Introduction

This section provides information about plastic coatings and dip molding, along with a list of leading manufacturers.

- Overview of Plastic Coatings and Dip Molded Plastics

- Various Types of Coating and Molding Polymers

- Plastic Coating Production Processes

- Machinery for Dip Molding and Dip Coating

- Additional related topics...

Chapter 1: Understanding Plastic Coatings and Dip Molded Plastics

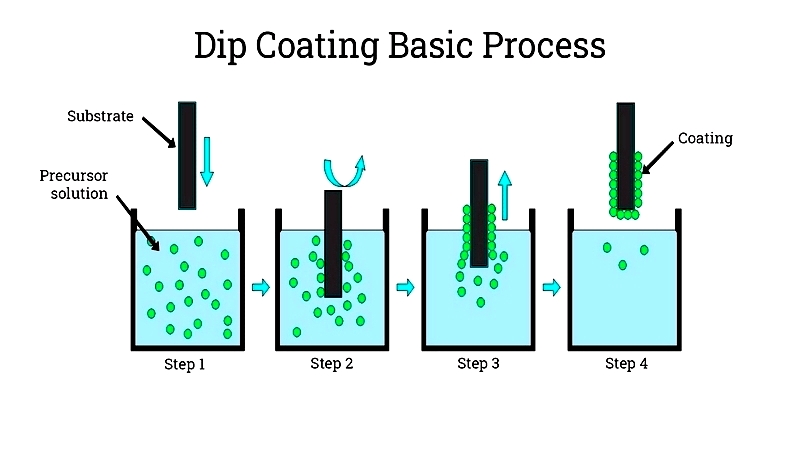

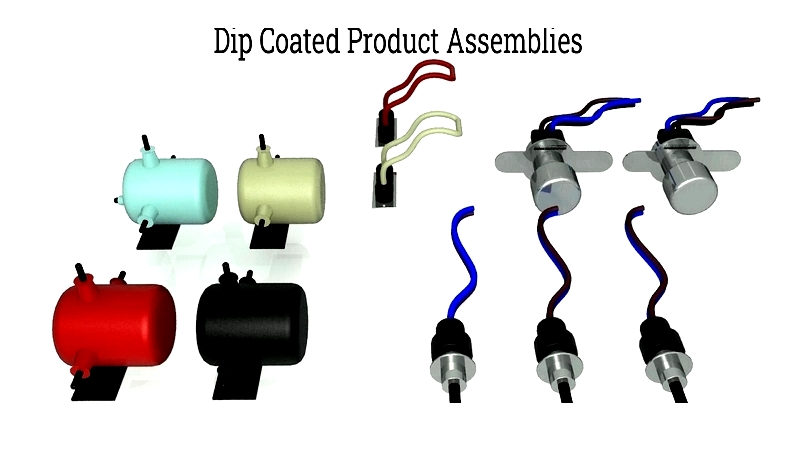

Plastic coating applies liquid polymers or plastics to components through dipping or immersion methods. This process creates a durable plastic layer that offers both protection and aesthetic enhancement. It significantly improves material resistance to scratches, abrasions, corrosion, and environmental wear. By reinforcing metal parts, plastic coatings extend their service life while providing functional benefits like better grip and electrical insulation.

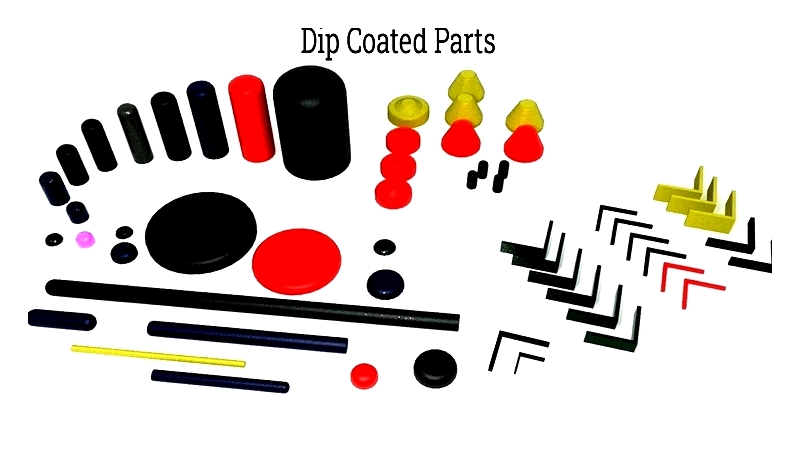

Plastic coatings are commonly found on hand tools, grips, and handles. For instance, pliers often feature plastic-coated handles that enhance user comfort and durability. These coatings also benefit various other products by providing additional strength and protection, including shopping carts, baskets, forceps, covers, caps, and plugs.

Plastic coatings serve as effective thermal and electrical insulators. They're frequently applied to hand tools like tongs and spatulas for safe handling of hot objects. In electronics, these coatings insulate components such as wires, cables, and meter probes.

