Introduction

This article provides an in-depth exploration of data acquisition systems.

It covers various topics including:

- Principles of Data Acquisition Systems

- Measurements, Modules & Methods in Data Acquisition Systems

- Types of Data Acquisition Systems and Signals

- Applications and Benefits of Data Acquisition Systems

- And More...

Chapter 1: Understanding the Core Principles of Data Acquisition Systems

This chapter examines the fundamental aspects of data acquisition systems, including their key components and the processes for collecting and analyzing data.

Defining a Data Acquisition System

A data acquisition system consists of sensors, measurement tools, and computers working together to collect and analyze data. It provides insights into electrical or physical phenomena by thoroughly interpreting gathered information.

Understanding how these systems function requires knowledge of their data processing and recording mechanisms. For instance, they can measure a heating coil's temperature to ensure precise heating. This evaluation of efficiency through temperature measurement is enabled by data acquisition systems. Similarly, they measure voltage drops across electrical resistors.

The primary goal of recording electrical and physical phenomena is to facilitate detailed analysis. Using specialized software, these systems process and store data in user-friendly formats, capturing real-world information for scientific or engineering evaluation.

Data acquisition systems come in handheld and remote versions. Handheld models are suitable for direct interaction, while remote systems allow measurements from a distance when in-person access isn't possible.

Essential Components of a Data Acquisition System

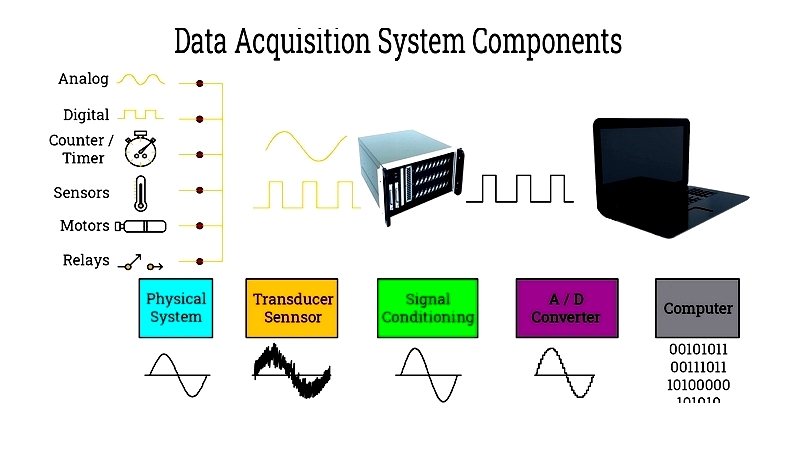

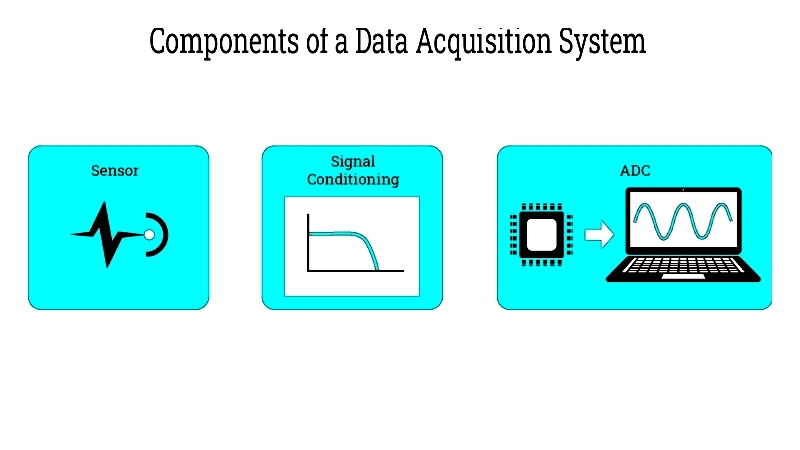

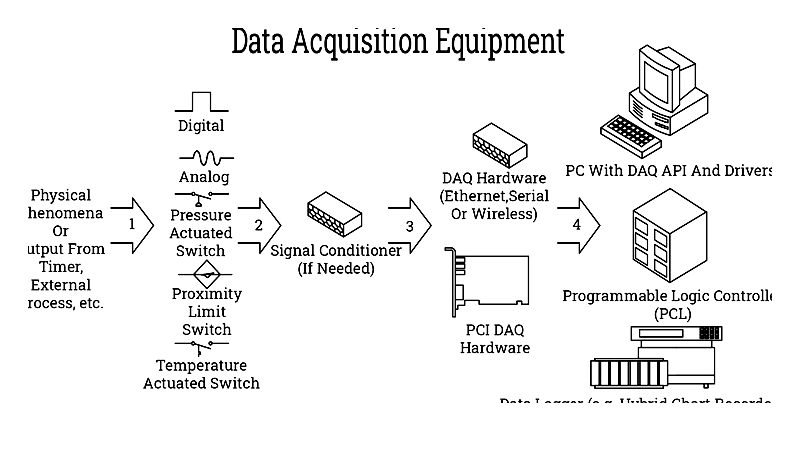

The data collection process begins by identifying physical attributes to measure, such as temperature, light intensity, vibration, or pressure. These properties must first be converted into a format suitable for the system to sample.

