Introduction

This article provides comprehensive details about cylinder brushes, covering:

- What Cylinder Brushes Are

- Fill Materials Used in Cylinder Brushes

- Different Types of Cylinder Brushes

- Cylinder Brush Patterns

- Mounting Options for Cylinder Brushes

- Cylinder Brush Capabilities

- ...and more

Chapter 1: Understanding Cylinder Brushes

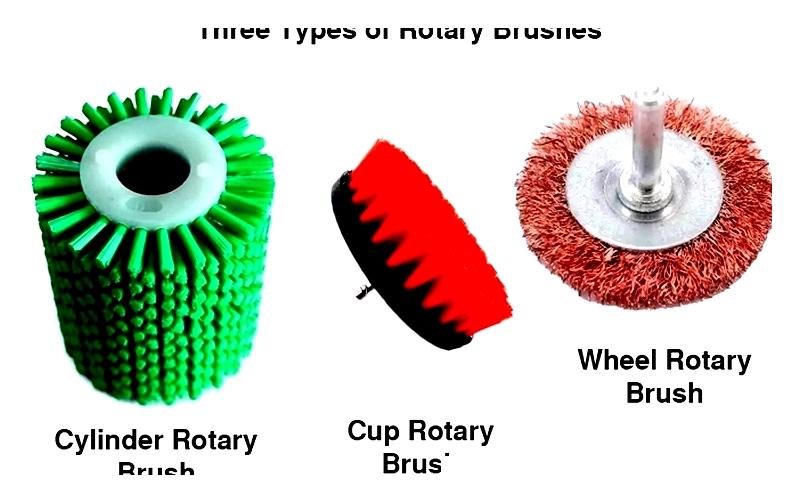

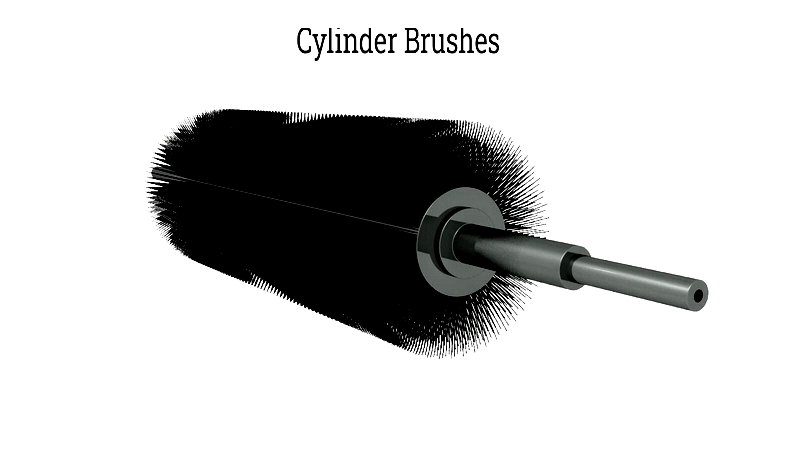

Commonly referred to as "coil brushes," "rotary brushes," or "spiral brushes," cylinder brushes are made by wrapping a metal strip around a cylindrical rod (mandrel) until the desired brush diameter is achieved.

These brushes typically feature bristles made from various materials, including flexible synthetics, soft natural fibers, metal wires, and durable lightweight polymers. The bristles are secured through stapling, gluing, or knotting and positioned perpendicularly through drilled holes in the mandrel. A central arbor hole allows attachment to a shaft, enabling motor-driven rotation. The construction method varies based on factors like bristle count, operating RPM, and other specifications.

Materials for Cylinder Brush Fill

The term "fill material" refers to the bristle substance used on the brush's exterior. Different materials offer unique advantages for various applications. Below are some popular fill materials and their benefits.

