Introduction

This comprehensive guide explores the operating principles, configurations, and construction of three-phase transformers.

- Understanding Electrical Transformers and Their Working Mechanism

- Operating Principle of Three-phase Transformers

- Configuration Options for Three-phase Transformers

- Construction Methods for Three-phase Transformers

- Key Components of Three-phase Transformers

- Additional important Information

Three Phase Transformers (from Johnson Electric Coil Co.)

Three Phase Transformers (from Johnson Electric Coil Co.)Chapter 1: Electrical Transformers - Principles and Operation

An electrical transformer is a passive device that transfers electrical energy between circuits through magnetic flux, generating electromotive force. It can increase (step-up) or decrease (step-down) voltage levels while maintaining current frequency. Transformers also provide electrical isolation between circuits, making them valuable for signal processing applications.

Faraday's Law of Induction

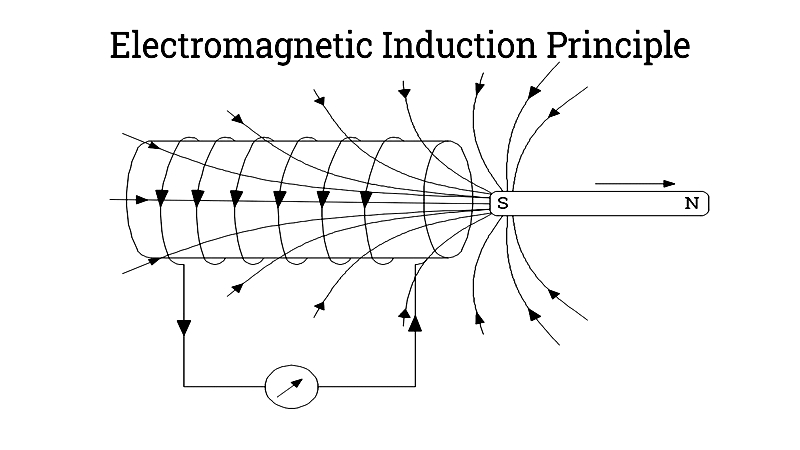

Transformers operate based on Faraday's law of induction, which relates changing magnetic flux to induced electric fields. When a conductor encounters a varying magnetic field - such as from an AC-powered electromagnet - it generates an electric current. This occurs in the transformer's primary winding. As the AC current fluctuates, it creates a corresponding magnetic field that induces current in the secondary winding, maintaining the same frequency as the primary circuit.

Current can also be generated when conductors move through magnetic field lines, a principle commonly applied in electrical generators.

