Introduction

This article offers detailed insights into abrasive blasting and sandblasting machinery. You'll discover how these sandblasters are constructed, their building materials, as well as their applications, benefits, and limitations.

Continue reading to find answers to questions such as:

- How does sandblasting equipment function?

- Why choose sandblasting machinery over other cleaning and surface preparation tools?

- What capabilities does sandblasting machinery have? How can abrasive blasting equipment enhance manufacturing operations?

- How are sandblasters manufactured? What materials are used in their construction?

- What varieties and sizes of sandblasters do leading manufacturers provide?

- How should one select sandblasting machinery when placing an order or submitting an RFQ?

- Does blast media cause wear to sandblasting machinery components?

- And more...

I. Understanding Sandblasting Machinery

Sandblasting machinery encompasses various systems and components designed to propel blasting media onto surfaces for purposes like abrasion, cleaning, or surface modification. Different media types, including sand, abrasives, and metal shot, are driven by mechanisms such as pressurized water, compressed air, or blast wheels to perform these tasks effectively.

This equipment comes in multiple forms, such as:

- Industrial blast machines

- Abrasive impact cleaners

- Sandblasters

- Abrasive blasters

- Blast rooms

- Abrasive blast cabinets

- Air blasters

- Airless blasters

- Abrasive blasting rooms

- Blasting equipment

- Water blasters

- Portable blasters

- Wet blasters

- Dry blast cabinets

- Wheel blasting machinery

- Shot blasting equipment

- Micro-abrasive blast cabinets

- Micro-blasters

- Micro-jet machines

- Abrasive blast machines

- Shot peeners, media blasters

- Dry ice blasters

- Soda blasting equipment

- Peening machines

II. Types and Technologies of Sandblasting Equipment

Sandblasting Equipment Technology

To understand how sandblasters work, it's essential to grasp the advanced technology behind industrial blast equipment. Sandblasting, or abrasive blasting, is widely used in manufacturing, automotive restoration, surface preparation, shipbuilding, and metal finishing industries.

The technology used to propel blast media—whether through pneumatic air pressure or blast wheels—distinguishes different sandblasting equipment types. Choosing the right system is crucial for achieving desired surface roughness, coating adhesion, or contaminant removal.

Primary pneumatic propulsion technologies in blast machinery include:

Air or Dry Blast Equipment – Uses compressed air to propel media, categorized into suction (siphon) and direct pressure systems.

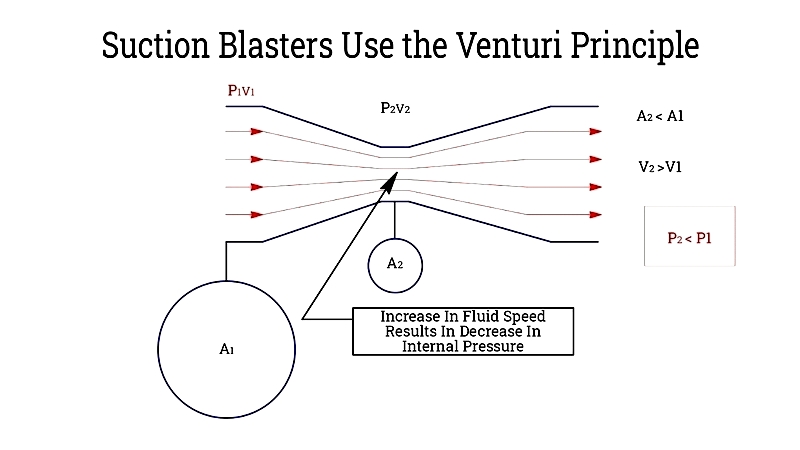

Suction or Siphon Blast Equipment – Employs the venturi siphon effect to draw abrasive into a pressurized stream, popular in automotive and light production environments.

Venturi devices create a vacuum to pull media into the stream, making them adaptable and cost-effective for entry-level applications.

Suction blasters are less aggressive than pressure systems, making them suitable for short-run projects, maintenance, and delicate tasks like glass etching.

