Introduction

This article provides an in-depth exploration of compression molding.

You'll gain comprehensive knowledge on the following aspects:

- The fundamentals of compression molding

- The compression molding process

- Different types of compression molds

- Technological advancements in compression molding

- Comparing compression molding with other molding techniques

- Practical applications of compression molding

- Materials suitable for compression molding

- Benefits of compression molding

- Industry standards for compression molding

- And additional relevant information

What is Compression Molding?

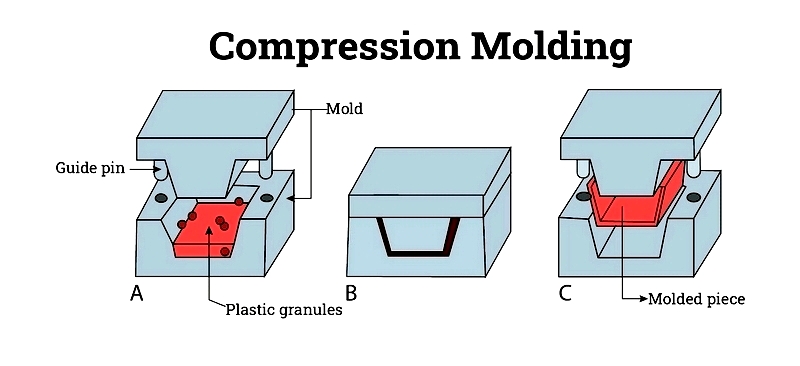

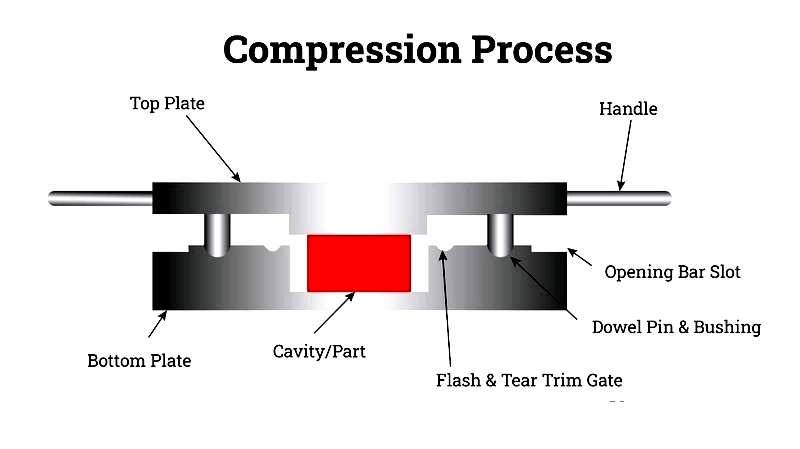

Compression molding is a versatile manufacturing process that uses compressive force to shape materials within a two-part mold. The mold consists of upper and lower sections that form a cavity when compressed, creating the desired product shape. The design allows for easy removal of the finished product after setting and curing.

While initially developed for synthetic materials, compression molding remains the most cost-effective method for processing thermosetting plastics. Thermoplastics, however, are typically better suited for injection molding.

Common compression mold types include flash, positive, landed positive, and semi-positive molds, with flash molds being the most widely used. The process can be divided into bulk and sheet molding. Bulk molding combines various components like fillers, catalysts, stabilizers, pigments, and fiber reinforcements. Key advantages of compression molding for thermoset plastics include enhanced strength, lighter weight, and superior corrosion resistance.

The Process of Compression Molding

Compression molding offers a durable and economical manufacturing solution.

Unlike disposable molds, compression molds are built to withstand multiple production cycles.

