Introduction

This article provides an in-depth examination of plastic pallets.

Continue reading to explore key topics including:

- What plastic pallets are

- The benefits of plastic pallets

- Materials and manufacturing methods for plastic pallets

- Different types of plastic pallets

- Standard plastic pallet sizes

- And much more...

Chapter 1: What Are Plastic Pallets?

Plastic pallets are robust platforms designed to support large quantities of goods during handling processes while maintaining product integrity. These processes include lifting, moving, stacking, storing, and transporting goods over short or long distances by land or sea. For easier transportation, plastic pallets are designed to work seamlessly with equipment like forklifts, pallet jacks, and front loaders.

Pallets can be made from various materials, including metal, plastic, wood, or paper. Compared to alternatives, plastic pallets offer advantages such as being lightweight, hygienic, and cost-effective. Businesses can choose from multiple plastic pallet designs tailored to their specific needs. You'll find plastic pallets in warehouses, factories, retail stores, and transportation companies. All pallet types play a vital role in logistics and supply chain operations.

Plastic pallets follow standardized dimensions set by regional regulations to prevent delays and complications during cross-regional transfers. These standards also apply to pallets made from other materials.

Chapter 2: Advantages of Plastic Pallets

Plastic pallets offer numerous benefits for supply chain operations:

Plastic pallets resist microbial growth and pests

A key advantage of plastic pallets—especially for food, beverage, pharmaceutical, and medical industries—is their resistance to microbial growth and pests. Their non-porous, smooth surface and moisture resistance prevent the growth of pathogens, bacteria, fungi, and mold, which can spoil perishable goods or pose health risks.

Because plastic pallets are inhospitable to pests, they are ideal for hygienic logistics, cold storage, grocery distribution, and other applications requiring compliance with food safety standards like FDA, HACCP, or GFSI.

Plastic pallets are exempt from ISPM No. 15

Plastic pallets are not subject to the International Standards for Phytosanitary Measures No. 15 (ISPM-15), which regulates wood packaging in international trade to prevent the spread of invasive species. Wooden pallets must undergo approved treatments and display an IPPC mark to show compliance.

Since plastic pallets don't require these treatments, they reduce shipping delays, administrative costs, and compliance burdens for international logistics.

Plastic pallets resist contamination, odors, and corrosion

Plastic pallets remain unaffected by spills, cleaning agents, chemicals, and moisture. Their non-absorbent nature prevents odor retention and cross-contamination, making them easy to clean and sanitize. This makes them suitable for transporting chemicals, pharmaceuticals, fresh produce, meats, dairy, and hazardous materials while meeting sanitary transport requirements.

Plastic pallets are lightweight

Plastic pallets are easier to handle and transport than wooden or metal pallets due to their lighter weight. This reduces shipping costs, fuel consumption, and carbon emissions, particularly in airfreight. Their ergonomic design also minimizes workplace injuries and streamlines warehouse operations.

Plastic pallets are durable

Constructed as single solid pieces through molding, plastic pallets lack weak spots found in mechanically fastened pallets. They resist impact, splintering, and water absorption, making them ideal for closed-loop systems, automated handling, and high-cycle applications. Their durability lowers long-term ownership costs.

Plastic pallets are reusable and long-lasting

Plastic pallets outlast wooden pallets and can be reused many times in supply chains, warehouses, and distribution centers. Nestable or stackable designs optimize storage and support sustainability goals by reducing operational expenses.

Plastic pallets are recyclable

Many plastic pallets incorporate recycled materials, lowering production costs and environmental impact. At end-of-life, they can be recycled into new pallets or products, supporting waste reduction and circular economy initiatives.

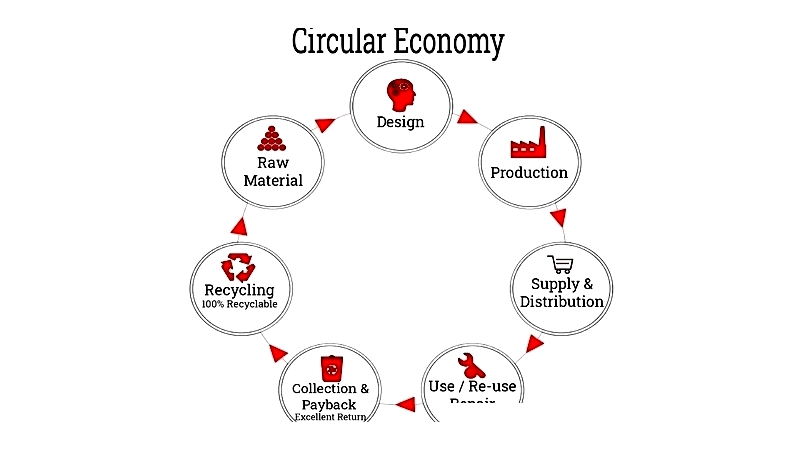

Sustainability and the Circular Economy

Plastic pallets align with modern sustainability goals by being recyclable and reusable. They help companies reduce environmental impact and meet ESG (Environmental, Social, and Governance) objectives while improving supply chain efficiency.

As part of returnable transport packaging (RTP), plastic pallets contribute to closed-loop logistics, minimizing waste and enhancing resource efficiency.

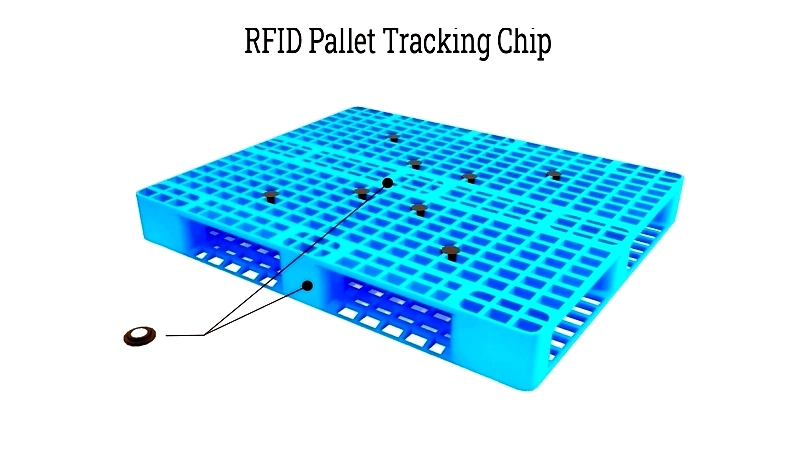

Technological Advancements in Inventory Control

To improve inventory management, plastic pallets can integrate technologies like RFID, IoT sensors, and GPS for real-time tracking, automated stock-taking, and warehouse system integration. These smart pallets enhance logistics efficiency and support Industry 4.0 initiatives.

Smart pallets enable better inventory accuracy, predictive maintenance, and streamlined supply chain processes.

Cost Considerations and Limitations of Plastic Pallets

Some drawbacks of plastic pallets include:

- Difficulty in repairing damaged pallets

- Higher initial cost compared to wooden pallets

While plastic pallets have a higher upfront cost, their long-term benefits—such as reusability, reduced maintenance, and hygiene—often justify the investment. However, wooden pallets may be more cost-effective for single-use or high-loss-risk shipments. Businesses should evaluate their specific needs when choosing pallet types.