Introduction

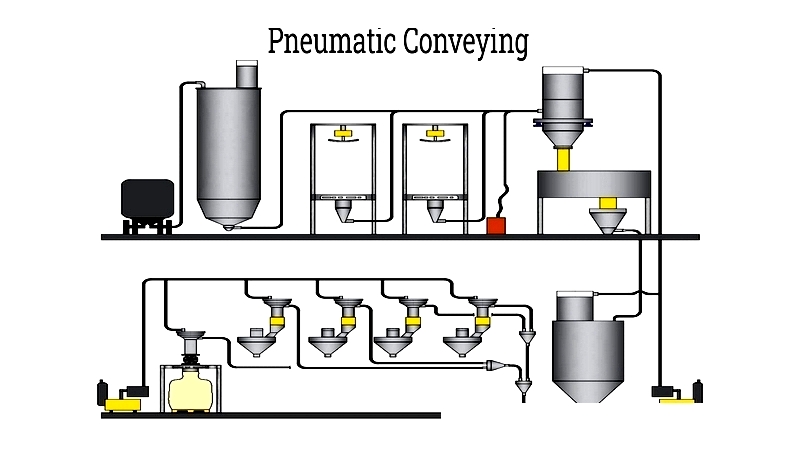

This article provides an in-depth examination of pneumatic conveying.

You'll explore key topics including:

- What is Pneumatic Conveying?

- The Three Types of Pneumatic Conveying Systems

- How to Select a Pneumatic Conveying System

- Pneumatic Conveying Design Principles

- And Much More...

Chapter One – What is Pneumatic Conveying?

Pneumatic conveying is a bulk material transportation method that uses compressed air or gas to move powders and granules through sealed pipelines. This system operates by creating pressure differentials and airflow using fans or blowers, efficiently transporting materials with minimal damage or loss through positive or negative pressure within the conveying line.

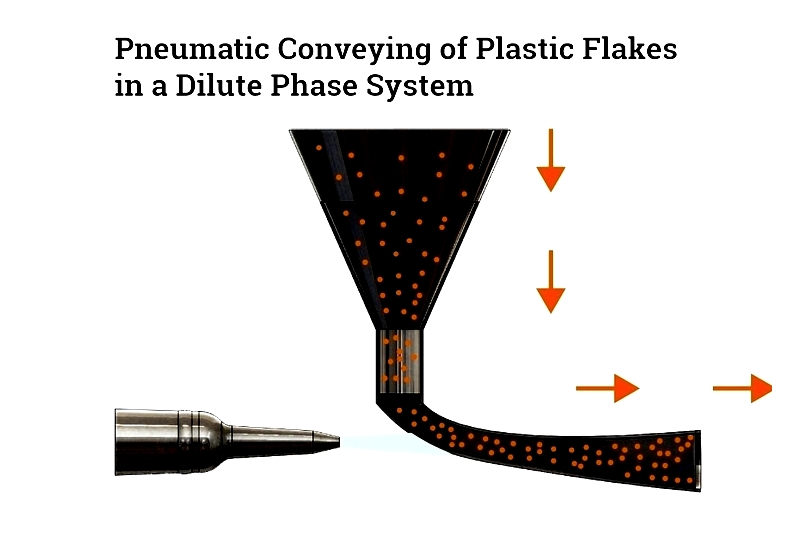

The accompanying image demonstrates pneumatic conveying in action, showing plastic flakes being transported in a dilute phase system with an eductor valve.

All systems require energy to function. While most machinery uses electricity, pneumatic systems utilize compressed air. This setup draws air from storage units, harnessing the pressure created when air enters an enclosed space.

The fundamental principle involves using air to transport bulk materials like grains, cement, powders, and chips through pipelines. The sealed, pressurized air serves as both energy source and transport medium, generating the necessary propulsion force.

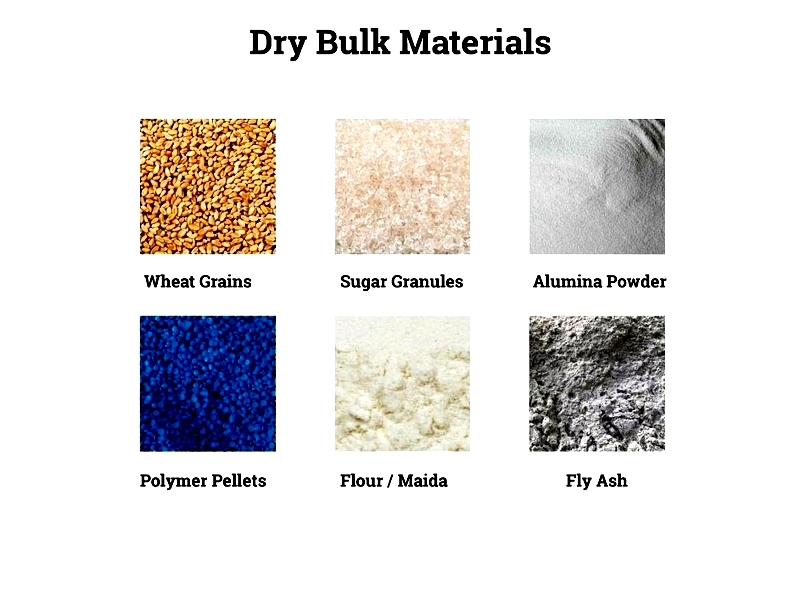

Pneumatic conveying systems handle diverse materials including cement, fly ash, starch, sugar, salt, sand, plastic pellets, oats, polymers, lime, soda ash, plastic resin, dry milk, and animal feeds. They offer energy-efficient solutions for material transfer from railcars, trucks, or silos, and are used in intermodal operations, in-plant transfers, and dust containment.

