Introduction

This article provides an in-depth examination of screw conveyors.

Continue reading to explore topics including:

- What are screw conveyors?

- Components of screw conveyors

- Screw conveyor configurations

- Screw conveyor considerations

- And much more...

Chapter 1: What are Screw Conveyors?

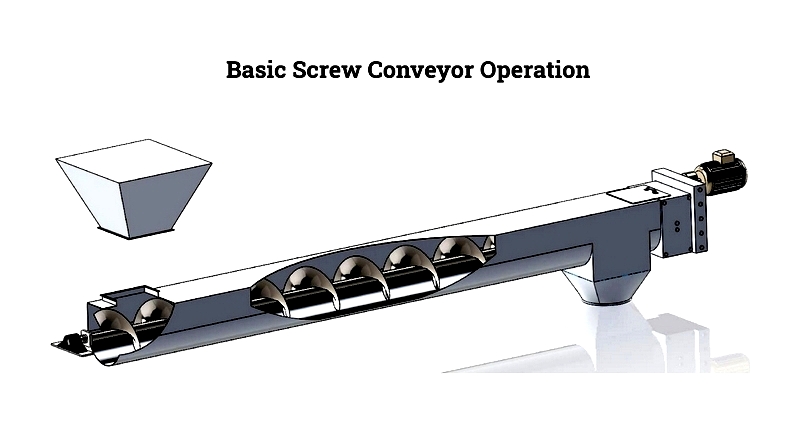

Screw conveyors, also known as auger conveyors, are industrial machines designed to efficiently transport large volumes of granular materials such as powders, grains, and granules. They can also handle semi-solids, liquids, and materials with poor flow characteristics. By eliminating manual material handling, they significantly enhance operational productivity. The basic components include a rotating screw shaft housed within a trough. As the shaft rotates, it moves materials along a straight path. Screw conveyors can be configured for horizontal, vertical, or inclined transportation.

Various screw conveyor types are engineered to handle different material properties. Bulk materials may be abrasive, non-flowing, fluidizable, moisture-absorbing (hygroscopic), or hazardous. Screw conveyors effectively transport products like cereals, fertilizers, animal feed, ash, gravel, cement, and solid waste.

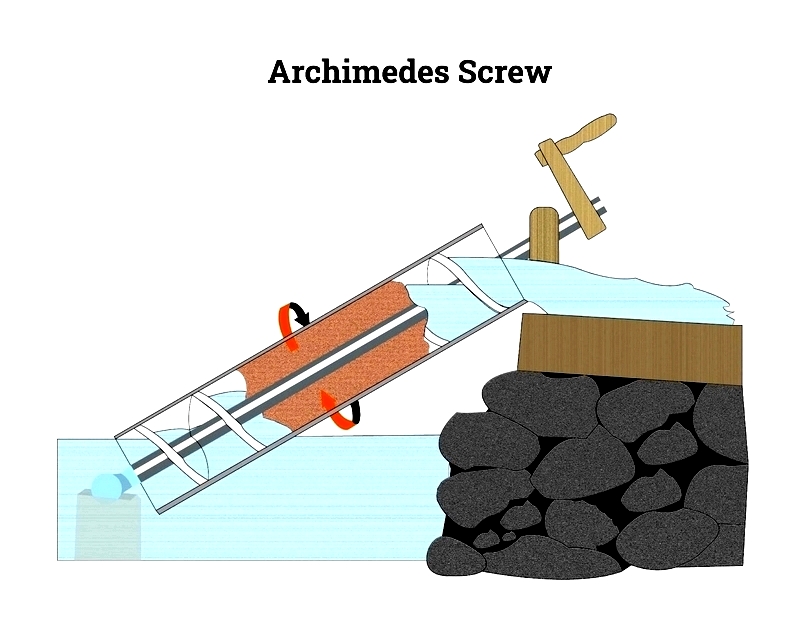

The Archimedes screw, dating back to around 250 B.C., represents the earliest form of screw conveyor. Originally developed as a simple positive displacement pump for lifting water to irrigation channels, its design and drive mechanisms have been refined over time to improve efficiency, durability, and speed while maintaining the original concept.

