Introduction

This article provides an in-depth exploration of electronic enclosures.

Key topics covered include:

- Principles of Electronic Enclosures

- Types of Electronic Enclosures

- Benefits of Using Electronic Enclosures

- And More...

Chapter 1: Understanding Electronic Enclosure Principles

This chapter examines the concept of electronic enclosures and describes their manufacturing process.

Defining Electronic Enclosures

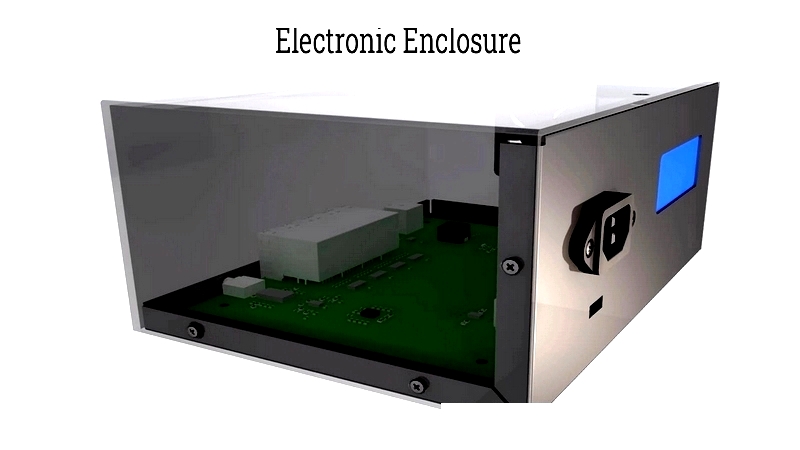

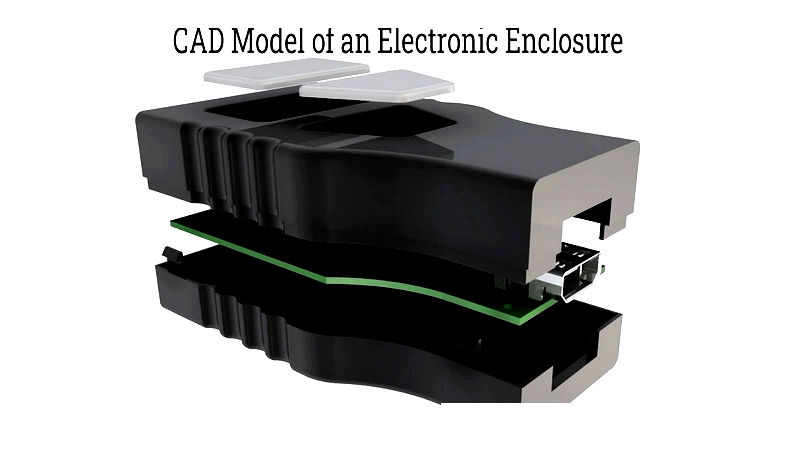

Electronic enclosures are protective housings designed to safeguard components like switches, relays, PCBs, integrated circuits, power sources, and processors. Available in various materials and sizes, these enclosures are tailored to specific applications, environments, and budgets. The diagram below illustrates an electronic enclosure protecting its internal components.

Consider electronic devices exposed to water, accessible to children, or operating in hot, humid conditions. Without protection, such devices could suffer environmental damage and pose safety risks. To address these concerns, engineers developed protective casings called electronic enclosures that shield components from environmental hazards.

The Role of metal Boxes

metal boxes are durable containers for housing and protecting items. Aluminum and stainless steel enclosures fall into this category. Commonly used as fuse boxes and outdoor electrical meter boxes, metal enclosures also protect electrical devices in commercial settings.

In industrial environments, electronic enclosures prevent damage from impacts, debris, and contamination. They reduce risks from workplace accidents involving personnel or machinery, minimizing potential hazards like explosions or electrical failures.

The International Electrotechnical Commission (IEC) provides guidelines for selecting appropriate enclosures based on application. For example, telecommunications metal enclosures must prevent signal interference. Choosing unsuitable enclosures can lead to operational issues.

Manufacturing Electronic Enclosures

Several techniques are used to produce electronic enclosures:

CNC Machining

CNC machining uses subtractive processes where machines follow CAD files to precisely cut materials. This method allows accurate reproduction of designs and is suitable for creating complex geometries.

