Introduction

This article offers a comprehensive overview of strain gauges.

Continue reading to explore topics including:

- What is a Strain Gauge?

- History of Strain Gauges

- Strain Gauge Operating Principles

- Types of Strain Gauges

- And more...

Chapter 1: What is a Strain Gauge?

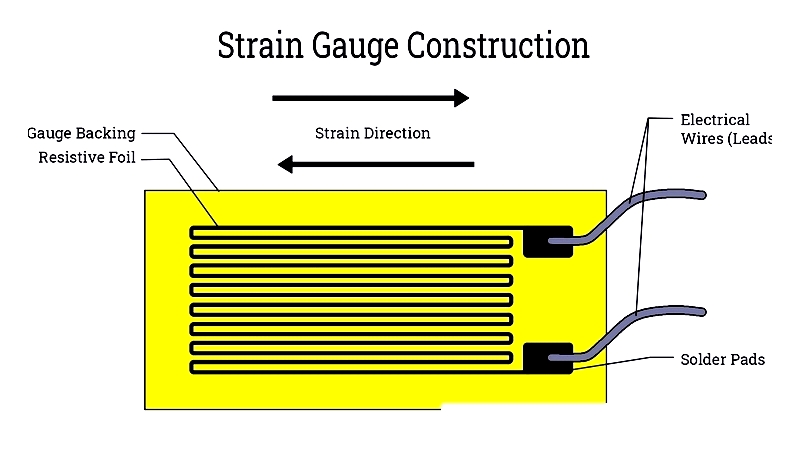

A strain gauge is a sensor that measures resistance changes caused by applied force, converting these changes into measurable data. It consists of a thin metal conductor foil attached to a flexible backing material called the carrier. Electrical wires are soldered to the foil, allowing current to pass through. When the measured surface stretches or compresses, the strain gauge deforms accordingly, resulting in resistance variations that indicate dimensional changes.

To use a strain gauge, it is first mounted on the object to be tested. When force is applied, the gauge measures the resulting deformation—whether elongation, compression, or other changes—which translates into detectable resistance variations.

Strain gauges can detect various types of stress, including tensile, compressive, bending, torsional, and shear stresses. They are highly sensitive, capable of identifying even the slightest changes in an object's shape. Because the resistance changes they detect are extremely small, strain gauges use ultra-thin metallic strips to accurately measure these minute variations.

Strain gauges are primarily used in manufacturing force and pressure transducers like load cells, which convert mechanical loads into electronic signals for easy interpretation. Load cells with strain gauges are the most common type and are widely used for weight measurement.

In weighing applications, strain gauge load cells are attached to a structural component that deforms under weight. Modern load cells often incorporate multiple strain gauges to improve accuracy. Beyond weight measurement, these load cells are used in automation, process control, biomechanics, equipment monitoring, structural evaluation, bulk material weighing, testing, and quality assurance. This technology was pioneered by William Thomson in 1856.

Chapter 2: What is the history of strain gauges?

The invention of strain gauges revolutionized mechanical and structural measurement. Their early development is closely linked to the Wheatstone bridge circuit, a key component in precision measurement. Charles Wheatstone introduced this circuit in 1843, enabling accurate measurement of small resistance changes—a principle central to strain gauge operation. William Thomson (Lord Kelvin) further refined this concept in 1856, establishing the theoretical foundation for strain gauge technology.

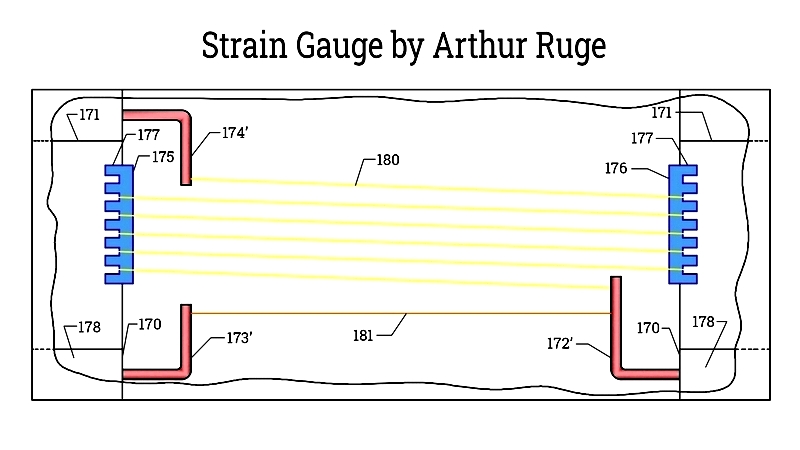

By the early 20th century, practical strain gauges began to emerge. In 1938, Edward E. Simmons, an electrical engineer at the California Institute of Technology, developed one of the first functional resistance strain gauges. His design used thin resistance wires woven with silk threads to measure microstrain and tensile forces. Simmons attached the gauge to a steel cylinder and measured force impulses from a pendulum impact, marking a major advancement in stress analysis and structural testing.

Around the same time, Arthur C. Ruge, a mechanical engineer at MIT, created a similar sensor to measure strain in a seismic model of an earthquake-resistant water tank. Ruge's design used fine wires on a paper strip, forming a simple yet effective strain gauge. This innovation led to the modern bonded resistance-type strain gauge used in load cells, force sensors, and torque sensors today.

Collaboration between academia and industry accelerated strain gauge development. Ruge and his team at MIT commercialized their invention, leading to widespread use in testing, quality assurance, and structural monitoring. Advances in materials and manufacturing techniques, such as photolithography and precision circuit printing, replaced traditional wound-wire designs. Today, strain gauges are used in aerospace, automotive, civil engineering, and industrial automation, often integrated into complex sensor arrays for multi-axis measurements and real-time data acquisition.

Modern strain gauges come in various types, including foil, semiconductor, thin-film, and MEMS-based designs. When selecting a gauge, factors like gauge factor, temperature compensation, resistance value, and compatibility with data acquisition systems are crucial for accuracy. Leading manufacturers offer a wide range of products and services for research, industrial, medical, and OEM applications.