Introduction

This article provides an in-depth examination of electric hoists.

Continue reading to explore topics including:

- Electric hoist overview

- Operating principles of electric hoists

- Selection and operation considerations for electric hoists

- Applications of electric hoists

- And more...

Chapter 1: Overview of Electric Hoists

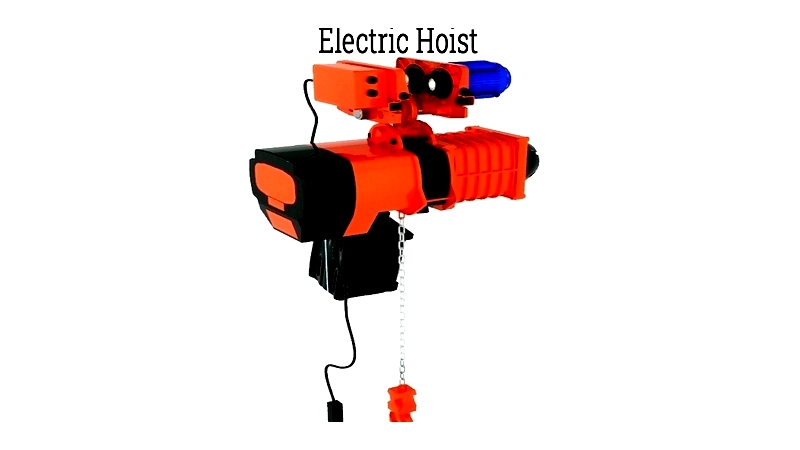

Electric hoists are specifically designed for efficient lifting, lowering, and transporting of materials and products. Powered by electric motors and equipped with control systems for managing lifting operations, they excel at handling heavy loads. These hoists prove particularly useful when conveyors or cranes are impractical. Other hoist types include pneumatic, hydraulic, and manual hoists, each distinguished by their power source.

Typically installed overhead for optimal lifting, electric hoists require power sources and perform best indoors. Common applications include warehouses, automotive repair shops, machining facilities, and manufacturing plants. Some models are built for harsh, high-temperature environments, while others are designed for cleanrooms handling sensitive materials like food and pharmaceuticals. Strict safety protocols must always be followed when operating electric hoists.

By automating lifting and positioning tasks, electric hoists significantly boost productivity, reduce manual labor, and improve workplace ergonomics. They generally operate faster than other hoist types and offer a more cost-effective, space-saving alternative to conveyor systems.

Chapter 2: Hoist Operating Principles

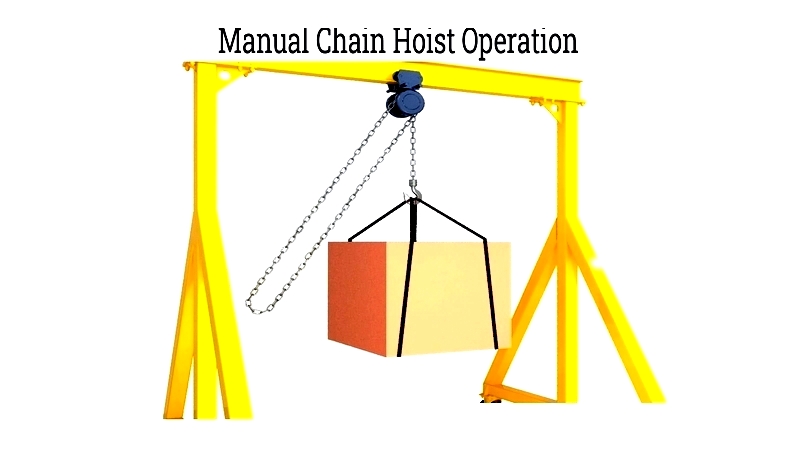

Manual Chain Hoist

Manual chain hoists are fundamental lifting devices widely used in industrial and commercial settings. They convert low input force over long distances into high lifting force over short distances, enabling safe lifting, suspending, and lowering of heavy loads. This mechanical advantage, combined with durable chains and precision gears, makes them cost-effective for material handling in maintenance, construction, and warehousing. While slower than powered alternatives, they allow precise load positioning.

Installed above the load on stable frames or beams, manual chain hoists use two chains: a hand chain for operation and a heat-treated steel load chain for strength. The operator pulls the hand chain to rotate gears, gradually concentrating force to lift heavy objects. A ratchet mechanism acts as a safety brake, locking the load in position and preventing accidental descent when properly engaged.

Manual chain hoists are ideal for lighter-duty or intermittent lifting where portability and minimal maintenance are priorities. For demanding operations requiring speed and power, electric hoists (chain or wire rope types) offer greater productivity and can integrate with overhead crane systems for diverse industrial applications.

