Introduction

This is the most comprehensive guide to CNC machining available online.

You'll discover:

- What CNC Machining is

- Applications of CNC Machining

- Parts and Components Produced by CNC Machining

- Industrial Applications of CNC Machining

- And much more...

Scroll down to begin with chapter one.

Chapter One: What is CNC Machining?

CNC machining is an advanced electromechanical process that precisely controls tool movement across three to five axes, expertly removing material to create accurate parts. Designs originate in CAD software and are converted into CNC codes that provide specific instructions to the machinery.

This process ensures high-quality turned components for diverse applications, using both vertical and horizontal machining approaches.

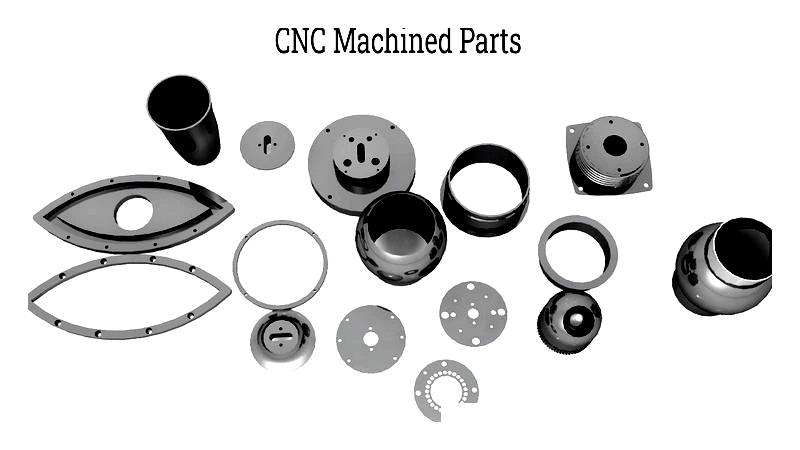

CNC machines can complete parts in a single operation with remarkable efficiency. They produce various components including bushings, fasteners, fittings, machined parts, shafts, and more.

Chapter Two: The CNC Machining Process

CNC (Computer Numerical Control) machining is a precise manufacturing process that creates custom parts from metals, plastics, and composites. Using computer-controlled tools like mills and lathes, it automates operations based on digital designs. The process starts with CAD models that convert into detailed machine instructions.

After converting designs into machine code (G-Code or M-Code), CNC equipment executes programmed steps with high accuracy. This digital workflow ensures repeatability, making CNC ideal for prototyping and production in aerospace, automotive, and medical industries.

The CNC Machining Process

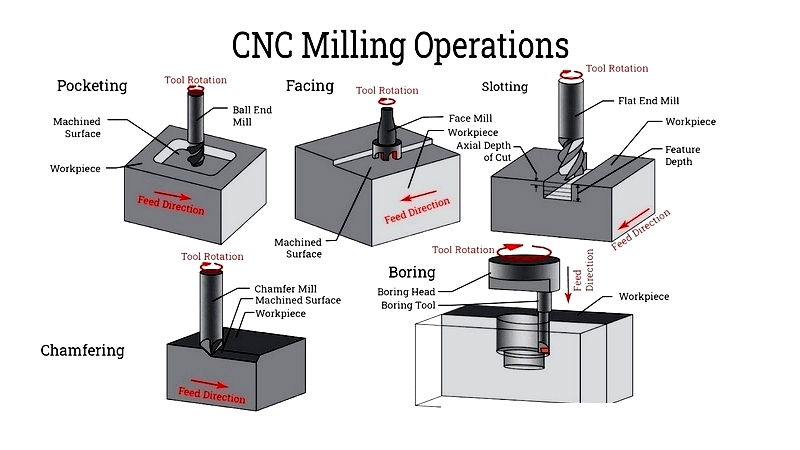

Unlike additive methods, CNC machining is subtractive, removing material from a workpiece to achieve precise geometries. Starting with solid material, it shapes components using computer-guided tools through milling, turning, and drilling operations.

CNC machining supports rapid prototyping, mass production, and custom parts with varying complexity.

Computer Programming

CNC manufacturing depends on precise programming. Using G-Code and M-Code, engineers program tool movements, speeds, and cuts for optimal efficiency. Quality programming minimizes errors during production.