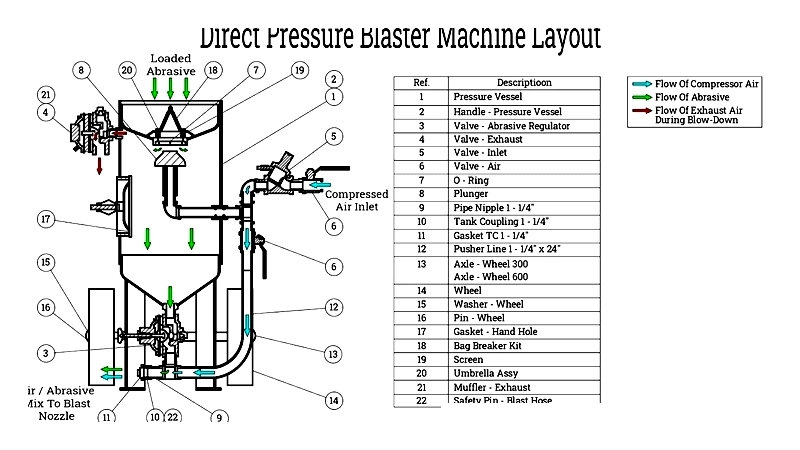

Direct Pressure Blast Equipment – Uses pressurized vessels to deliver media at higher speeds, ideal for industrial-scale cleaning and surface prep.

Pressure systems clean surfaces up to four times faster than suction blasters, making them essential for high-volume production.

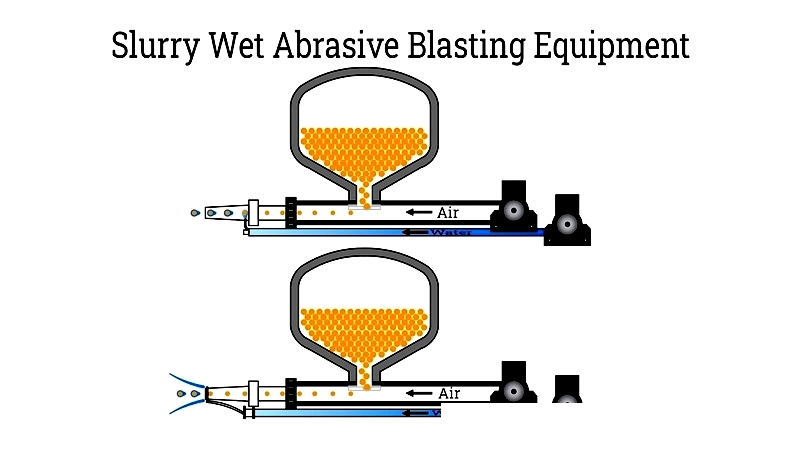

Wet Abrasive Blast Equipment – Uses water to propel media, reducing dust by over 90%. Ideal for hazardous material removal and heat-sensitive components.

Slurry Blasting Equipment – Combines water and media before the nozzle, offering dust control for masonry cleaning and corrosion control.

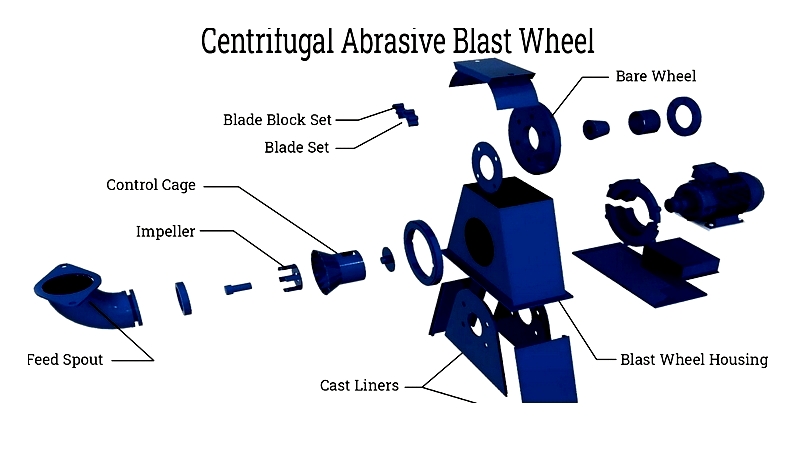

Wheel Blast Equipment – Uses centrifugal force for rapid, automated cleaning of large parts like castings and forgings.

Shot Peening Machines – Imparts compressive stresses to enhance fatigue resistance in aerospace and automotive components.