Chapter 2: Components of Screw Conveyors

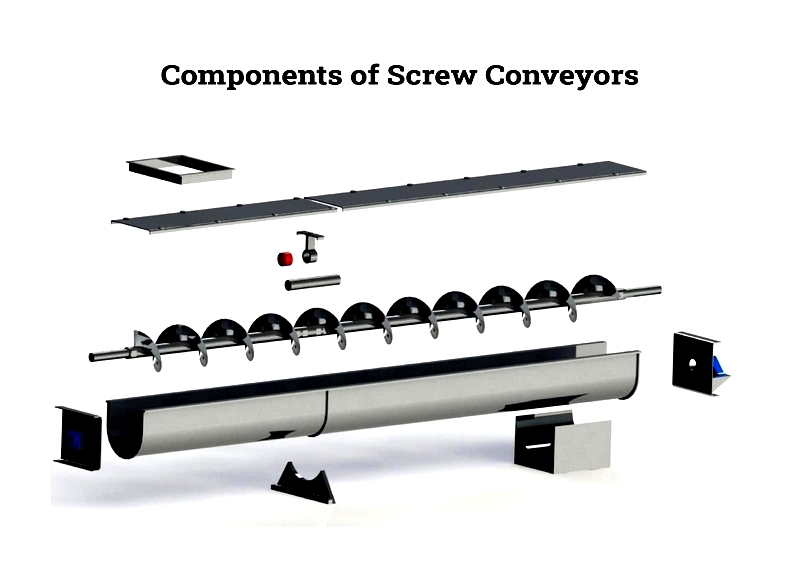

Screw conveyors are mechanical conveying systems widely used in agriculture, mining, chemical processing, food production, and bulk material handling for efficient transport of granular or powdered solids. Understanding their main components and design variations ensures optimal selection, operational efficiency, and reduced maintenance. Below we detail key screw conveyor parts and engineering variations for industry professionals evaluating conveyor solutions.

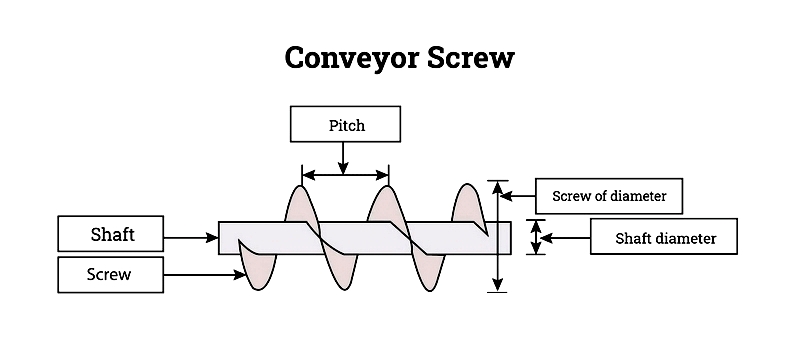

Conveyor Screw (Screw Blade or Helix)

The conveyor screw—also called the screw blade, auger, or helix—drives material movement along the trough. This rotating shaft features a helical blade (flight) that transports material from the feed to discharge point. Operating on the Archimedean principle, it moves material one pitch per rotation. The pitch is the axial distance between flight crests. Proper screw design ensures consistent flow, gentle handling, and minimal material degradation.

Screw conveyor types are classified by flight and pitch design:

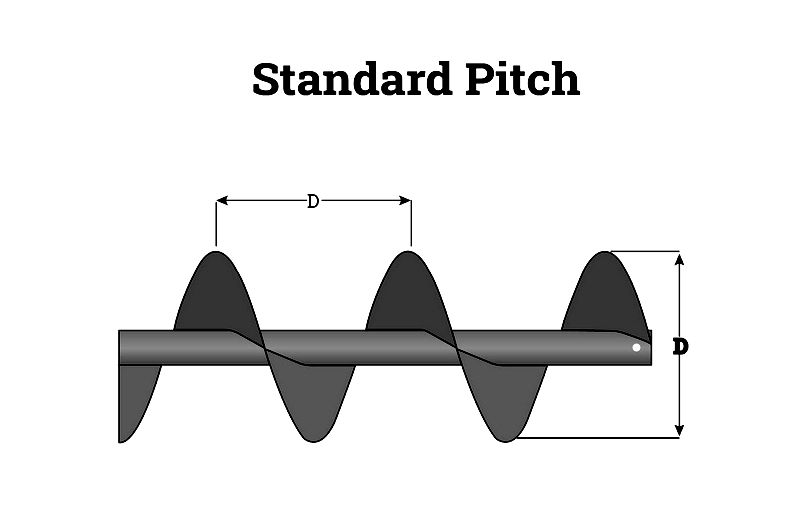

Standard Pitch Screw Conveyors

With pitch equal to screw diameter, these conveyors handle free-flowing or slightly sluggish materials in horizontal or low-angle (under 10°) installations. Common in grain handling and industrial processing, they provide reliable, uniform material flow.