Below is a detailed breakdown of the compression molding process:

Mold Preheating or Preparation

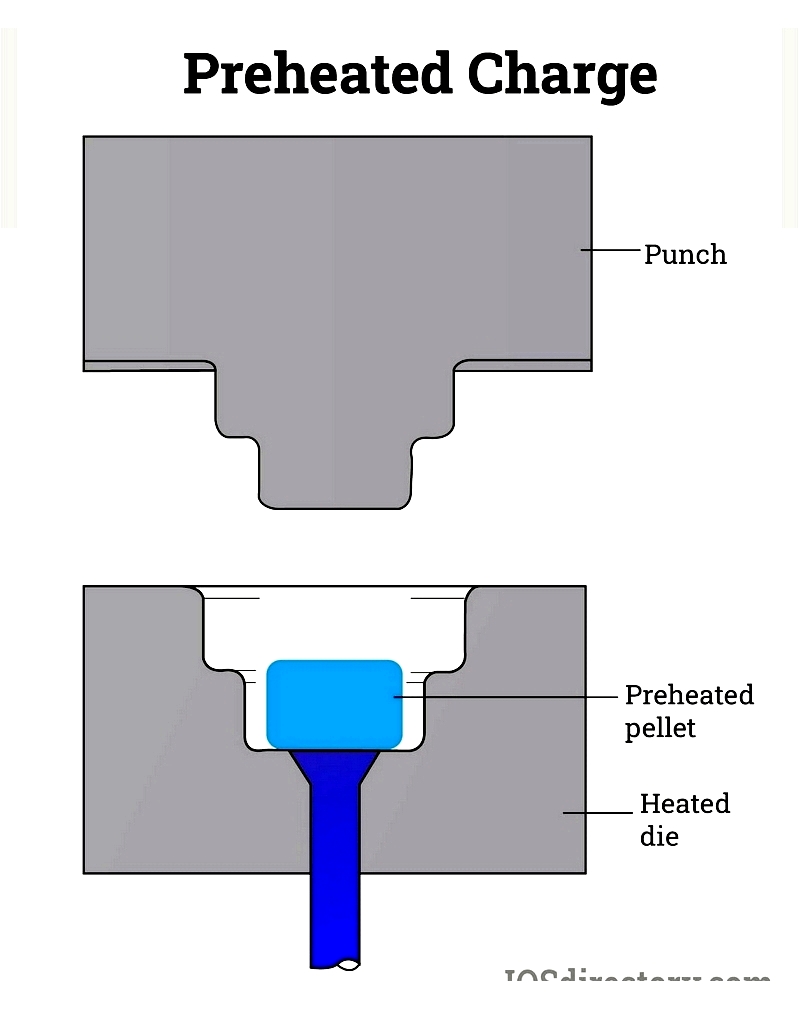

The first step involves mold preparation, which typically includes:

- Thorough mold cleaning

- Application of release agents

- Heating - crucial for improving charge viscosity during loading

Charge Preparation

Compression molding accommodates various materials, resulting in different shapes, sizes, and compositions.

This stage transforms raw materials into forms suitable for compression molding, potentially involving:

- Unpacking

- Cleaning

- Cutting

- Sizing and weighing

- Preheating

Charge preparation often requires significant manual labor due to limited automation.

Charge Loading

This phase positions the charge in the mold's lower section to optimize compression results. The charge distribution considers mold shape, desired thickness, and other factors.

Compression

The mold halves compress the charge to achieve:

- Complete mold cavity filling

- Target product density

- Proper curing conditions

Key compression parameters include:

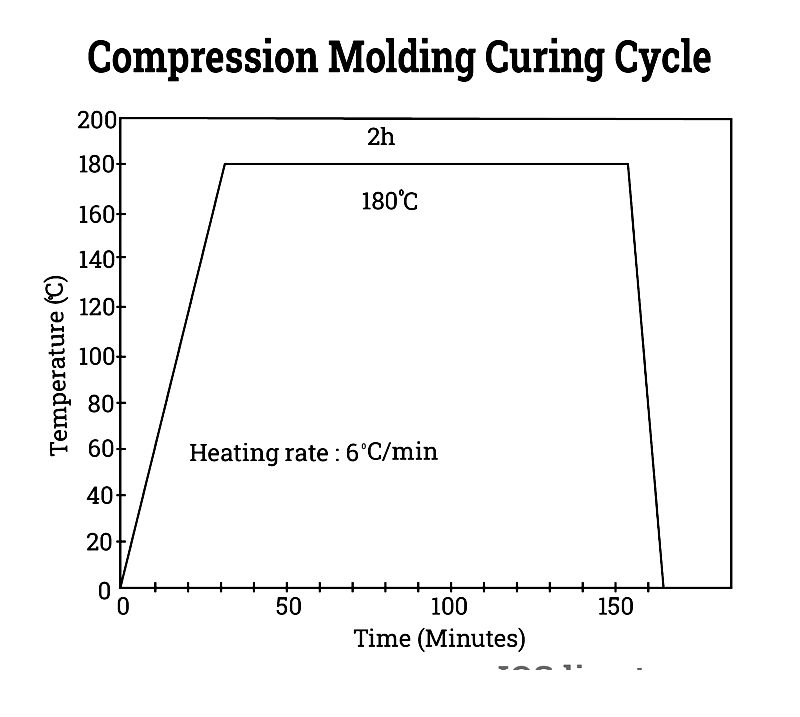

- Temperature - Affects viscosity, with lower viscosity improving material flow. Heating methods vary based on material requirements.

- Pressure - Ranges from 2-14 MPa for carbon fiber reinforced polymers, depending on fiber density.

- Time - Compression duration varies, with some processes requiring extended pressure application.

Curing

This critical stage solidifies the compressed material using:

- Condensation Type: Uses tin catalysts

- Addition Type: Relies on platinum catalysts

Common curing agents include Dimethyl stannane, Tetraethoxysilane, and organopolysiloxane for silicones.

Cooling

Cooling serves important functions:

- Preparing molds for subsequent operations

- Developing optimal product properties

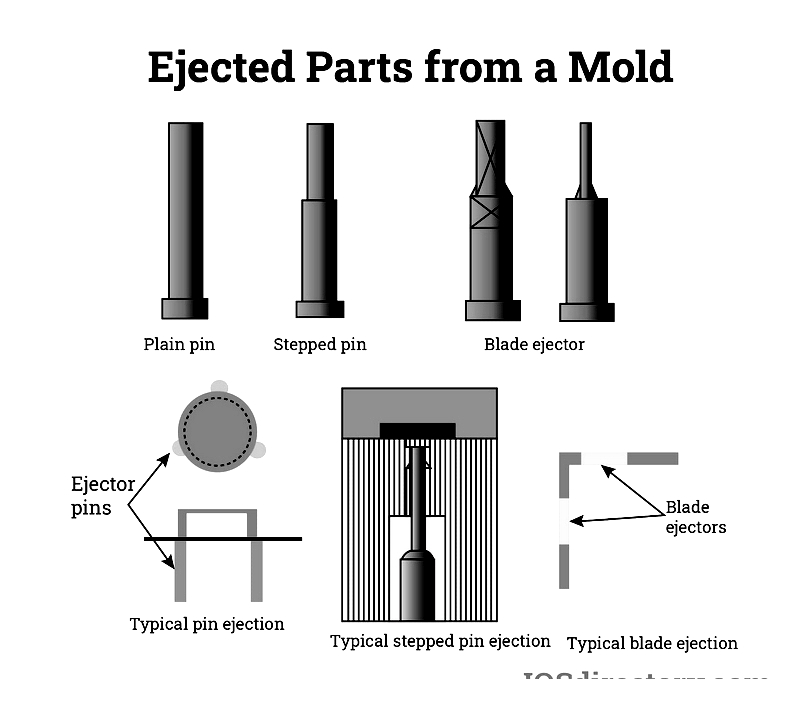

Ejection

Products are removed from molds either manually or automatically. Release agents like PVA, PTFE, or polysiloxanes facilitate this process.

Complex geometries may complicate ejection and automation.