The same CNC program can produce both plastic and metal enclosures, making it versatile for different materials.

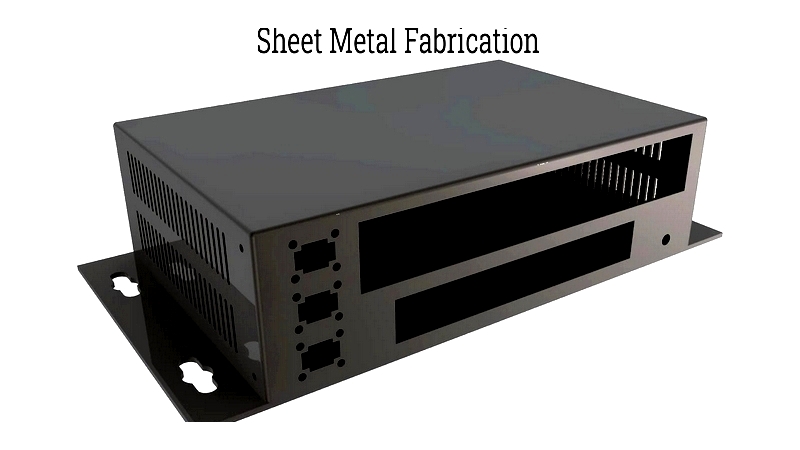

Sheet metal Fabrication

This process forms flat metal sheets into enclosures through folding and assembly. It's cost-effective and efficient compared to CNC machining, with lower per-unit costs at higher volumes.

Commonly used for outdoor and desktop enclosures, this method requires significant initial equipment investment.

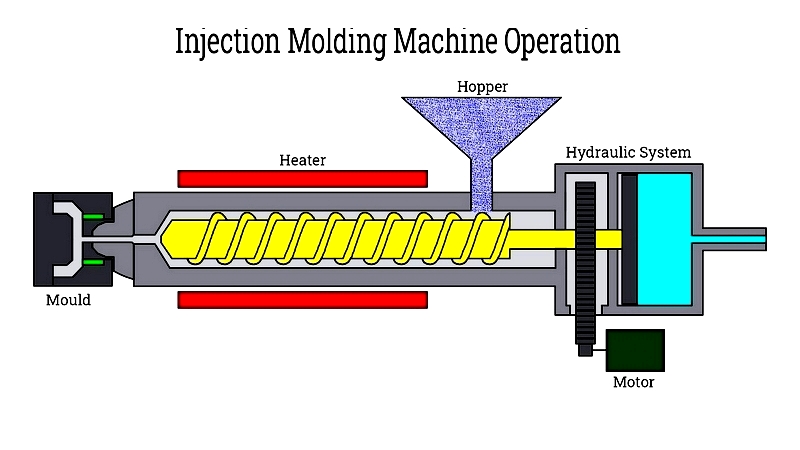

Injection Molding

Injection molding shapes heated materials by forcing them into molds. This method produces simple enclosures for items like remote controls, game controllers, and displays.

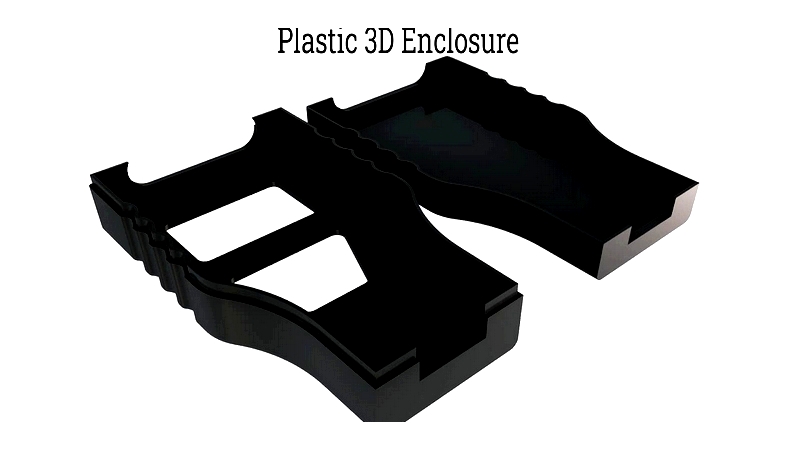

3D Printing

3D printing builds enclosures layer by layer from CAD files. This additive method enables complex designs difficult to achieve with other techniques.