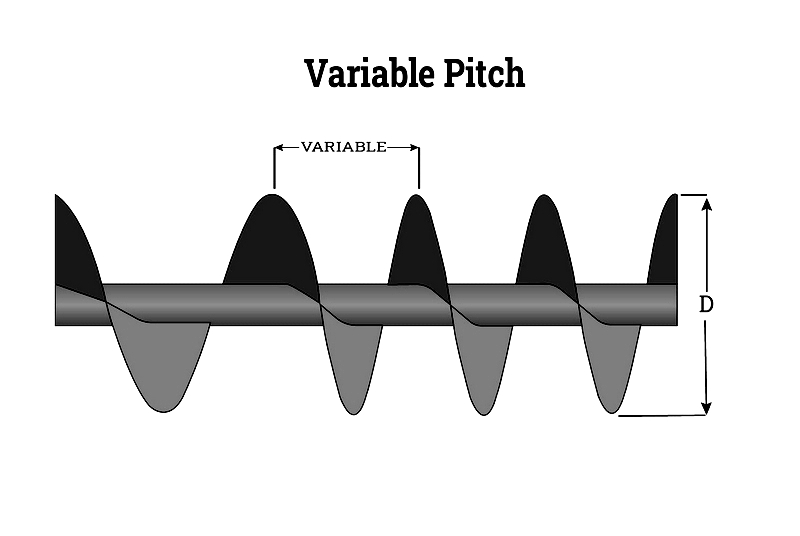

Variable Pitch Screw Conveyors

Featuring gradually increasing pitch from inlet to discharge, these designs enhance feed-end capacity and prevent material surges. Ideal for metering applications, they're used in plastics, food, and chemical industries for controlled feeding.

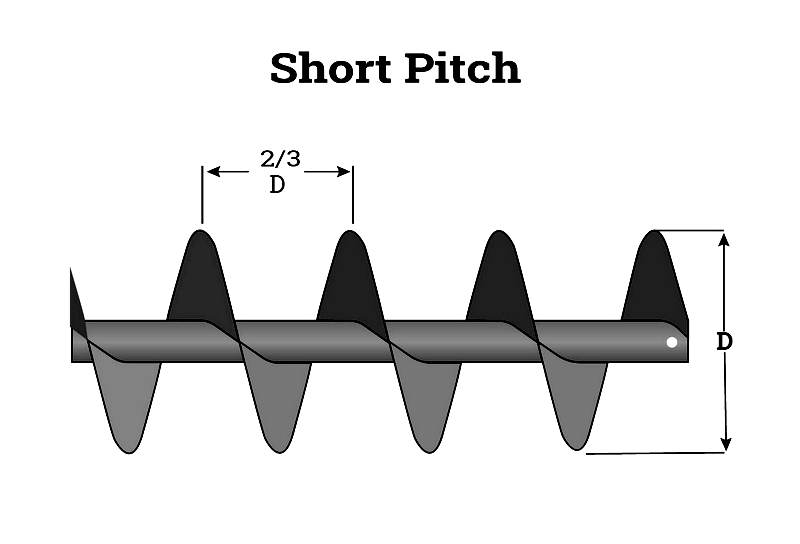

Short Pitch Screw Conveyors

With pitch two-thirds of screw diameter, these handle steep inclines or vertical lifts. They prevent material rollback in dry, free-flowing materials—suitable for mining and construction elevators.