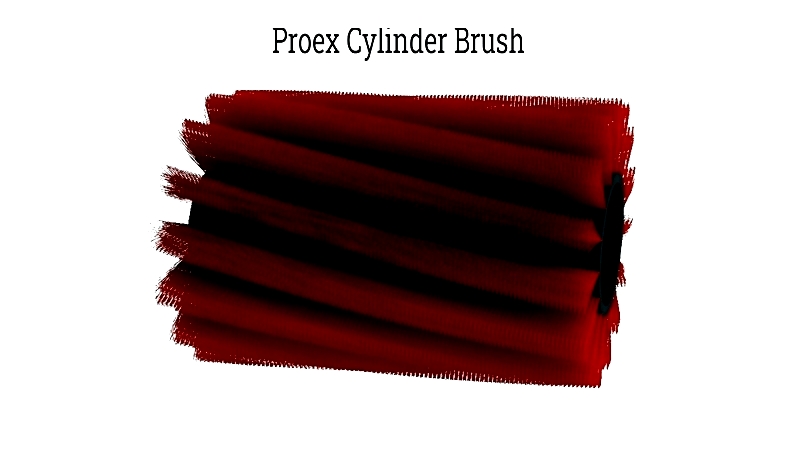

Proex®: Made from synthetic resin polypropylene, Proex features an X-shaped filament that increases the effective cleaning surface by about 25% compared to standard polypropylene. It excels in both indoor and outdoor environments, including wet conditions, and is highly durable. However, it's unsuitable for high-temperature applications like foundries.

Polypropylene: This synthetic thermoplastic polymer offers excellent chemical and fatigue resistance, performing reliably indoors and outdoors, even in humid conditions. While not ideal for high temperatures, it works well in freezing conditions and effectively collects larger particles. Its wear life is impressive.

Nylon: Less aggressive than polypropylene, nylon is less effective in damp conditions but suitable for rugged outdoor surfaces or high-temperature environments (up to 150°C). It's ideal for foundries and offers excellent durability.

Organic Fiber: Natural fibers wear faster than synthetics but excel at cleaning fine debris and controlling light dust. They're unsuitable for damp floors but work well for carpet sweeping without creating static electricity.

Goat Hair: Exceptionally soft and fine, goat hair is perfect for delicate brushes used in electronics.

Horsehair: Ideal for gentle dusting, cleaning, and polishing.

Wire & Polymer: Wire provides gentle cutting for hardened dirt, while polymer enhances sweeping. These brushes have limited wear life but excel in dust management.

Wire and Proex®: This combination offers Proex's versatility with wire's cutting action for general sweeping and removing hard-packed dirt. Note: Wire brushes are prohibited in food manufacturing and airports. The wire wears out before Proex, but overall durability is reasonable.

PBT Polyester: More expensive than nylon, polyester is stiffer, performs better in wet conditions, and offers excellent durability. Large-diameter filaments (over 0.8mm) begin to wear after about 120 hours of use.

Chapter 2: Types of Cylinder Brushes

Cylinder brushes, also known as rotary or roller brushes, are essential industrial tools used in manufacturing, food processing, material handling, and surface treatment. They're versatile, appearing in automated machinery, industrial vacuums, car washes, and production lines. Their design flexibility—from dense fills to spiral patterns—makes them suitable for heavy-duty cleaning or delicate handling. Easy to mount on shafts, they simplify maintenance.

This chapter explores common cylinder brush types, their designs, and ideal applications. Understanding these distinctions helps you choose the right brush for your needs.

