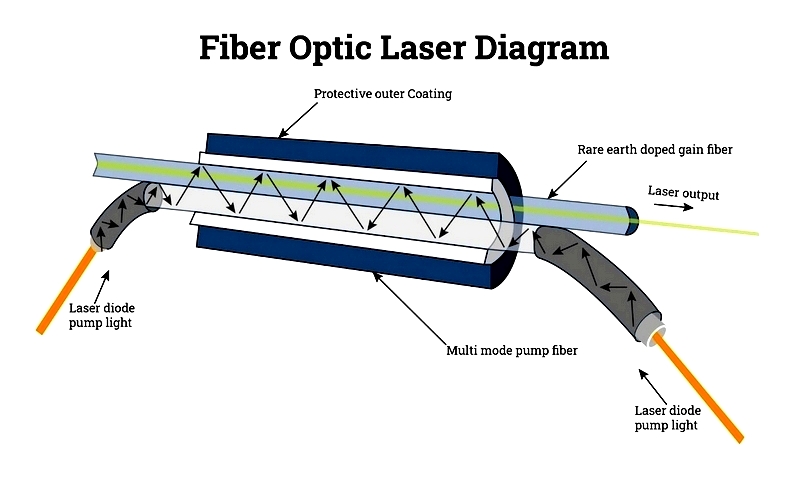

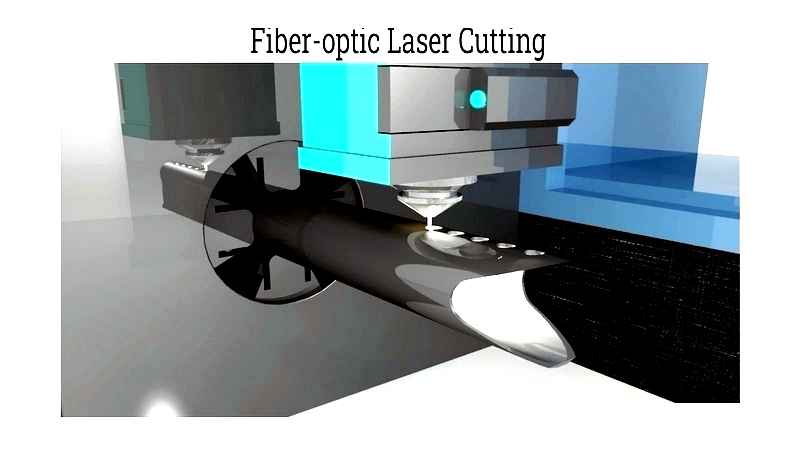

Fiber-optic Laser

Fiber-optic lasers are the newest and most versatile, generating multiple wavelengths for enhanced precision. These fiber lasers use silica glass fiber doped with rare earth elements to guide and amplify light. The resulting beam is straighter and narrower, offering exceptional accuracy for metal cutting, etching, and automated manufacturing.

Fiber lasers vary by doping elements (ytterbium, thulium, erbium), each producing specific wavelengths for different materials. For example, erbium generates 1528-1620 nm light for telecommunications, while ytterbium produces 1030-1080 nm light for industrial applications.

Available in single-mode (8-9 µm core) for micro-machining and multi-mode (50-100 µm core) for thicker cuts, single-mode lasers offer superior beam quality for intricate designs. As solid-state lasers, they differ from gas lasers like CO₂, delivering 780-2200 nm wavelengths for thin sheets, engraving, and marking. CO₂ lasers (9600-10600 nm) better suit organic materials like wood and acrylic.

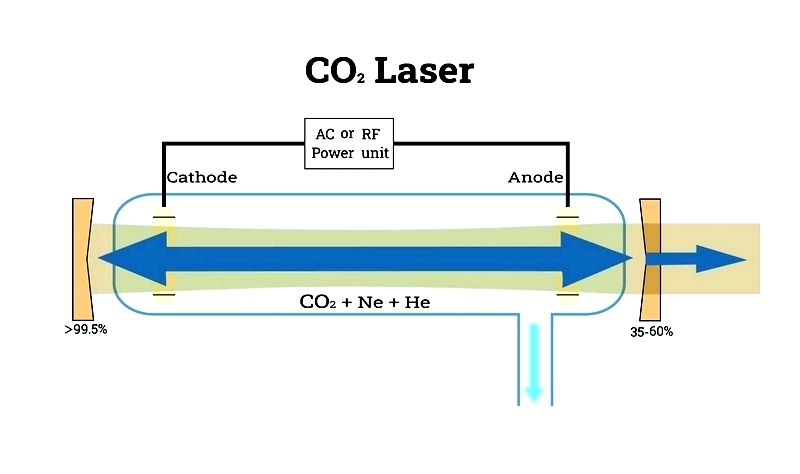

CO₂ Lasers

CO₂ lasers remain fundamental in laser cutting, using a gas mixture of 10-20% CO₂, 10-20% nitrogen, and trace gases. Electrical discharge excites nitrogen molecules, which transfer energy to CO₂ molecules, emitting powerful 10.6 µm or 9.6 µm infrared light. With 30% efficiency, they're ideal for organic materials and thick non-metals.

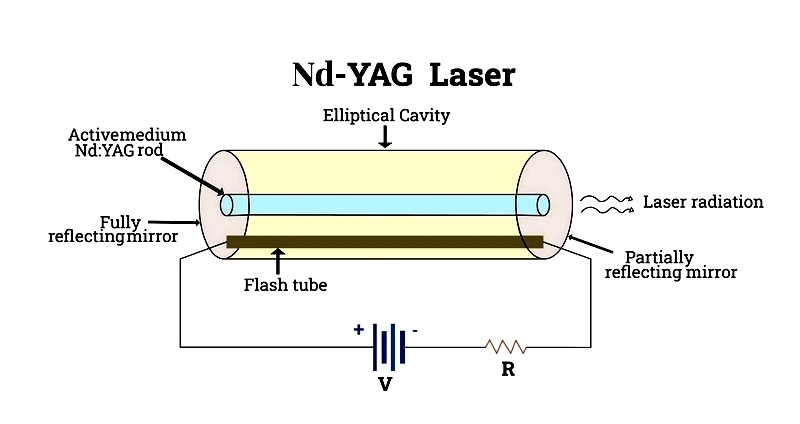

Crystal (Ruby, Nd, and Nd-YAG) Lasers

Crystal lasers like Nd-YAG lasers offer precision cutting and micro-fabrication capabilities. Using a YAG crystal doped with neodymium ions, they produce 1064 nm infrared light, suitable for welding, drilling, and medical applications. Excited by flashlamps or diodes, these solid-state lasers are valuable for detailed machining and micro-welding.

Fiber-optic Laser

Fiber-optic lasers maintain consistent power delivery with minimal energy loss, enhancing cutting stability. Requiring less maintenance than CO₂ or crystal lasers, they're ideal for automated manufacturing. Their efficiency makes them preferred for precision work with reflective or sensitive materials.

Assist Gases

Laser cutting uses assist gases like nitrogen, oxygen, or argon to improve the process. Oxygen accelerates steel cutting through exothermic reactions, while nitrogen produces clean edges on stainless steel and aluminum. Proper gas selection affects cut speed, kerf width, and surface finish for aerospace and automotive applications.

With optimized parameters, laser cutting delivers high precision, fast turnaround, and excellent edge quality, making it ideal for advanced manufacturing and prototyping.