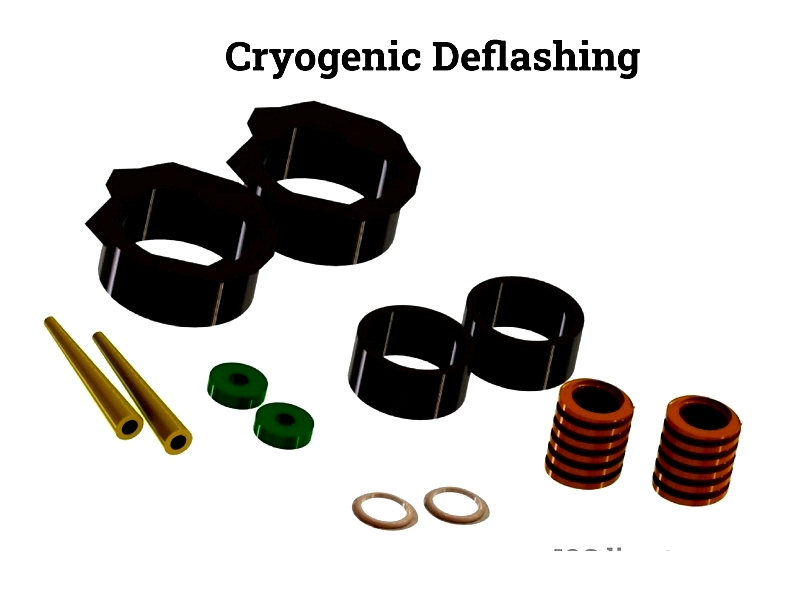

De-Flashing

Removes excess material (flash) from mold parting lines using manual or automated methods like water jets or cryogenic techniques.

Types of Compression Molds

Compression molding is a fundamental process for manufacturing rubber and plastic components, offering precision, durability, and cost efficiency. Understanding mold types is essential for selecting the right technique across industries like automotive, aerospace, and consumer goods.

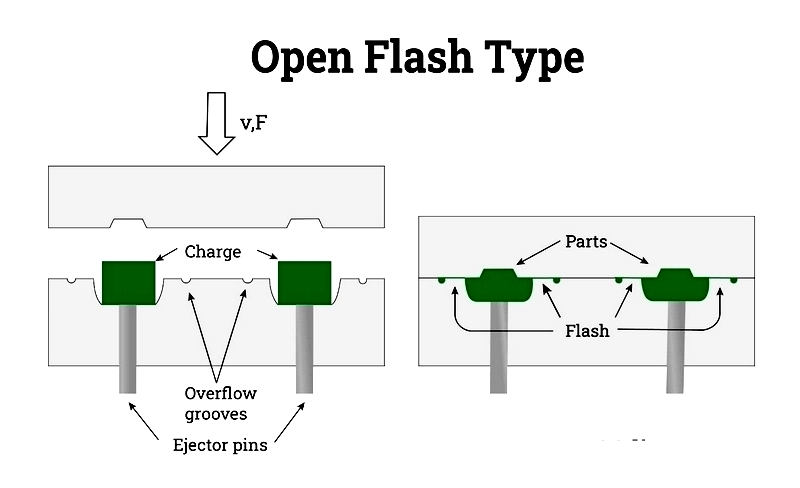

Open Flash Type

Features intentional material overflow to create flash, reducing defects. Ideal for rubber products requiring consistent surfaces.