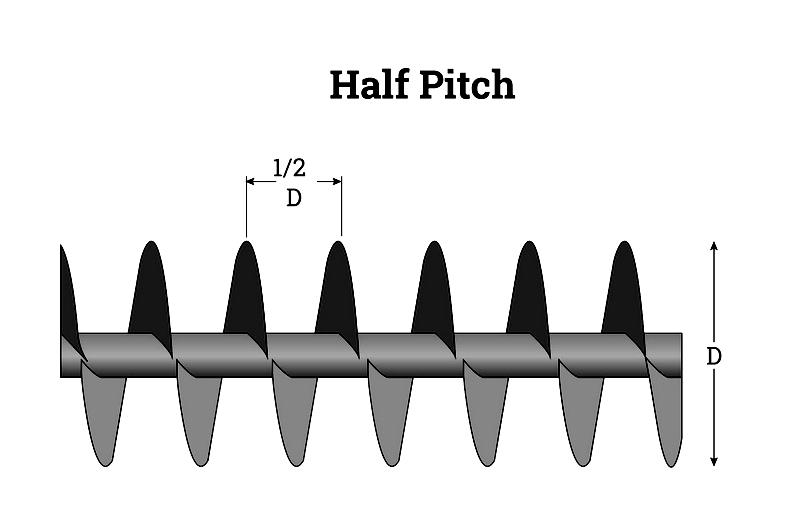

Half Pitch Screw Conveyors

Pitch equals half the screw diameter, countering gravity in vertical or inclined systems. Used in silo dischargers and feed dosing equipment.

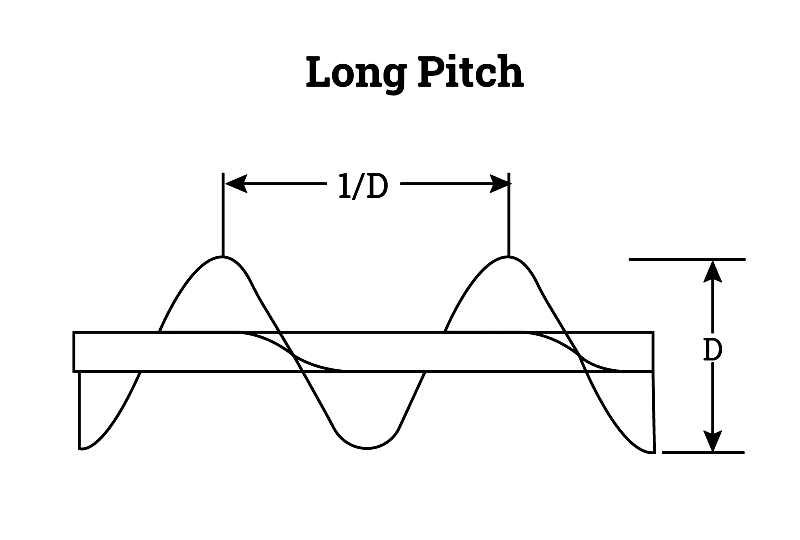

Long Pitch Screw Conveyors

Pitch 1.5 times screw diameter handles liquids, semi-fluids, or fluidized solids. Enable rapid transport with minimal energy in wastewater and pulp processing.

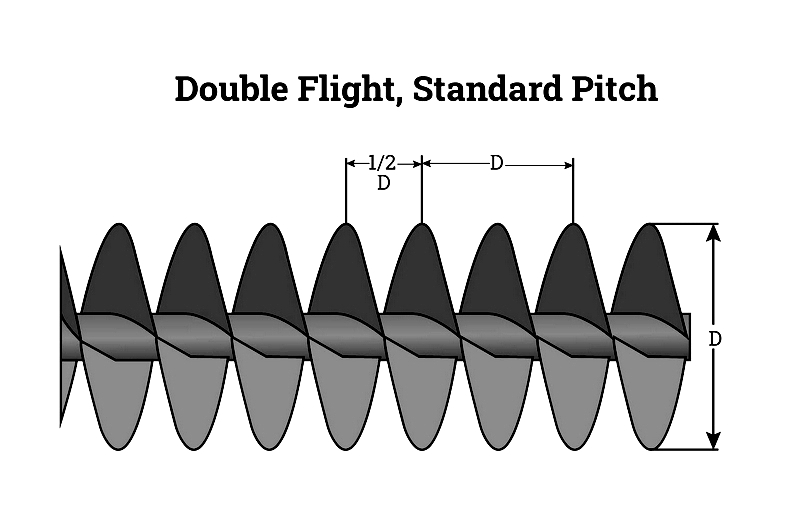

Double Flight Screw Conveyors

Dual helical flights (180° offset) double capacity per revolution. Provide stable flow in mixers and high-capacity conveying.