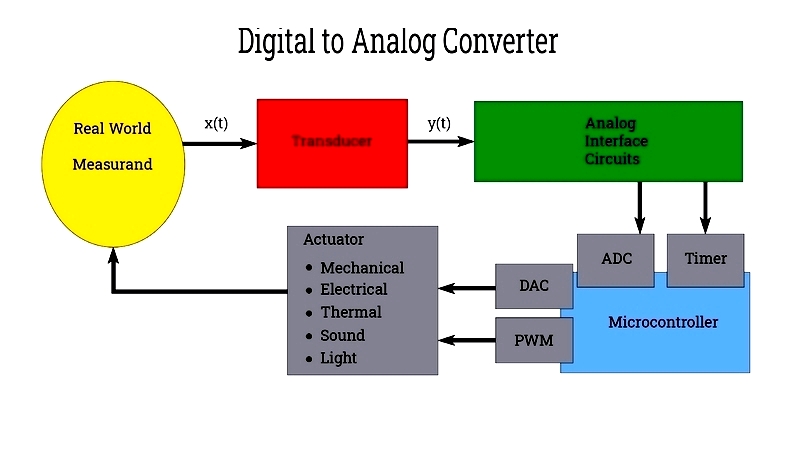

Sensors handle this conversion. A complete data acquisition system includes hardware and software to measure physical properties, featuring DAQ hardware, sensors, actuators, signal conditioning equipment, and computers with DAQ software. For precise timing, especially in event-mode systems, an independent timing mechanism may be necessary.

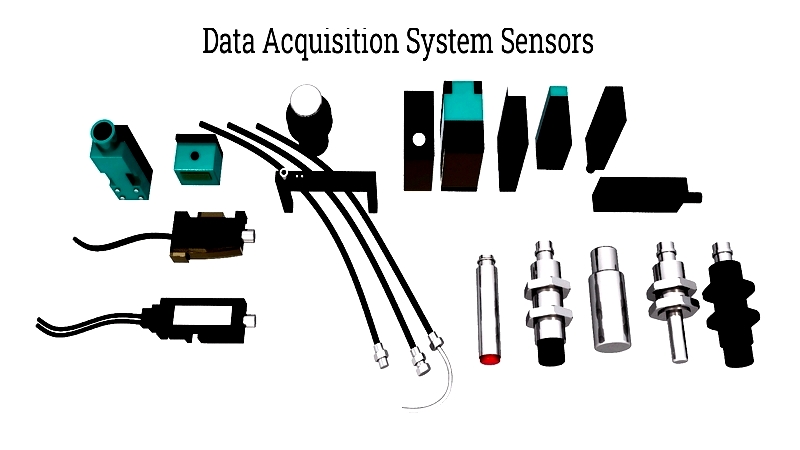

Sensors

Sensors, or transducers, interact with the measured subject directly or indirectly, converting physical values into electrical signals. Different sensors are used depending on the application, such as temperature sensors for heat measurement or photovoltaic sensors for light.

All sensors transform analog signals—like temperature or light—into digital signals for computer processing. High-quality sensors in DAQ systems ensure accurate readings with minimal noise.

Signal Conditioners

Electrical signals from sensors may contain noise or be too weak for accurate measurement. Signal conditioners refine these signals, using filter circuits to remove noise and amplification circuits to strengthen weak signals. They may also perform linearization, calibration, and excitation, depending on sensor characteristics.

Data Acquisition Hardware

This hardware bridges sensors and computers, connecting via USB or PCI-express slots. It converts sensor signals into digital formats for computer interpretation and analysis.

Analog-to-Digital Converters (ADCs)

ADCs transform analog signals into digital data, serving as the core of every DAQ system. Their resolution, defined by bit depth, determines the accuracy of conversion. Higher bit counts provide more discrete levels, similar to finer markings on a measuring device.

For example, a ruler with millimeter markings offers greater resolution than one with centimeter markings. Selecting the appropriate ADC resolution depends on specific measurement needs.

Digital-to-Analog Converters

These components facilitate binary signal input and output, enabling smooth data exchange between the system and external devices.

Single-Ended Input Converters

These converters support single-ended wire connections for signal measurement and interface.