Suitable for prototyping and small batches, 3D printing works with both plastic and metal, though production speeds are slower than traditional methods.

Key Enclosure Design Considerations

important design factors include:

Product Requirements

Product Requirements documents (PRDs) specify essential features and functions. These guide enclosure design by outlining needs like heat management, moisture resistance, and component visibility.

PRDs help determine appropriate materials, costs, and manufacturing methods for each application.

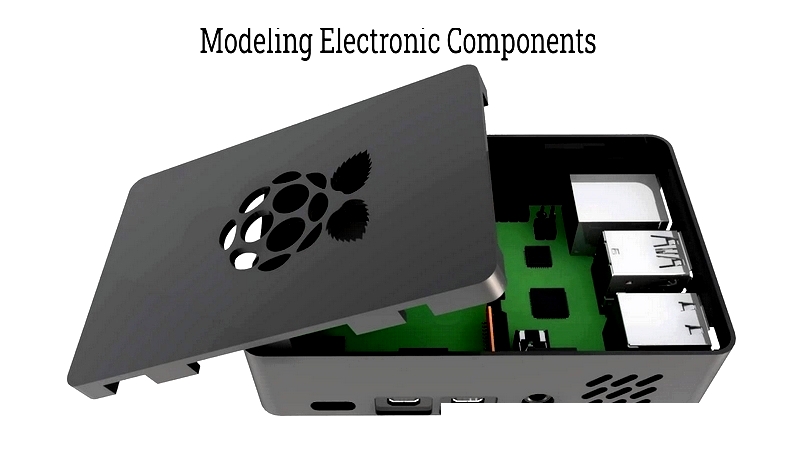

Modeling Internal Components

Effective enclosure design requires understanding component layout. Proper spacing prevents interference, overheating, and short circuits, extending component lifespan.

Expert consultation ensures optimal component arrangement and enclosure design.

Designing the Enclosure Shell

After modeling components, designers create 3D CAD models of the enclosure shell. Wall thickness is critical - too thin compromises durability, while too thick may trap heat.

Verifying CAD Against BOM

Before production, CAD models should be cross-checked with Bills of Materials (BOMs) using specialized software to prevent discrepancies.

Chapter 2: Types of Electronic Enclosures

Electronic enclosures—also called cabinets, casings, or housings—are categorized by material, application, and environment. These protective cases shield components from dust, moisture, EMI, and physical damage in electronics manufacturing, electrical engineering, and industrial automation. Understanding enclosure types helps select solutions meeting user needs, industry standards, and NEMA/IP ratings.

Material-based Classification

Enclosures are primarily metal or plastic, each offering distinct advantages for protection and compliance.

metal Enclosures

Widely used in commercial and industrial settings, metal enclosures protect control panels, junction boxes, and electrical devices. Their strength, durability, and EMI shielding make them ideal for stationary, high-risk applications.

In industrial automation, metal enclosures ensure reliable operation in harsh conditions with dust, debris, and chemicals. Their ingress protection and corrosion resistance enhance safety and longevity.

Available in various sizes and shapes, metal enclosures are manufactured through stamping, punching, and sheet metal fabrication to meet standards.

Aluminum Enclosures

Aluminum enclosures provide EMI shielding and resist impacts, corrosion, and weather. Their lightweight and corrosion-resistant properties suit network communications, power supplies, and test instruments.

Essential in aerospace, telecom, and medical fields, aluminum enclosures often use CNC machining or die casting. They facilitate heat dissipation in high-power electronics.

Aluminum Enclosure Design

Key design parameters include:

- Material: Alloys like 5052, 6061, or 6063 balance strength, conductivity, and cost

- Size/Shape: Range from compact sensor housings to large network equipment

- Door Type: Hinged, lockable doors with gaskets provide weather sealing (IP65/IP66)

Stainless Steel Enclosures

Stainless steel's corrosion resistance and hygiene suit food processing, pharmaceuticals, marine, and outdoor applications. Its recyclability adds environmental benefits