These systems feature precisely engineered components that work together to transport materials safely, cost-effectively, and efficiently.

Chapter Two – Types of Pneumatic Conveying Systems

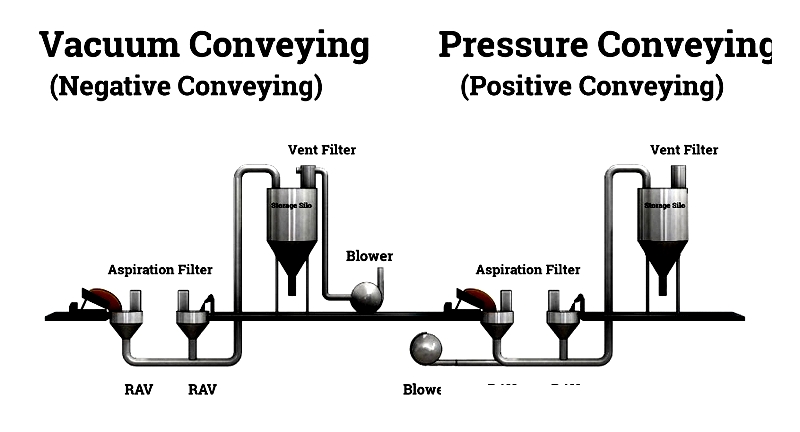

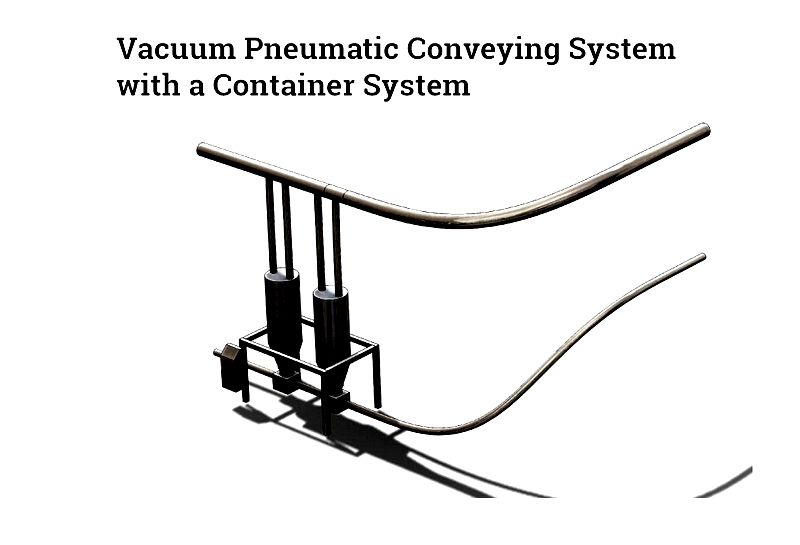

Pneumatic conveying systems are advanced technologies that transport bulk materials through pipelines using air pressure or vacuum. The two primary forms are pressure and vacuum conveying systems. Pressure systems move materials by generating high air pressure, ideal for transferring large volumes of dry bulk solids over long distances in manufacturing and processing applications. Key components include feed lines, rotary gate valves, and pressure containers.

Vacuum systems use negative pressure to draw materials through pipelines to receiving separators. This method offers flexibility and is widely used in automated manufacturing environments where multiple processing units require various powders from centralized sources. Industries like pharmaceuticals and food processing rely on vacuum conveying for dust-free transport of delicate materials.

Some vacuum systems employ venturi valves that create vacuum effects without moving parts, reducing maintenance costs and contamination risks for lightweight powders.

Pneumatic Conveying Classifications

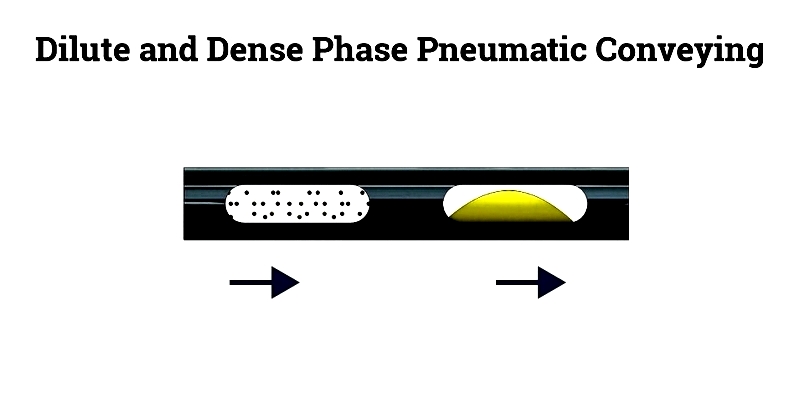

Systems are categorized as dilute phase or dense phase, differing in operating pressure, material velocity, and suitability for various bulk solids. Understanding these differences helps select optimal solutions based on material properties, throughput, distance, and application needs.

