Introduction

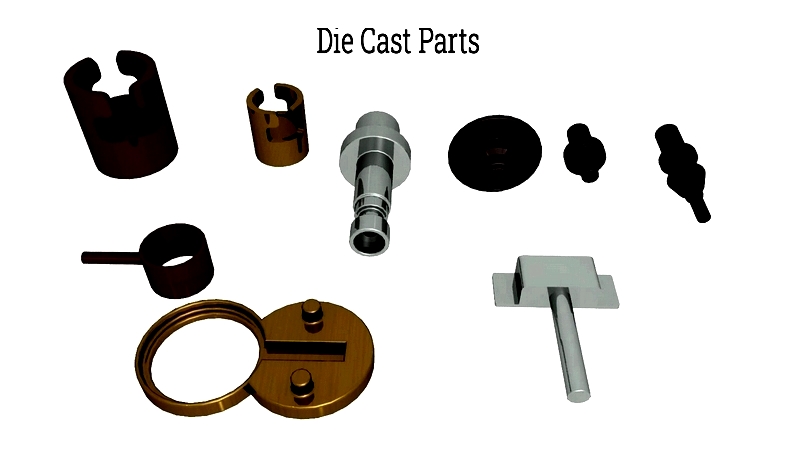

This section provides information about die casting and includes a list of die casting manufacturers.

You will learn about:

- The fundamentals of die casting

- Various metals used in die casting

- The production processes for die castings

- Hot and cold die casting methods

- Design geometry for die casting

- And additional related topics

Scroll down to begin exploring.

Chapter One – What is Die Casting?

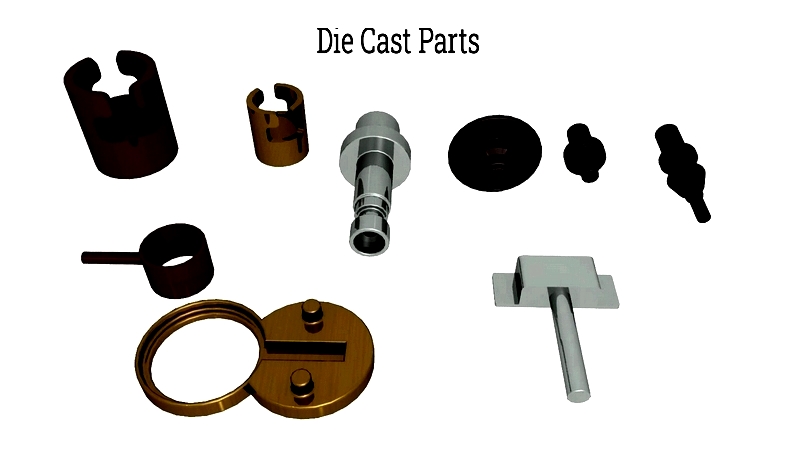

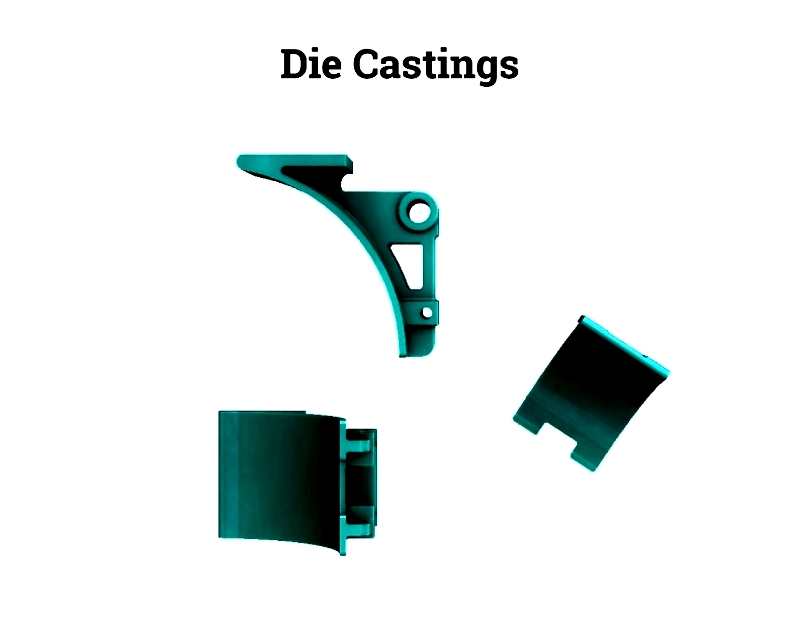

Die casting is a high-pressure metal casting process that injects molten metal into molds. This method creates dimensionally precise metal parts with excellent surface finishes. Its capacity for producing intricate components makes it ideal for mass production. Die castings are typically made from non-ferrous metals including zinc, copper, aluminum, magnesium, lead, pewter, and tin.

There are two primary die casting methods: hot chamber and cold chamber. The selection depends on the metal type and part requirements. Cold chamber casting is suitable for metals with high melting points like aluminum, brass, or copper alloys. Hot chamber casting is restricted to metals that remain stable when heated, such as zinc, lead, and magnesium alloys.

The die casting process is both efficient and economical, offering diverse shape possibilities. The resulting parts are durable and can be designed for aesthetic appeal, providing significant advantages for designers.

This high-speed process creates complex shapes with tight tolerances, often eliminating the need for post-production processing. Additional tooling or shaping is typically unnecessary. Finished parts exhibit heat resistance and high tensile strength.

Tolerances can reach +/-.002" for aluminum features and +/-.0005" for zinc components, depending on size and specifications.

Die Casting vs Forging

Die casting and forging represent distinct metalworking processes with notable differences.

