Introduction

This article provides an in-depth exploration of mattress bags.

You'll discover information on various topics including:

- What is a Mattress Bag?

- Materials Used to Make Mattress Bags

- Types of Mattress Bags

- Benefits of Mattress Bags

- How to Choose a Mattress Bag

- And Much More...

Chapter One – What is a Mattress Bag?

A mattress bag is a durable plastic covering designed to protect mattresses from environmental factors like dirt, dust, moisture, and damage. Available in various sizes and styles, these bags accommodate different mattress specifications. Constructed from plastic materials with thickness options ranging from 1 mil to over 5 mil, they effectively safeguard both mattresses and box springs.

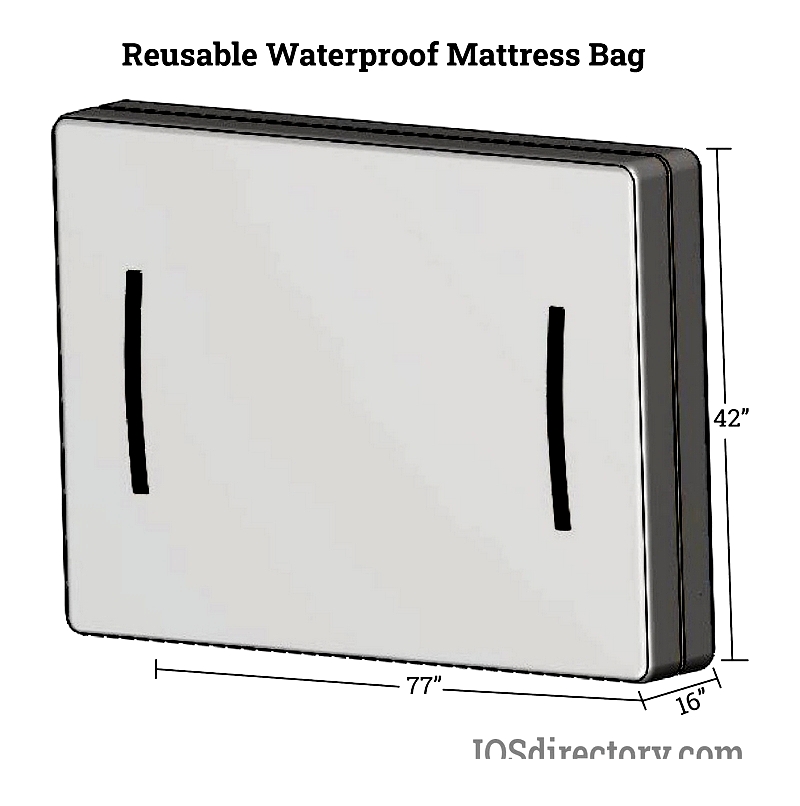

Premium mattress bags are made from polyethylene, offering waterproof and tear-resistant properties. They feature #10 heavy-duty zippers that close securely and operate smoothly without snagging. Additionally, these high-quality bags include four stitched handles on each side for easy transport. Despite their size, mattress bags can be folded or rolled for compact storage.

Chapter Two – What Materials Are Used to Make Mattress Bags?

Traditionally, mattresses were transported by placing them on clean cloth or plastic in moving vehicles. While common, this method risks exposing mattresses to dirt, weather conditions, stains, and potential damage.

When delivered from manufacturers or stores, mattresses come wrapped in tightly sealed plastic that's discarded after arrival. This protective wrapping demonstrates the commitment of retailers and producers to product quality and customer satisfaction.

As moving practices evolved, the risks of unprotected mattress transport became more evident. While manufacturers have long recognized these issues, consumer awareness about protecting mattresses during moves has only recently increased.

This growing awareness has boosted demand for durable mattress bags. Manufacturers now produce stronger, more resilient options using high-quality polymers. Modern choices include antimicrobial covers, waterproof bags, breathable fabrics, and reusable storage solutions that minimize dust mites, allergens, and moisture exposure during transport or storage.