Dilute Phase

Dilute phase conveying is common for non-abrasive, free-flowing materials like flour and plastic pellets. It suspends particles in high-velocity air streams using positive pressure (blowing) or negative pressure (vacuum). Positive pressure systems use blowers to force air through lines, with speeds typically ranging 15-35 m/s. Components include pressure vessels, rotary feeders, and dust collectors.

Vacuum dilute phase systems are preferred for batch operations and contamination-sensitive products in industries like pharmaceuticals.

The diagram below contrasts vacuum and pressure systems. Vacuum systems position the blower downstream, while pressure systems place it upstream to push materials toward storage.

Dense Phase

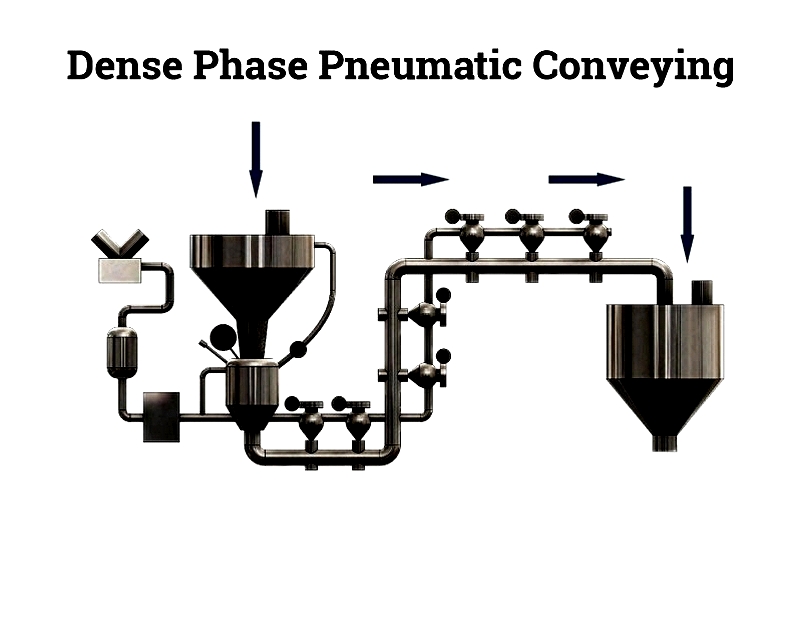

Dense phase systems use high-pressure, low-velocity airflow to move materials in slugs, minimizing product degradation and pipe abrasion. This method suits fragile or abrasive materials like food ingredients and minerals, operating with high product-to-air ratios for gentle handling.

Common in food processing, dense phase conveying prevents degradation of delicate products like meat chunks and vegetables. Its low velocity also reduces pipe wear for abrasive materials.

Booster pulsers ensure uniform material movement in dense phase systems, installed along pipelines to regulate airflow and maintain consistent product flow.

The tightly packed pipeline configuration prevents air bypass, enhancing efficiency while reducing particle contact with pipe walls.

System Selection Guidelines

When choosing between system types, consider material characteristics, conveying distance, capacity requirements, energy consumption, and sanitary needs. Partnering with experienced manufacturers helps determine optimal solutions based on process requirements and total cost of ownership.

Leading industries using these systems include food processing, pharmaceuticals, and chemicals. Proper system selection optimizes operations, extends equipment lifespan, and reduces costs.

Chapter Three – Selecting a Pneumatic Conveying System

Pneumatic conveying provides safe, reliable transport for bulk materials across industries. When selecting systems, evaluate both technical specifications and operational requirements to ensure alignment with material characteristics and production goals.

Material Characteristics

Key material properties affecting system design include:

- Bulk density (affects equipment sizing and airflow requirements)

- Particle size and shape (influences conveyability and wear)

- Friability (important for fragile products)

- Moisture content (may require specialized components)

- Abrasiveness (determines pipeline materials)

- Toxicity (impacts safety measures)

- Combustibility (requires certified components)

System Configuration

Consider plant layout and requirements:

- Pickup and discharge points

- Receiver sizes

- Throughput rates

- Operation mode (continuous/batch)

Vacuum vs Pressure

Vacuum systems suit pressure-sensitive powders where containment is critical. Pressure systems handle heavier, abrasive materials over longer distances.

Dilute vs Dense Phase

Dilute phase offers fast transport for robust materials. Dense phase provides gentle handling for fragile products with minimal breakage.

Cost Considerations

evaluate both capital and operating costs including energy consumption, maintenance, and compliance requirements.