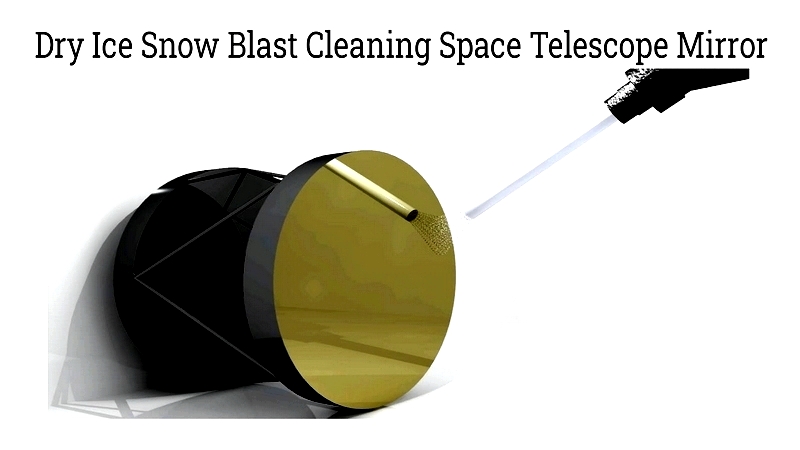

Ice Blasters – Use dry ice or water ice for residue-free cleaning, ideal for sensitive applications.

Sandblasting Machinery Types – By Size and Application

Modern sandblasting equipment ranges from benchtop micro-blasters to industrial-scale automated systems, tailored to specific needs.

Shop and Laboratory Sandblasting Machinery

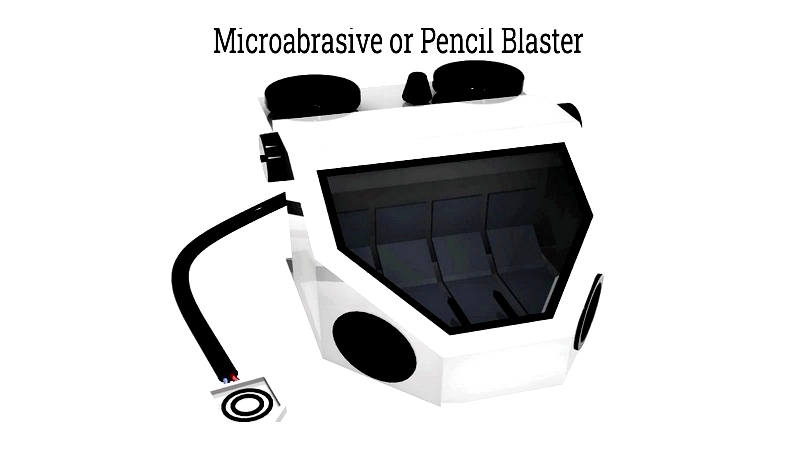

Benchtop Micro Blasters – Feature precision nozzles for delicate tasks in electronics, jewelry, and medical device manufacturing.

Manual Blast Cabinets – Provide contained environments for spot blasting and coating removal in auto shops and fabrication.

Production Sandblasting Machinery

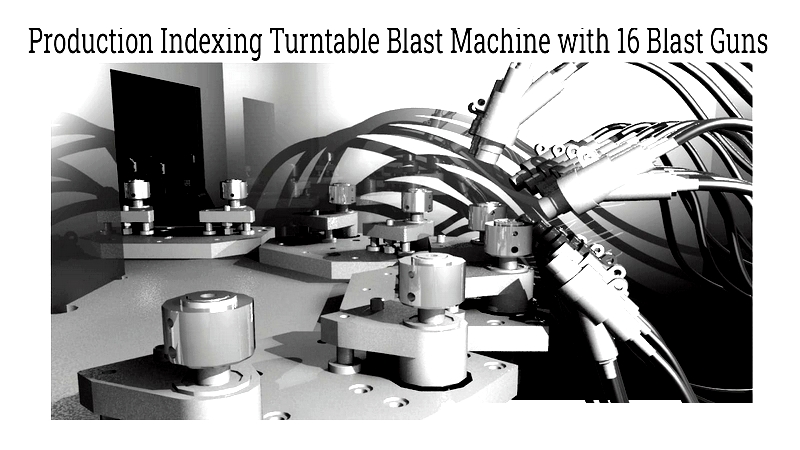

Production-grade systems handle large components or batches, integrating into automated lines for high-throughput operations.

Automated Blasting – Robotic systems ensure repeatability and reduce labor costs in aerospace and precision manufacturing.