Epoxy Wound Brushes

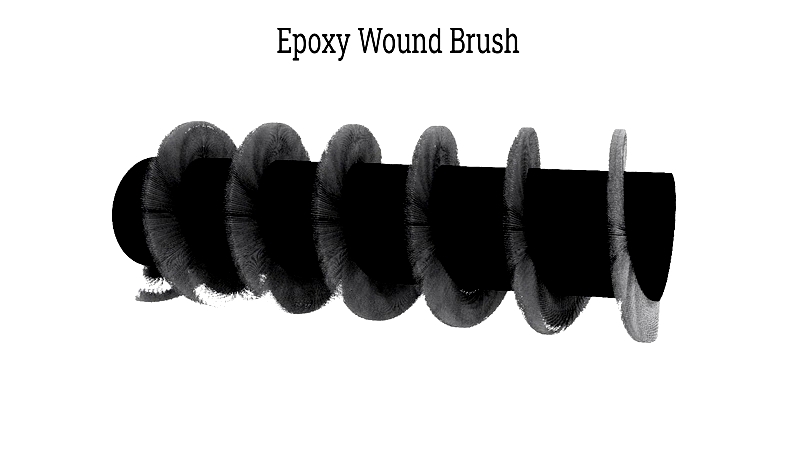

Epoxy wound brushes offer unmatched flexibility and durability for high-speed (RPM) applications requiring precise balancing. They feature a steel, aluminum, brass, stainless steel, or plastic core with a helical groove to anchor filaments. Stainless steel wires secure the filaments, allowing for smaller diameters and efficient refilling.

Ideal for high-speed conveyor cleaning, polishing, and deburring, these brushes provide uniform contact. The bristle material depends on the application—for example, metal filaments for deburring. They're preferred in automotive, aerospace, food processing, and metalworking industries.

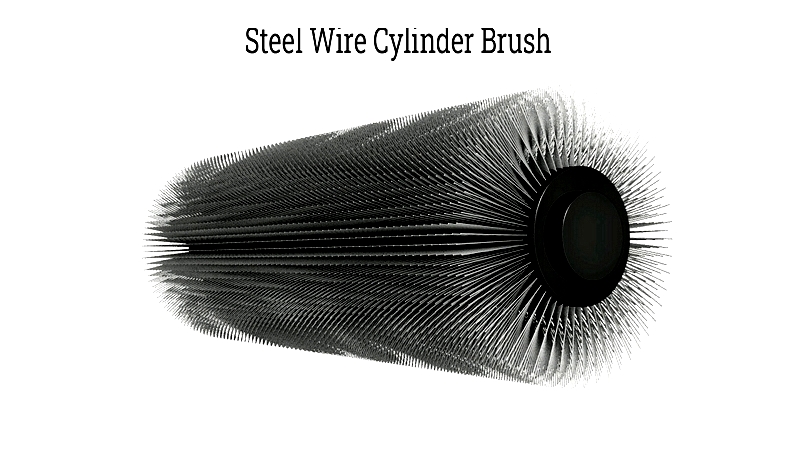

Steel Wire Cylinder Brushes

Steel wire brushes offer superior fatigue life and cutting action at an economical price. They excel at aggressive debris removal, descaling, paint stripping, and rust removal on robust surfaces like steel, iron, and conveyor belts. Softer filaments are better for delicate surfaces.

Heat and Moisture Resistance: These brushes tolerate temperatures up to 275°F briefly but aren't suited for continuous high humidity or corrosive environments. For such conditions, consider stainless steel or brass brushes. Modern steel brushes can be customized for density, diameter, and size.

Common uses include:

- Conveyor cleaning in manufacturing and packaging

- Bakery conveyor scrubbing

- Heavy-duty scrubbing and degreasing

- Material handling system maintenance

- Non-abrasive metal parts cleaning

- Satin finishing of aluminum

Steel wire brushes remain a top choice for rust removal and aggressive cleaning.

Stainless-Steel Wire Cylinder Brushes

Stainless-steel brushes are ideal for corrosion-resistant and hygienic environments. They clean, deburr, or finish stainless steel and non-ferrous metals without rust contamination. Used in food processing, pharmaceuticals, and commercial kitchens, they withstand water, humidity, and chemicals.

Stainless steel handles temperatures up to 600°F, making it suitable for high-heat processes and sterilization. Specialty alloys like Inconel® are used for extreme temperatures. Choose stainless steel for food compliance and harsh chemical environments.

Brass Wire Cylinder Brushes

Brass wire brushes feature softer bristles, making them ideal for cleaning and polishing softer metals without scratching. Made from Alloy 260 (70% copper, 30% zinc), they're non-sparking and conductive, suitable for hazardous environments and static reduction.

Brass brushes operate up to 300°F and are used for surface roughening, conveyor maintenance, and static dissipation. They're common in energy, electronics, and aerospace industries.

Primary applications:

- Industrial conveyor maintenance

- Surface roughening for adhesion

- Material-handling equipment cleaning