Introduction

This article provides an in-depth exploration of RF shielding.

Continue reading to learn about key topics including:

- What RF shielding is

- The nature of radio frequency interference

- Materials used for RF shielding

- Common RF shielding applications

- And more…

Chapter 1: What is RF Shielding?

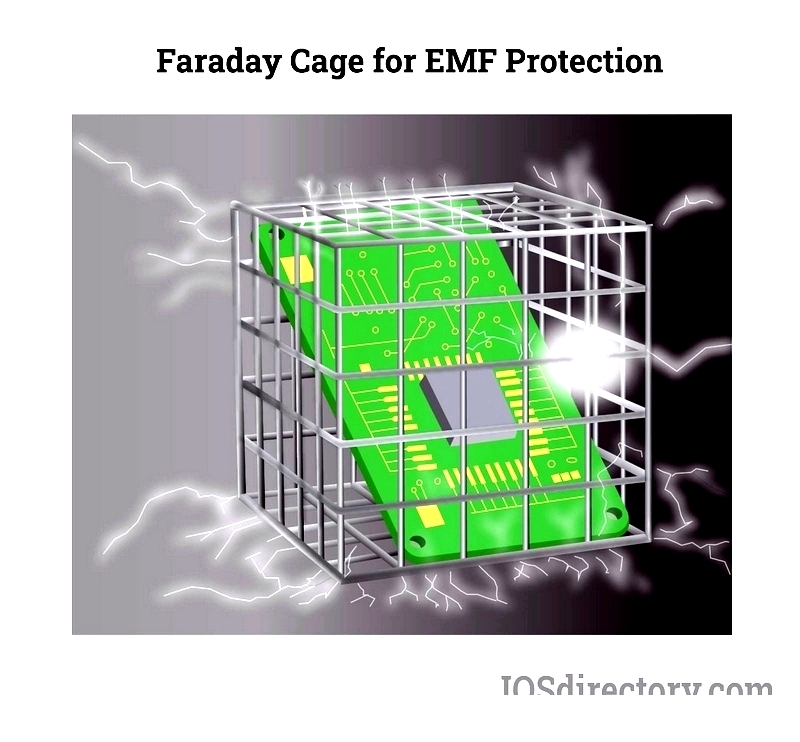

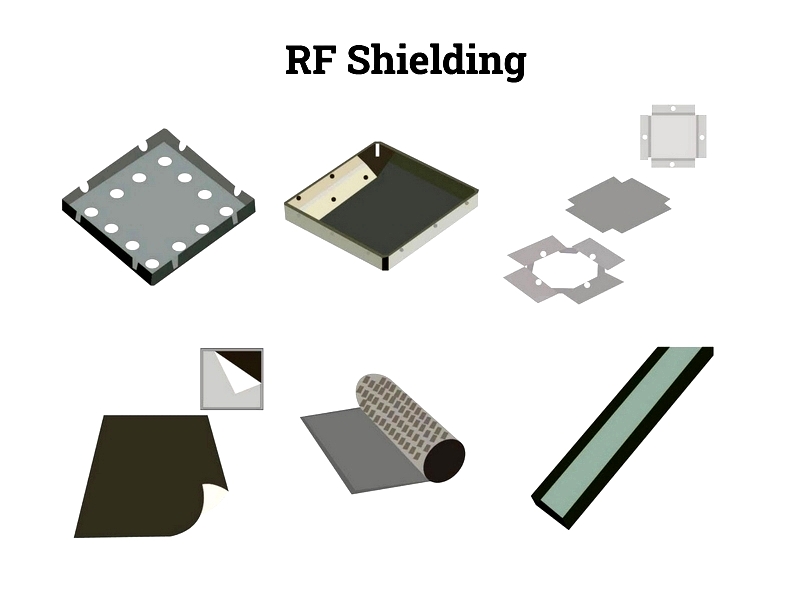

RF shielding, also known as radiofrequency shielding, involves preventing electromagnetic signals from causing radio frequency interference (RFI) that disrupts electronic devices. This is achieved by enclosing electronic components, wiring, and electromagnetic field sources/receivers with barriers made of conductive and magnetic materials. The main objective is to isolate these elements from external interactions. RF shielding effectiveness depends on multiple factors, including material properties, design, thickness, signal frequency, and any shield openings.

Radiofrequency interference (RFI) can significantly impact electronic and communication devices, potentially causing malfunctions, data loss, security vulnerabilities, or complete device failures. While RFI remains unavoidable in modern electronics, RF shielding serves as an effective solution to protect devices from its harmful effects.