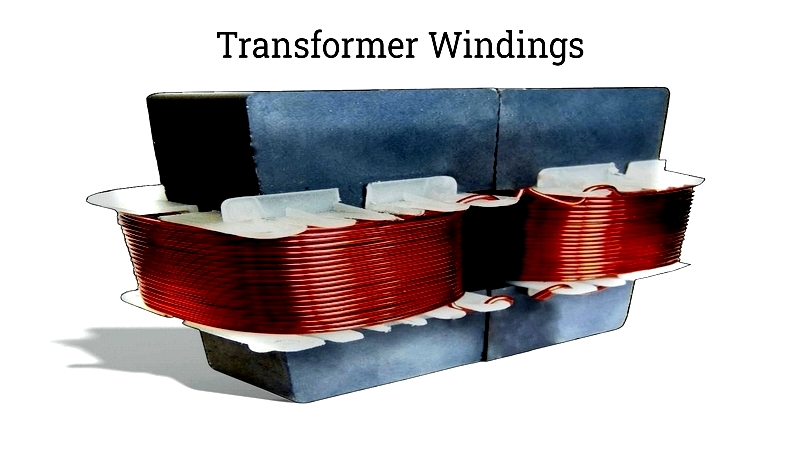

Transformer Construction

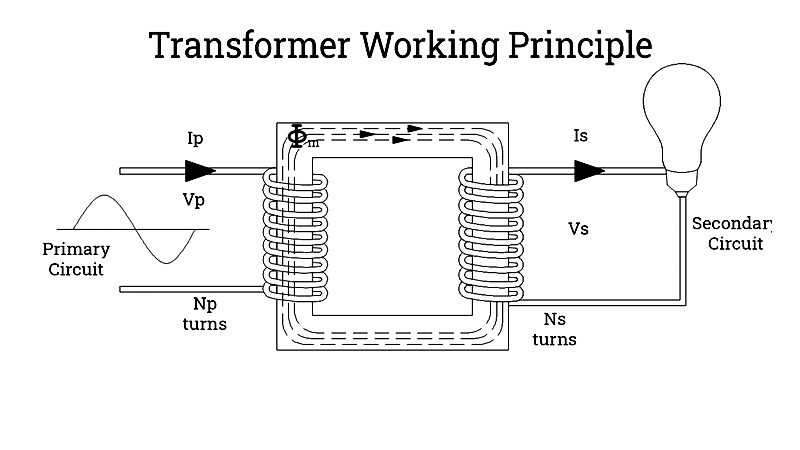

To understand three-phase transformers, we first examine single-phase transformer construction. A single-phase transformer contains two coils: a primary winding connected to the power source and a secondary winding where electricity is induced.

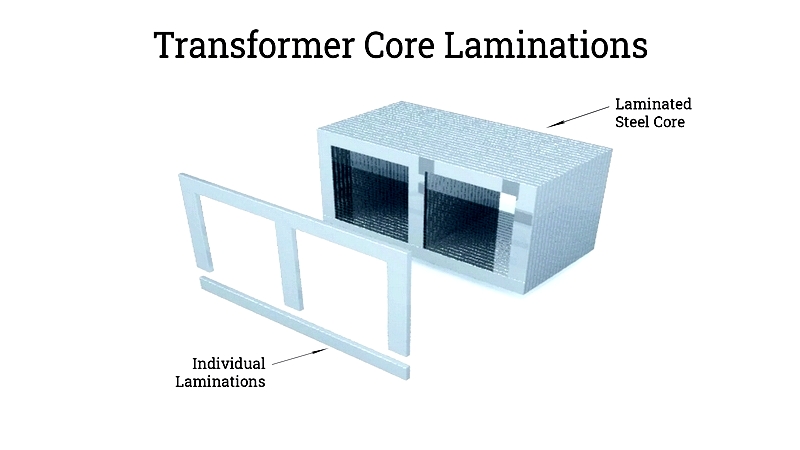

The coils are magnetically linked through an iron core, which channels the magnetic field. This core, acting as a conductor, produces eddy currents that cause energy loss and heat. To minimize these effects, cores use laminated sheets to increase resistivity.

The windings are magnetically coupled but electrically isolated. Voltage adjustment occurs by varying the turns ratio between windings. As linear devices, transformers' output voltage depends on this turns ratio, with voltage changes directly proportional to winding ratio changes.

Transformer Power and Efficiency

Electrical power equals voltage multiplied by current. In ideal transformers, input and output power remain equal - increased voltage results in decreased current and vice versa.

Transformer efficiency typically ranges from 88% to 99%. Power losses include core losses (hysteresis and eddy currents), copper losses, stray losses, and dielectric losses. Hysteresis losses occur from magnetic field reversal energy, while laminations reduce eddy currents.

Copper losses stem from winding resistance, causing voltage drops and heat. Larger conductors minimize these losses but increase transformer size and cost.

Stray losses occur when magnetic fields affect other conductive components, though their impact is less significant than core losses.

Dielectric materials insulate windings, while transformer oil prevents arcing and dissipates heat. Dielectric loss results from insulation and oil degradation over time.

Chapter 2: Three-Phase Transformer Components and Construction

Three-phase transformers are essential in industrial and commercial power systems, enabling efficient power transmission and distribution. Designed for high-demand applications, they differ from single-phase transformers in construction, wiring, and applications while maintaining the same electromagnetic induction principle. Understanding these differences is crucial for power infrastructure, manufacturing, and distribution applications.