Computer Aided Design (CAD) and Computer Aided Manufacturing (CAM)

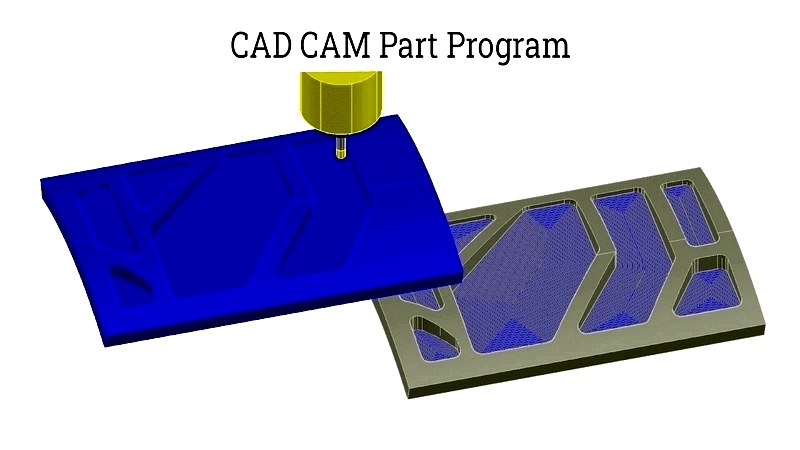

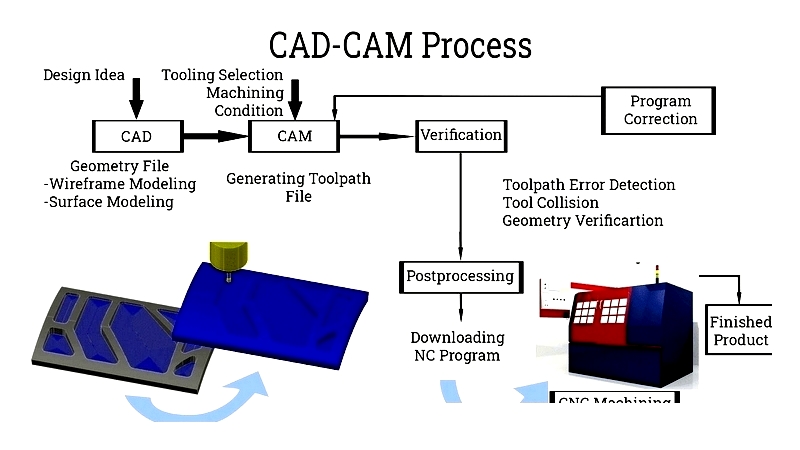

CAD-CAM integration drives modern CNC workflows. CAD software creates detailed 2D/3D models, while CAM generates toolpaths and converts designs into machine code. Together, they enable precise operations like milling and drilling with minimal manual input.

CNC Machine Setup

Setup involves selecting appropriate cutting tools for the operation. Tools can be changed manually or via Automatic Tool Changers (ATCs) for efficiency. Calibrating tool offsets ensures accurate cuts, while proper coolant systems maintain tool life and part quality.

Work Holding

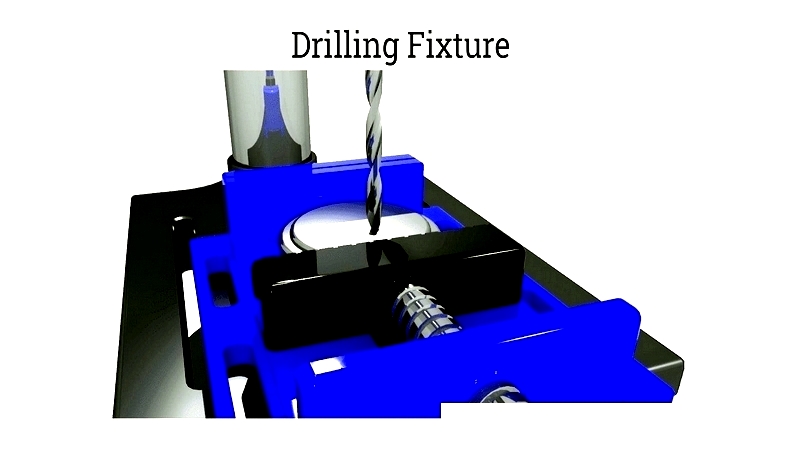

Work holding devices secure workpieces during machining. Custom solutions like vices and chucks ensure stability and accuracy across production runs, protecting both parts and machines.

Loading the G-Codes

G-codes control machine motions and functions. They can be generated by CAM software or written manually, then transferred to machines via various methods for flexible production.

Program Proofing

Before machining, programs are verified through simulations or dry runs. This step prevents errors and ensures efficient production.

Machining the Part

After verification, machining begins with close monitoring of the first piece. Automated inspection maintains quality throughout production.

Execution

CNC machining enables repeatable, high-speed production of precision parts for industries requiring tight tolerances. When selecting CNC solutions, consider material compatibility, volume needs, and secondary operations to optimize production.