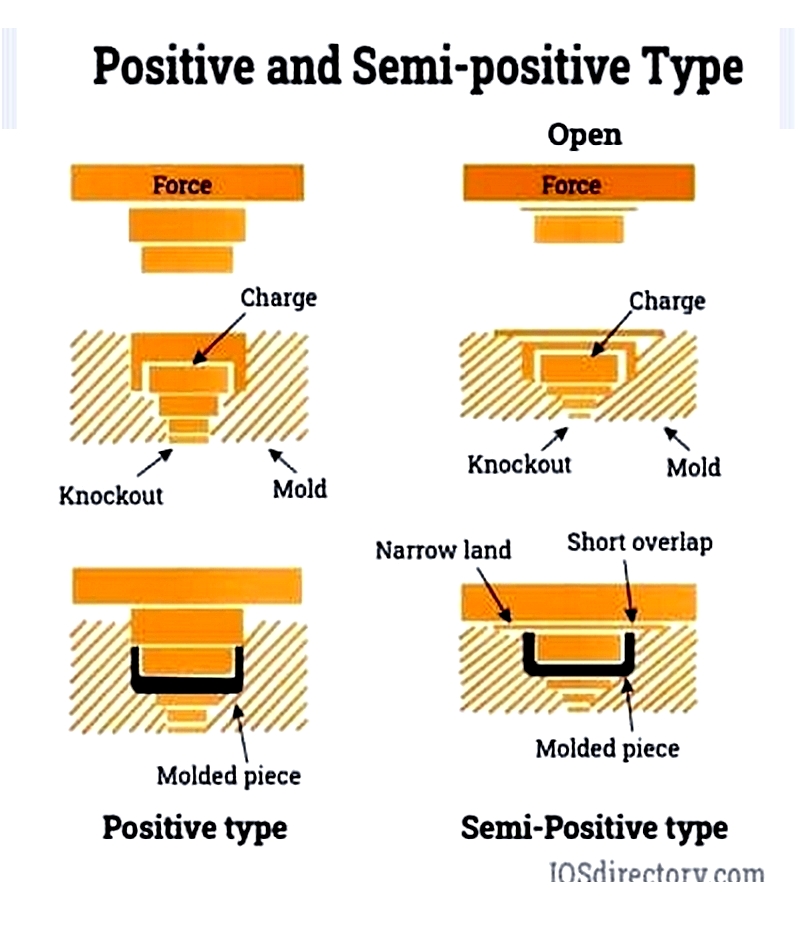

Positive Type

Characteristics include:

- Precise density and strength control

- Minimal material waste

- Potential for trapped air

Semi-Positive Type

Balances flash management with dimensional control, suitable for medium-volume production of complex shapes.

Technology & Innovation in Compression Molding

Recent advancements focus on automation, digital control, and sustainable materials like reinforced thermosets and LSR.

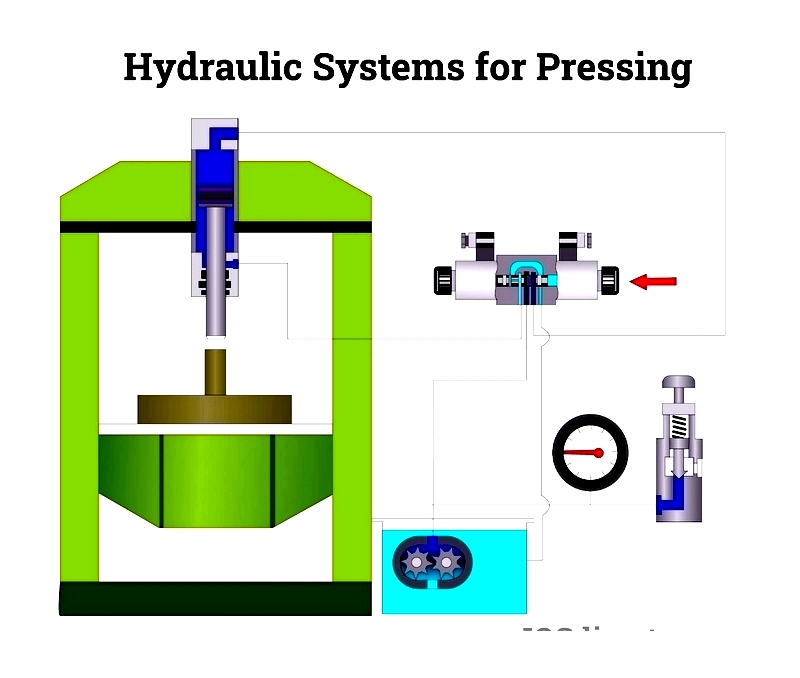

Press Systems

Hydraulic presses dominate industrial applications, offering programmable controls for consistent quality.

Mold Fabrication

Precision-engineered from durable steels using CNC machining for optimal performance.

Production Scaling

Ranges from laboratory prototyping to fully automated mass production.

Advanced Molding Techniques

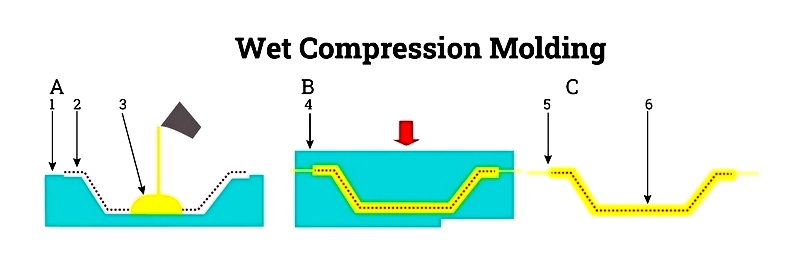

Includes wet compression, vacuum compression, transfer molding, and injection compression methods for specialized applications.