Chapter 2: The Nature of Radio Frequency Interference

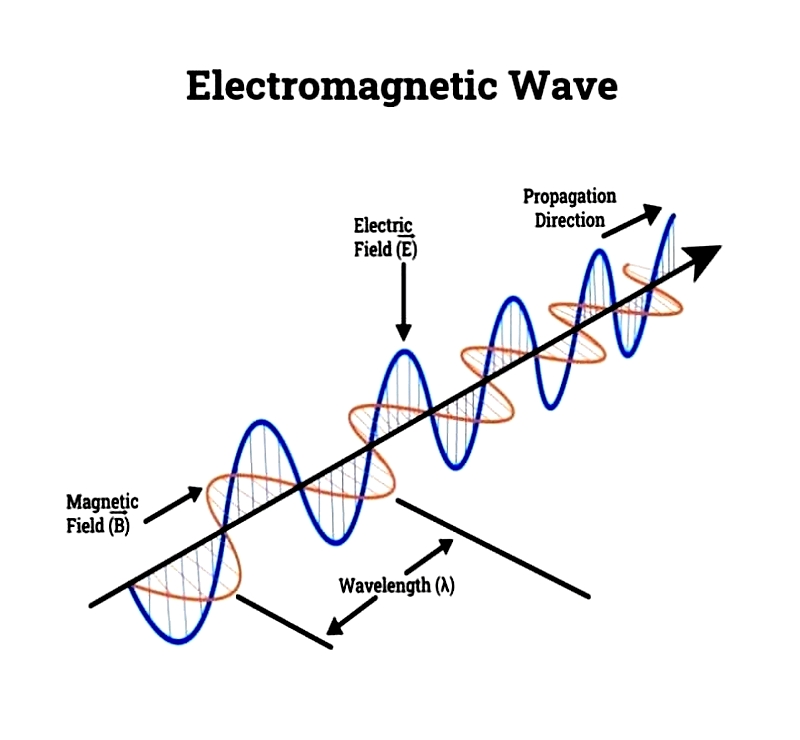

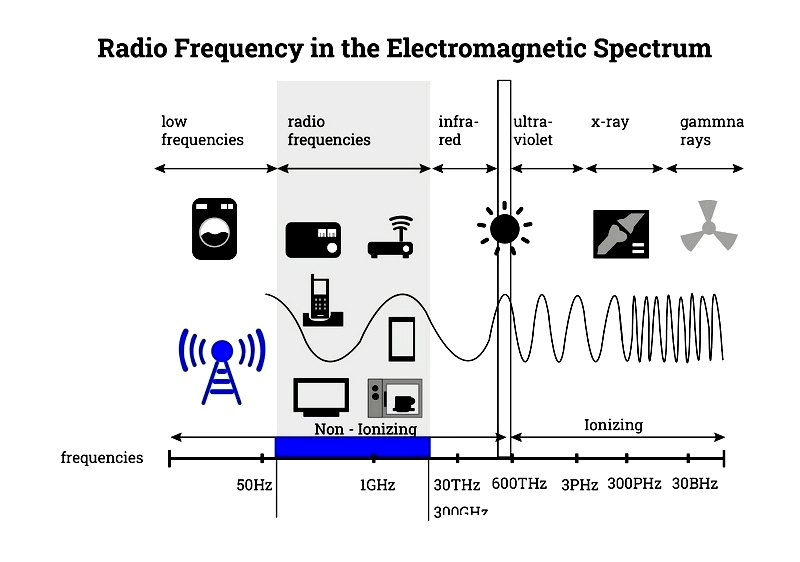

Electromagnetic waves are essential for wireless communications and electronic devices. They carry energy through oscillating electric and magnetic fields perpendicular to each other. Characterized by wavelength and frequency, these waves span the electromagnetic spectrum from extremely low frequencies (ELF) to gamma rays. The radio frequency (RF) portion is particularly important for modern electronics and data transmission systems.

Electromagnetic Interference and Radio Frequency Interference

Electromagnetic interference (EMI) refers to unwanted electromagnetic signals that disrupt electrical equipment operation. Often called "electromagnetic noise," EMI presents challenges in environments with sensitive equipment like medical devices, industrial systems, and telecommunications infrastructure. The key difference between EMI and radiofrequency interference (RFI) lies in their frequency ranges.

While EMI can occur across the entire electromagnetic spectrum, RFI specifically involves interference within the radio frequency range (3 kHz to 300 GHz). This range includes technologies like AM/FM radio, Wi-Fi, cellular networks, and Bluetooth. Understanding RFI is therefore crucial for maintaining device functionality and meeting regulatory requirements in wireless technology fields.

Types of Radio Frequency Interference

RFI can be classified by its source, duration, and bandwidth. Recognizing these categories helps in developing effective shielding and filtering solutions.