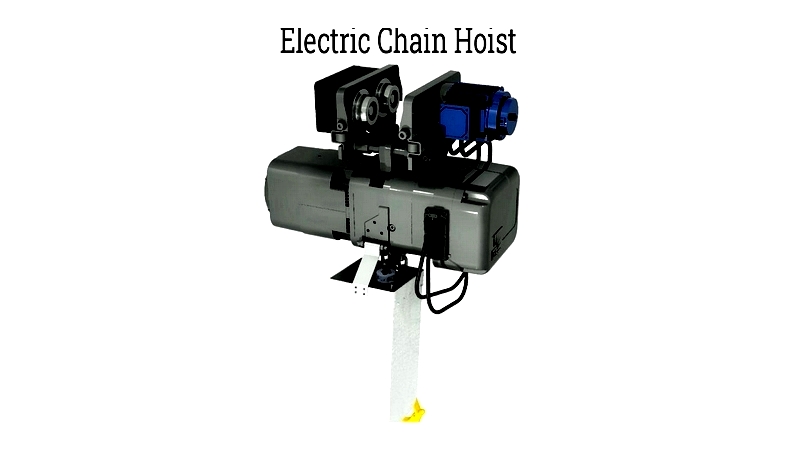

Electric Chain Hoist

Electric chain hoists enhance productivity and reduce strain through powered lifting operations. Using heavy-duty load chains, they can lift weights from hundreds of pounds to several tons. The industrial-grade electric motor converts electricity into mechanical force, housed in a durable aluminum shell with cooling fans for continuous operation.

Mounted via beam clamps or ceiling mounts, these hoists feature hooks for secure load attachment. Push-button controls activate the motor and brake system for precise positioning. The gearbox transmits torque to the chain wheel, raising the load while excess chain collects in a reinforced bag. Limit switches prevent overloads, with additional safety features like thermal protection and emergency stops available.

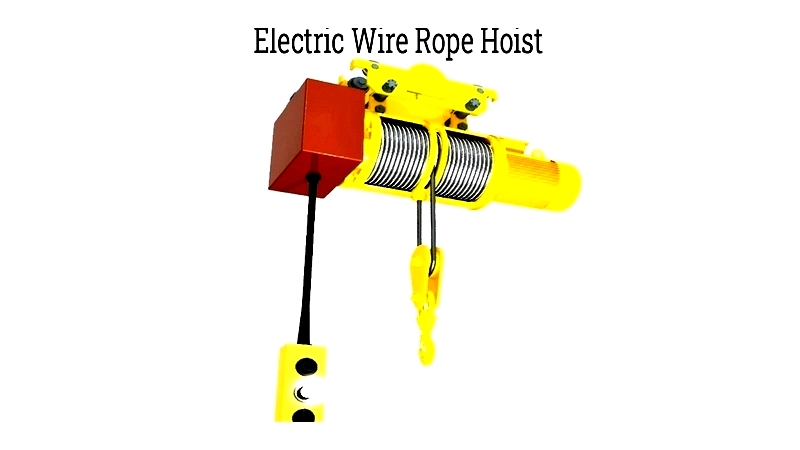

Electric Wire Rope Hoist

Electric wire rope hoists handle heavy-duty lifting with high-strength wire ropes composed of steel strands around a core. Suitable for demanding industries like steel manufacturing and shipbuilding, they offer flexibility and abrasion resistance. The motor and braking system provide reliable control, with torque amplified through a gearbox to a winding drum that evenly distributes the rope.

Modern versions feature intelligent controls, limit switches, and load sensors for safe operation. While more expensive than chain hoists, their higher capacity and speed make them ideal for continuous industrial lifting over greater heights.

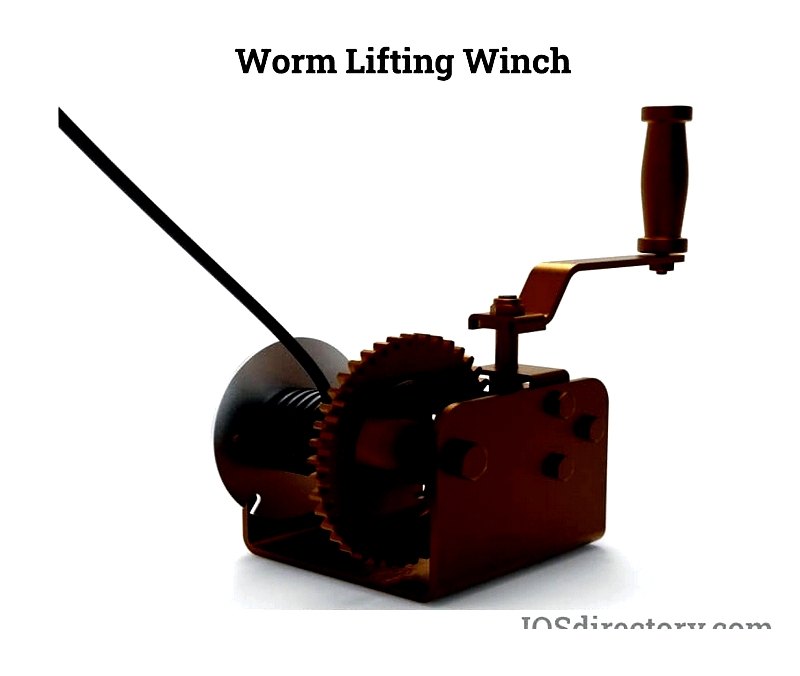

Winches

Winches specialize in horizontal pulling, unlike hoists designed for vertical lifting. Both use cables wound around drums, but winches employ gear braking for static loads while hoists incorporate comprehensive safety systems for lifting.

Common in vehicle recovery and marine applications, winches can be manual or powered. While adaptable for limited vertical use with pulleys, they shouldn't replace hoists for regular lifting. Industrial winches feature various drum configurations and safety systems for demanding environments.