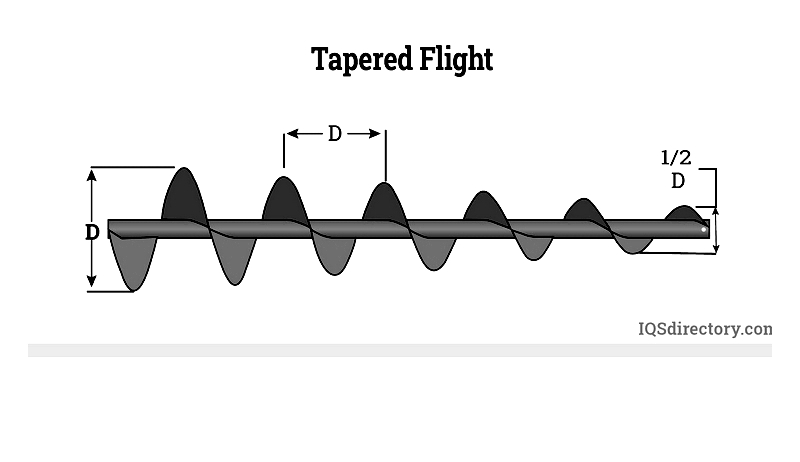

Tapered Flight Screw Conveyors

Gradually widening flights improve intake and distribution. Handle lumpy or bridge-prone materials in mineral processing.

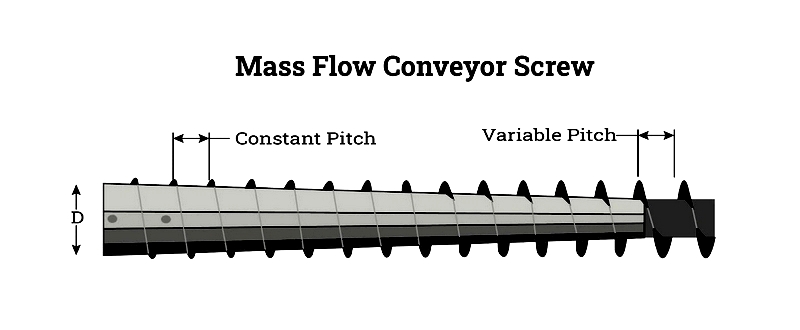

Mass Flow Screw Conveyors

Conical screw with variable pitch prevents material stagnation. Used under silos in cement and flour industries.

Flight fabrication methods:

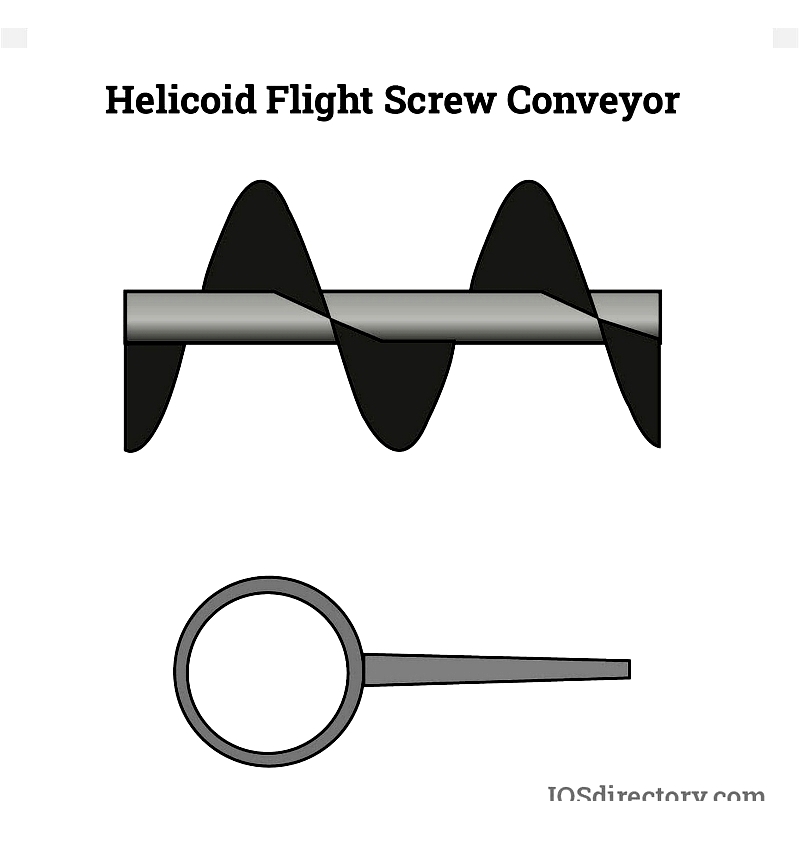

Helicoid Flight Screw Conveyors

Cold-rolled steel strips form durable, cost-effective flights for semi-abrasive materials like grain and cement.