Source

Natural Sources

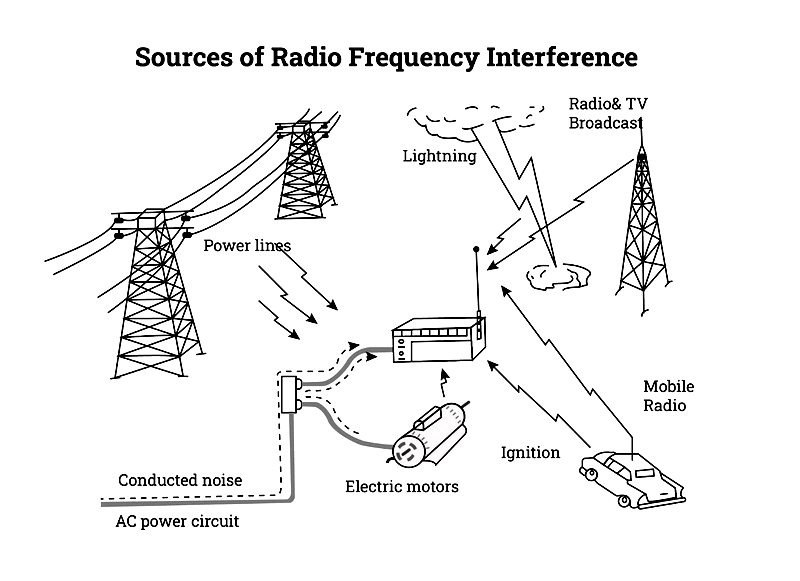

Natural RFI originates from astronomical events like lightning, solar flares, and cosmic noise, along with environmental phenomena such as static electricity and auroras. These create background RF noise affecting radio astronomy, GPS, and satellite communications.

Man-Made Sources

Electronic devices generate artificial electromagnetic radiation that may interfere with other equipment. Man-made RFI sources fall into two categories:

-

Unintentional Sources Devices like electric motors, lighting systems, industrial machinery, and modern electronics with wireless connectivity can inadvertently emit electromagnetic radiation. High-speed digital electronics particularly increase RFI risks as clock speeds rise.

- Intentional Sources Equipment designed to emit RF energy, including radars, radio transmitters, and broadcasting antennas, serve essential functions in telecommunications, navigation, and electronic warfare.

Duration

Continuous RFI involves steady signal emission from sources like power lines or high-frequency oscillators. Impulse RFI occurs intermittently from switching events, arcing, or electrical transients, potentially causing signal degradation or data loss.

Bandwidth

RFI bandwidth describes the affected frequency range, which influences shielding and filtering solutions.

Narrowband

Narrowband RFI affects specific frequencies, often caused by oscillators or malfunctioning components. It can impact radio receivers, medical devices, and GPS systems, requiring targeted mitigation.

Broadband

Broadband RFI spans multiple frequencies, typically from non-linear processes or industrial equipment. Effective shielding and filtering are essential, especially in critical sectors like aerospace and defense.

Coupling Mechanisms

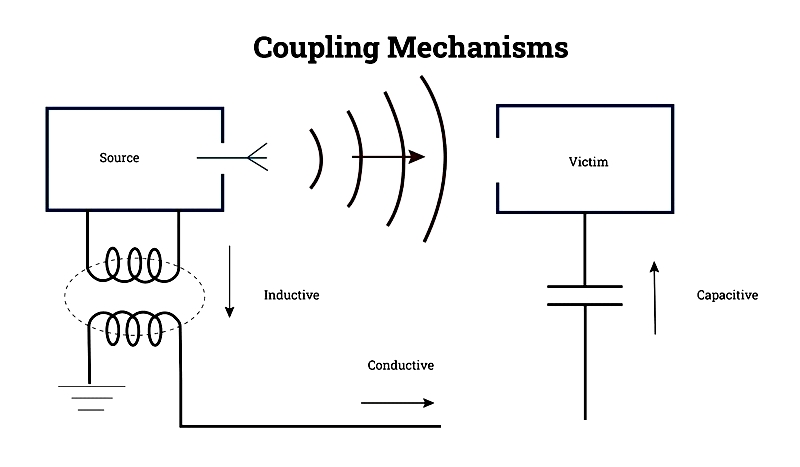

Understanding how RFI transfers to affected devices helps in designing mitigation strategies. The primary mechanisms include:

Radiation Coupling

Electromagnetic waves travel through air from source to receiver, particularly challenging in environments with multiple wireless devices.

Conduction Coupling

RFI travels along physical connections like wiring, making cable shielding and proper grounding essential.

Capacitive Coupling

Electric field transfer affects nearby circuits, requiring careful PCB design and insulation.

Magnetic Coupling

Fluctuating magnetic fields induce RFI in conductor loops, addressed through twisted-pair cabling and magnetic shielding.

Why RFI Management Matters

With growing wireless technologies and IoT devices, effective RFI control ensures regulatory compliance and protects device reliability. Implementing proper shielding, filtering, and design practices prevents data loss and extends equipment lifespan, making RFI understanding crucial for product evaluation and procurement decisions.