Introduction

This is the internet's most comprehensive guide to check valves.

You'll discover:

- What a Check Valve Is

- Different Types of Check Valves

- Common Applications of Check Valves

- How Check Valves Operate

- And much more...

Chapter One – Understanding Check Valves

A check valve acts as an automatic safety device designed to permit unidirectional flow of fluids and gases while preventing reverse movement. When pressure is applied, fluids enter through the inlet, causing the disc to lift from the valve seat and enabling discharge through the outlet.

Flow continues while sufficient pressure keeps the disc open. When pressure decreases, the disc automatically returns to its seat, stopping the flow.

The required pressure to open the valve is called cracking pressure, ranging from 3 psi to 350 psi depending on the valve's size, purpose, and design.

Check valves ensure proper flow direction while creating tight seals to prevent leaks. By controlling liquid flow, they help protect pumps and compressors from potential damage.

Check valves have various names depending on their application and design, including clack, non-return (NRV), reflux, retention, and one-way valves. Despite their simple design, these valves are crucial for protecting pumps, piping systems, and fluid control.

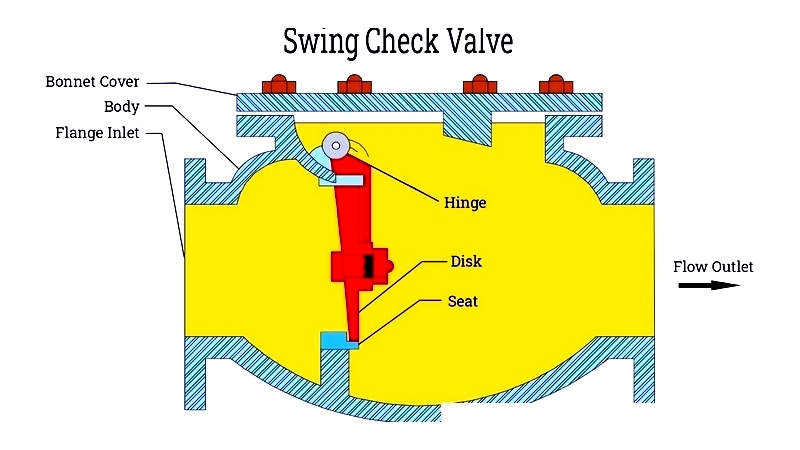

The swing check valve, shown below, is the most common type. Its full port design allows complete disc retraction during flow. The disc opens with the flow direction and stays open during continuous flow. When flow decreases or stops, gravity helps close the disc.

Check valves primarily prevent reverse flow that could damage pumps and other components. Valve closure may cause water hammer, where fluid forcefully hits the closed valve. Therefore, check valves must be durable and made from high-quality materials to withstand these forces.

Check valves can be noisy and may require noise reduction measures. Various control strategies, including springs, levers, or weights, help manage pressure surges and prevent sudden closure.

Chapter Two – Types of Check Valves

Check valves are vital components in piping systems that automatically prevent fluid or gas backflow. These one-way valves protect pumps, compressors, and process lines across various industries. Available in multiple designs, they serve applications from water treatment to aerospace, ensuring operational safety.

While all check valves share the same basic function—permitting unidirectional flow—selection depends on factors like flow rate, media type, temperature, pipe size, pressure differential, installation orientation, and flow velocity. Understanding these factors helps engineers choose the right valve for reliability and minimal maintenance. The following chart shows recommended check valves for different scenarios.

Check Valve Varieties

Selecting the right check valve is crucial for efficient and safe fluid handling. Key considerations include media type, pipe diameter, pressure gradient, maintenance needs, and installation orientation. Additional factors like cracking pressure, material compatibility, and operational environment should also be evaluated.

Check valves range from standard designs to highly specialized configurations. Technological advancements, such as anti-water hammer features, continue to expand options. While challenging to categorize every variant, most share common characteristics like unidirectional flow, low maintenance, and material versatility.

Below are the most common check valve designs, each offering unique benefits for specific applications. Understanding these differences helps users make informed decisions.

Swing Check Valves

A swing check valve is a classic self-activating non-return valve. Its hinged disc swings open with forward flow and closes against backflow. These valves are valued for minimizing turbulence and maintaining low pressure drops.

Lever and weight designs suit systems prone to water hammer, while spring-assisted versions excel in high-pressure applications. Regular maintenance ensures reliable operation.

Wafer Check Valves

Wafer check valves feature compact, lightweight designs with pivoting discs. They're ideal for tight spaces and handle solids well, making them popular in water treatment and food processing.