Mattress Bag Materials

Mattress bags utilize various materials depending on their purpose and performance needs. Categories include heavy-duty transport bags, lightweight protectors, and durable waterproof options. When selecting a mattress moving bag or storage bag, consumers consider thickness (in mils), tear resistance, breathability, and closure types.

All plastic bags are created through polymer blending processes that produce different plastic grades and thicknesses. These material advancements ensure optimal protection against dirt, pests, humidity, and physical impacts.

Polyurethane (PU) Material

Polyurethane is a versatile plastic that can be solid or film-like. This flexible elastomer offers adjustable properties, making it ideal for high-grade mattress bags. Its tear resistance, flexibility, and waterproof sealing capabilities are crucial for preserving mattress quality.

Developed during WWII as a rubber substitute, polyurethane's durability made it popular for aircraft protection. Post-war applications expanded to include mattress bags, foam rubbers, and various other products.

Produced by reacting diisocyanates with polyols, polyurethane mattress bags often use CO₂ as a blowing agent. Marketed as hypoallergenic and mildew-resistant, these premium options appeal to consumers seeking long-term storage solutions.

Polypropylene (PP) Materials

Polypropylene, a thermoplastic polymer, forms the basis of many plastic fabrics. This strong, chemical-resistant plastic is commonly used for mattress bags due to its high melting point and stress resistance.

Its durability makes polypropylene ideal for mattress protection, offering affordable solutions for both commercial and residential use. The material's lightweight yet tough construction accommodates various mattress sizes while resisting everyday wear.

Polyethylene or Polyethene

Polyethylene is widely used in packaging, including mattress bags. Available in high, medium, and low densities, this waxy-textured plastic offers excellent impact resistance.

Consumers choose heavy-duty polyethylene mattress bags for their puncture and water resistance. Low-density options provide budget-friendly protection, while clear polyethylene allows for product visibility without contamination risk. The material's vacuum-sealing compatibility enables compact storage.

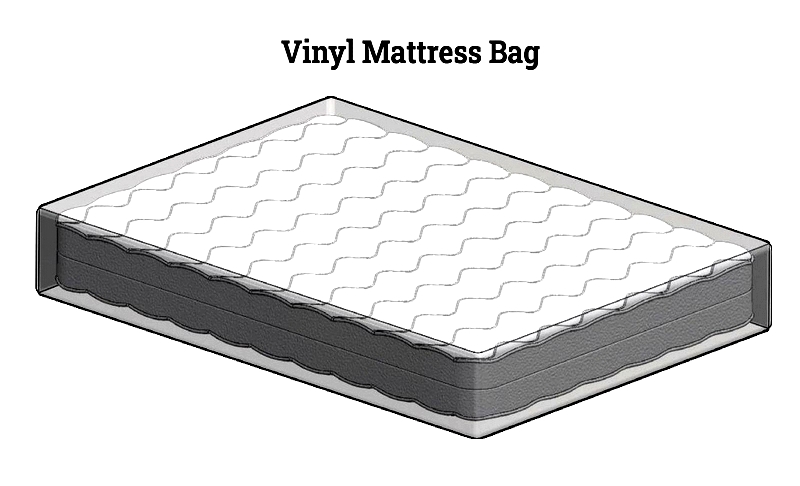

Vinyl – Polyvinyl Chloride (PVC)

Developed in the 1920s, PVC combines ethylene and chlorine to create a moisture-resistant, durable material. Available in various thicknesses and colors, vinyl is popular for mattress covers.

Its antibacterial properties make PVC bags ideal for healthcare and hospitality settings. Reinforced seams enhance protection for premium mattresses, while resealable designs offer long-lasting security.

Cotton Canvas

Cotton canvas offers durable, eco-friendly mattress protection. These washable bags feature built-in handles and often include zippered closures. Their breathable design prevents moisture buildup, reducing mold and mildew risks.

As sustainability concerns grow, natural fiber options like organic cotton are gaining popularity among environmentally conscious consumers. These alternatives provide plastic-free solutions for mattress protection during moves or storage.