Die casting injects molten metal into molds under high pressure, creating detailed shapes with excellent dimensional accuracy. This method excels at producing complex, thin-walled parts with smooth finishes, making it suitable for automotive components and consumer electronics.

Forging shapes metal through compressive forces at high temperatures, enhancing material strength and grain structure. This produces durable parts for heavy machinery, aerospace, and construction equipment. While die casting offers precision, forging provides superior strength and structural integrity.

Chapter Two – metals Used in Die Casting

Selecting the appropriate metal significantly affects product performance, durability, and cost-effectiveness. The choice depends on application requirements, weight considerations, corrosion resistance needs, and mechanical properties.

Aluminum die casting is popular for automotive components due to its excellent strength-to-weight ratio, light weight, and natural corrosion resistance. Stainless steel is preferred for medical instruments because of its biocompatibility, hygienic properties, and resistance to corrosion and oxidation.

Die casting alloys must maintain their properties throughout and after the melting process.

- Aluminum

- Zinc

- Brass

- Bronze

- Tin

- Lead

- Magnesium

- Silicon tombac

- Stainless steel

- Carbon steel

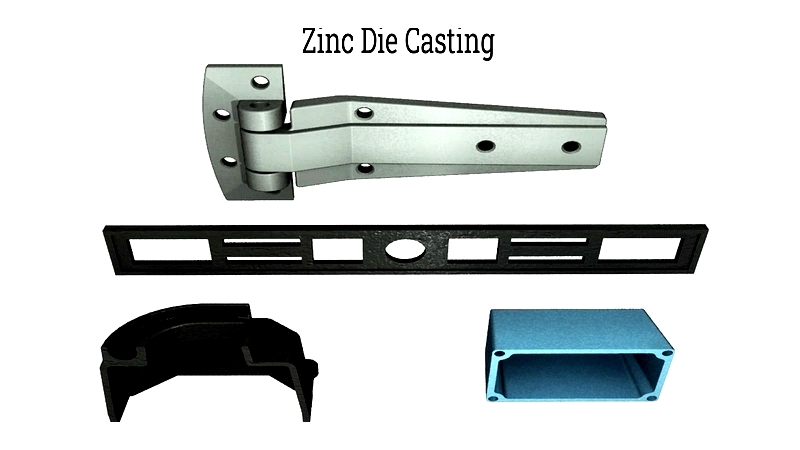

Zinc

Zinc is a versatile die casting metal offering an excellent balance of strength, ductility, and finishing options. Though 2.3 times heavier than aluminum, it's often chosen for intricate parts where superior surface finish and thin-wall capabilities are essential. Zinc casting produces accurate complex geometries, making it popular in electronics, automotive, and hardware applications.

Zinc alloys like ZAMAK demonstrate high ductility, impact strength, and plating compatibility, serving both decorative and functional purposes. The material's natural lubricity can eliminate the need for additional wear components in gears and housings. Zinc's low melting temperature reduces die wear, lowering production costs for large runs.

Zinc's excellent fluidity enables casting of fine details and thin walls (down to 0.025 inches), benefiting miniaturized electronics and medical devices. Lower casting temperatures minimize thermal shock, extending die life and improving productivity.

Disadvantages of Zinc

Zinc's relatively low melting point (approximately 419°C/786°F) limits its use in high-temperature applications compared to aluminum or magnesium.

While zinc castings achieve good finishes, they may require additional coatings for optimal corrosion resistance in certain environments.

Aluminum

Aluminum die casting is standard for high-volume production requiring lightweight, strong, corrosion-resistant components with good thermal conductivity. Alloys like A380 and ADC12 form complex thin-walled shapes, making them ideal for automotive, aerospace, and electronics applications where weight reduction is critical.

Aluminum's strength-to-weight ratio ensures components withstand demanding loads while minimizing mass. Its thermal and electrical conductivity suits heat sinks, LED housings, and battery enclosures. The natural oxide layer provides corrosion protection, extending component lifespan.

Disadvantages of Aluminum

Aluminum's high shrinkage rate during solidification may require secondary machining for tight tolerances. Some alloys can be brittle, increasing fracture risk in high-impact applications. The material is also prone to porosity if process parameters aren't optimized.

Brass

Brass is valued for its corrosion resistance, conductivity, and attractive appearance, making it suitable for decorative hardware, plumbing fittings, and electrical connectors. Its rust resistance benefits marine components and architectural fixtures in humid environments.

Brass's thermal conductivity advantages HVAC systems and electrical contacts. The alloy's strength and wear resistance suit high-cycle mechanical components requiring durability and precision.

Disadvantages

Brass casting requires precise temperature control, increasing process complexity. Issues like porosity and die adhesion demand expert handling. The alloy's lower melting point restricts use in high-stress, high-temperature applications where deformation may occur.

For extreme conditions, alternatives like bronze or specialty steels may be preferable.

Material selection is crucial for successful die casting. Alloys offer design flexibility and cost options. Manufacturers collaborate with clients to balance performance, durability, thermal properties, and corrosion resistance with cost considerations.

Different alloys have varying processing costs, with some requiring additional finishing. Product size and volume also affect costs.

Chapter Three – Die Casting – Hot and Cold

The primary die casting methods are hot and cold chamber. Hot chamber casting heats metal within the machine, while cold chamber casting heats metal externally before transfer. Both processes create complex shapes with tight tolerances, heat resistance, and high strength, typically requiring minimal additional processing.

Hot Chamber Die Casting Process

Hot chamber casting suits low-melting-point alloys like zinc, magnesium, and certain lead/tin alloys. The die consists of stationary and movable halves, with molten metal maintained in a connected holding pot. When the plunger lifts, metal flows into the shot chamber; downward plunger movement forces metal through the gooseneck into the die cavity, enabling rapid production cycles.