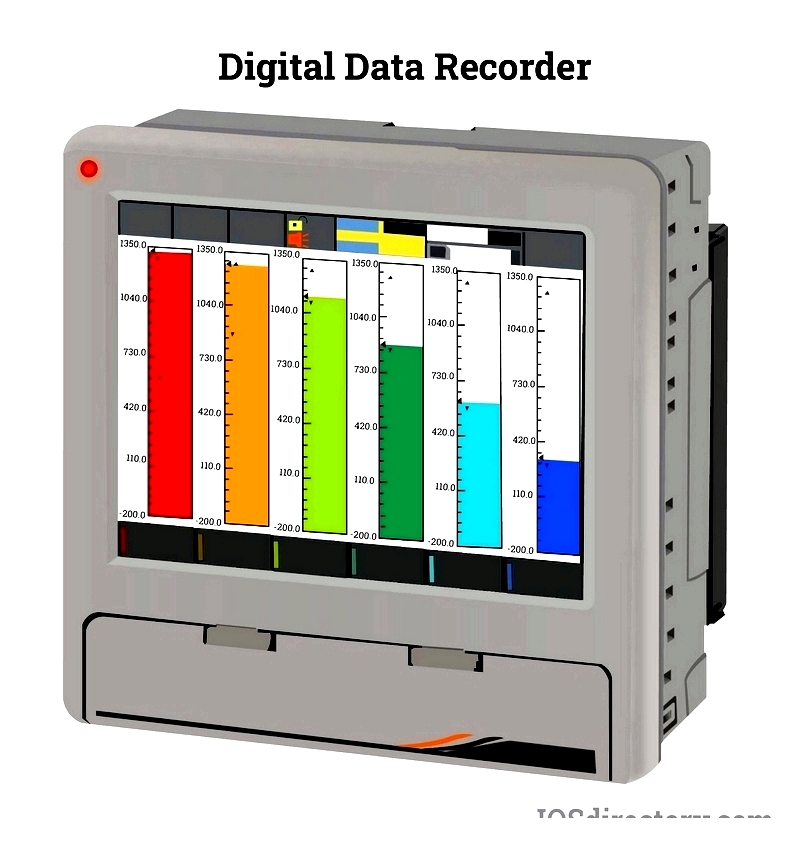

Some DAQ hardware operates independently without a computer, featuring embedded processors for real-time data representation. Examples include oscilloscopes and data loggers.

Data Sampling Rate

The sampling rate, measured in hertz, indicates how many samples are taken from a continuous signal over time. It's crucial for accurate trend interpretation. Low rates may miss or distort trends, while modern computers typically handle high rates without storage concerns.

Understanding sampling rates is essential. Short-term tests may require high rates to capture rapid fluctuations, while longer analyses might use slower intervals.

Computers

Computers play a pivotal role in DAQ systems, processing data from hardware for analysis. Specialized DAQ software translates raw data into meaningful results, enabling advanced analyses.

Chapter 2: Measurements, Modules, and Methods in Data Acquisition Systems

This chapter explores the key measurements, modules, and methods used in modern DAQ systems. It covers how industrial and scientific solutions collect and analyze data using sensors, signal conditioning modules, transducers, and software.

Data Acquisition Systems Measurements

DAQ systems capture and digitize various physical phenomena, typically starting as analog signals. These inputs—like voltage and current—are converted to digital formats via ADCs for computer analysis.

Common measurement parameters include:

- Current (AC/DC)

- Voltage (AC/DC)

- Strain

- Frequency or time interval

- Pressure

- Temperature

- Distance

- Vibration

- Angles

- Digital signals

- Weight

Specialized DAQ devices use various sensor interfaces for signal conditioning, ensuring accurate measurements. Flexible multi-channel modules suit laboratory, industrial, and field applications.

Data Acquisition Cards and Modules

Advanced systems use modular, rack-mounted platforms with function-specific DAQ cards. These include analog input/output cards, digital I/O cards, and counters, adhering to standards like PCI or USB for compatibility and scalability.

Data Acquisition Software

Robust software controls, visualizes, and analyzes measurement data. It configures channels, sets logging intervals, and manages triggers. Options include custom solutions (using LabVIEW or Python) or pre-built packages with features like real-time logging and cloud connectivity.

Data Acquisition Transducer Signals

Transducers convert physical energy into electrical signals. Analog output transducers require high-resolution ADCs, while digital output transducers need high-speed digital inputs. Signal conditioning modules improve accuracy and reduce noise.

Data Acquisition Methods

Various methods are used depending on application needs:

Bit-Stream Disk-to-Image File

Creates a complete forensic image of a storage device for analysis or restoration.

Bit-Stream Disk-to-Disk

Produces an exact, bootable clone of a source device for recovery or duplication.

Logical Acquisition

Focuses on selective data collection, such as email databases or patient records.