Three-Phase System Structure and Advantages

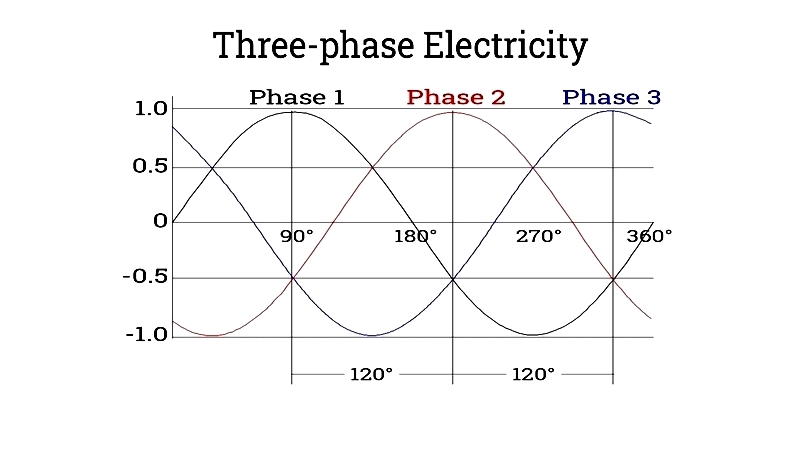

Three-phase AC systems use three conductors with 120° phase offsets, creating three distinct waveforms. This configuration provides continuous power flow with minimal fluctuations, making it ideal for long-distance transmission and heavy machinery.

Winding Configurations

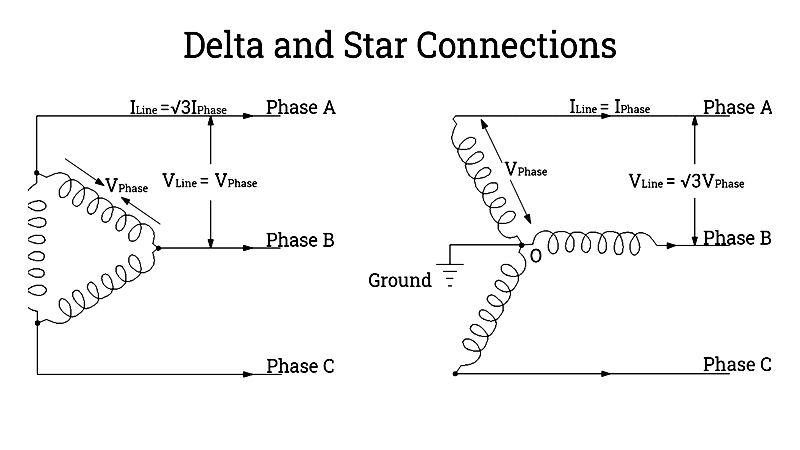

Three-phase transformers contain six windings (three primary, three secondary) arranged around a laminated core. These can be connected in delta (Δ) or star (Y) configurations for different voltage and current requirements.

Delta connections suit lower voltage/higher current applications, while star connections work for higher voltage/lower current needs. These configurations affect voltage transformation, grounding, and fault tolerance. Integrated three-phase designs are typically more efficient than three single-phase units combined.

Key Components

Essential three-phase transformer components include:

- Laminated Iron Core: Guides magnetic flux while minimizing eddy currents

- Copper/Aluminum Windings: Designed for three-phase current handling

- Insulation Systems: Ensures safe high-voltage operation

- Cooling Systems: Includes dry-type or oil-immersed options

- Control Systems: Tap changers and protective relays for voltage regulation and safety

- Protective Enclosures: Weather-resistant housing for various environments

When selecting transformers, consider voltage ratio, kVA rating, insulation class, temperature rating, and efficiency. Professional consultation ensures optimal solutions for specific power distribution needs.