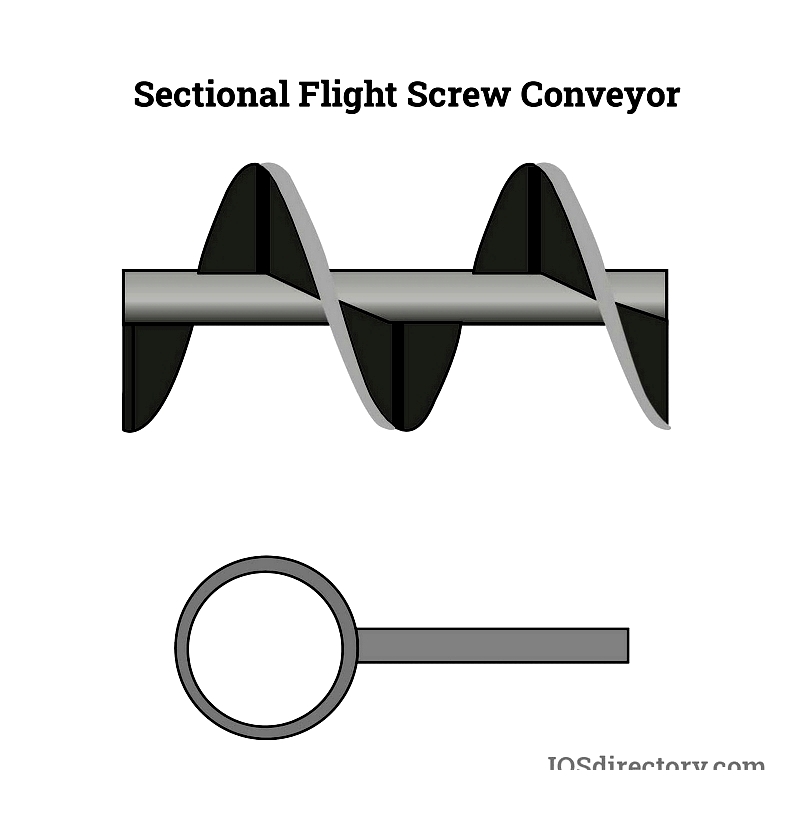

Sectional Flight Screw Conveyors

Custom steel discs welded to central pipe handle abrasive materials in harsh environments.

Specialty flight designs:

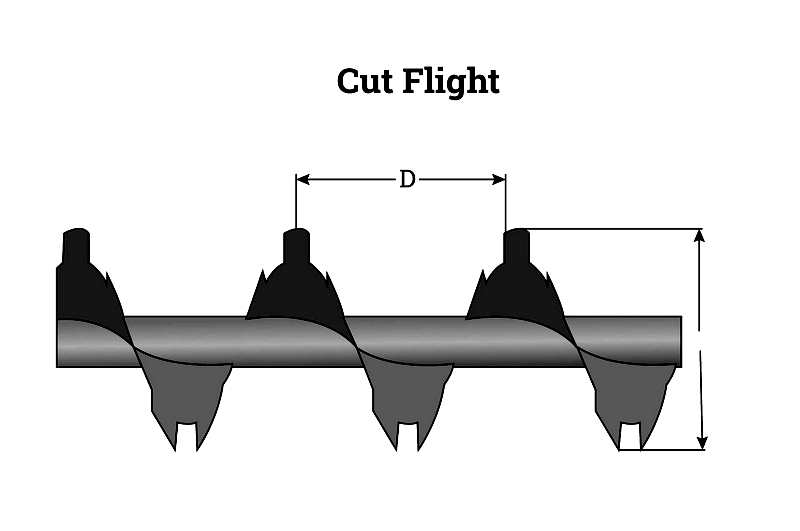

Cut Flight Screw Conveyors

Notched flights enhance mixing for sticky materials like hydrated lime.

Cut and Folded Flight Screw Conveyors

Notches with upturned folds optimize mixing for heat-sensitive powders.