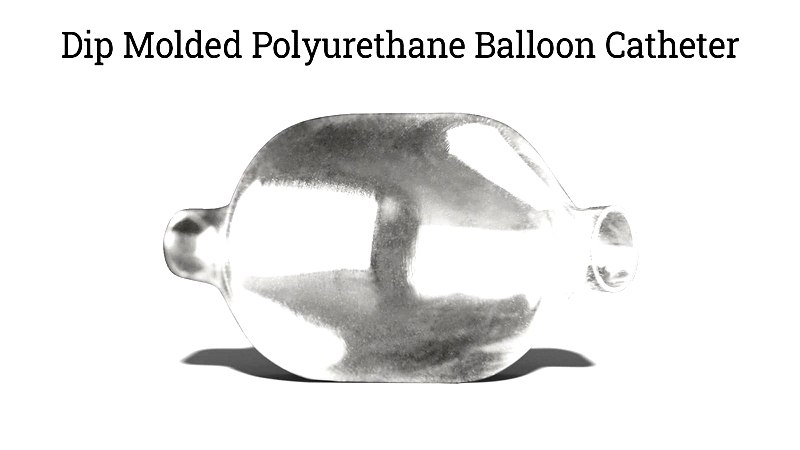

Dip molding attaches plastic coatings to metal items by using the component as a mold. The process involves treating and heating the metal before immersing it in liquid polymer. As the polymer cools, it forms a durable plastic layer on the metal surface.

Dip molding resembles dip coating but includes an additional step for part removal. This method produces hollow, single or double-walled components while minimizing secondary processes like trimming. Common dip molded products include latex gloves, accessories, cups, and sports equipment components.

Chapter 2: Polymer Types for Coating and Molding Processes

Selecting appropriate polymers for coating and molding ensures optimal durability, finish, and performance. Common options include plastisol, latex, neoprene, polyurethane, and epoxy. These thermoplastic and thermosetting resins offer distinct advantages based on their chemical properties. Key characteristics include liquid state at room temperature for easy processing, proper viscosity for even application, and suitable surface tension to prevent dripping during curing.

Plastisol

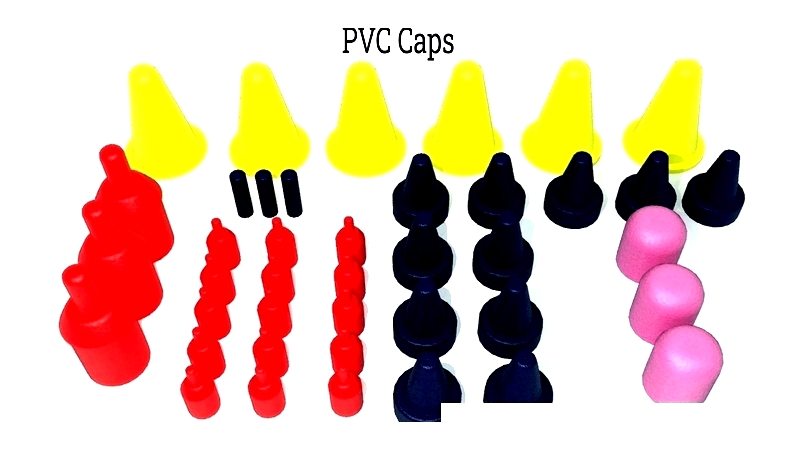

Plastisol, a PVC-based suspension in plasticizer, transforms into flexible material when heated. Valued for durability, corrosion resistance, and impact strength, it's ideal for electrical insulation and protective coatings. Customizable with colorants and additives, plastisol suits tool grips, PVC caps, and medical components.

Latex

Latex offers elasticity and tear resistance for products like gloves, balloons, and tubing. While versatile, allergy concerns have prompted alternatives like nitrile and neoprene in sensitive applications.

Neoprene

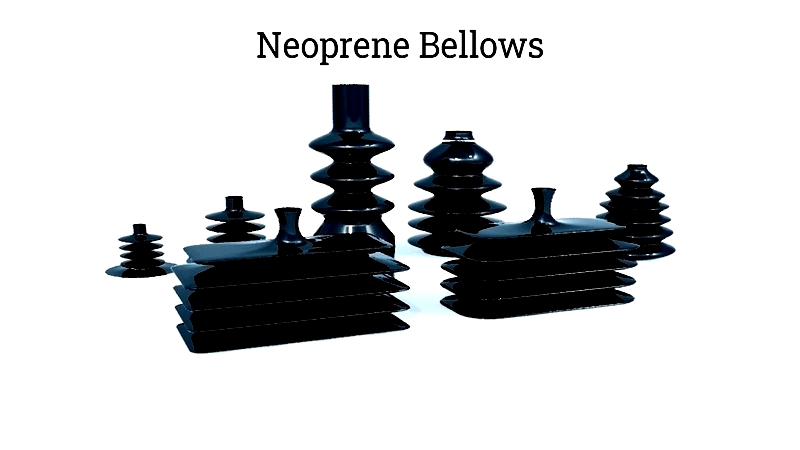

Neoprene excels in chemical resistance and temperature stability, making it suitable for automotive components, gaskets, and medical devices. Its non-allergenic properties enhance safety in industrial applications.

Polyurethane

Polyurethane provides abrasion resistance and flexibility for medical tubing, automotive seals, and industrial liners. Its customizable properties allow both rigid and flexible product manufacturing.

Epoxy

Epoxy delivers superior adhesion and chemical resistance for electrical insulation, industrial equipment, and aerospace components. Its dense structure ensures long-term protection in demanding environments.

Selecting the Right Polymer

Consider application requirements, chemical compatibility, and environmental factors when choosing polymers. evaluate cost, processability, and customization options to meet specific project needs. Consult suppliers for technical guidance and material samples.

For detailed product information, contact polymer suppliers to ensure optimal performance and compliance with your project specifications.