Introduction

This section provides explanations about plug-in transformers, lists of manufacturers, and describes their various applications.

You will learn about:

- The definition of Plug-In Transformers

- Working principles of Plug-In Transformers

- Common applications of Plug-In Transformers

- Relationship between Class 2 Transformers and Plug-In Transformers

- Additional relevant information

Chapter 1: What is a Plug-In Transformer?

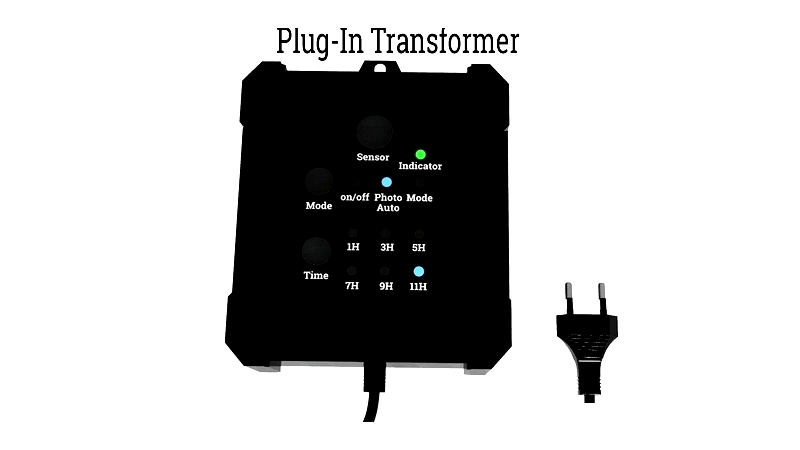

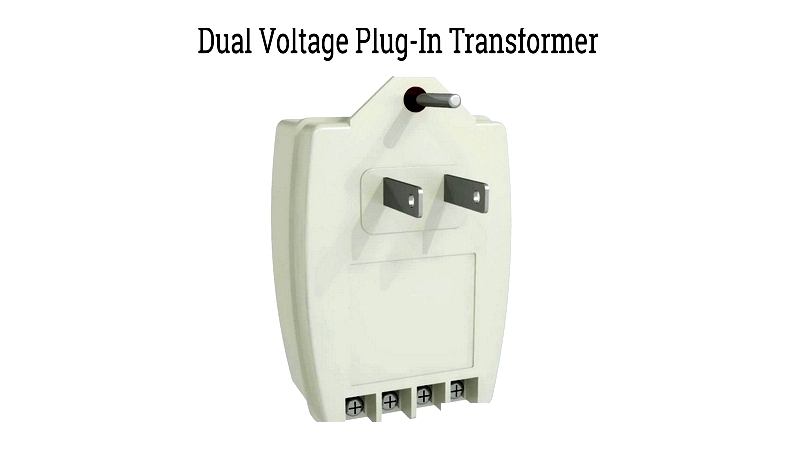

Plug-in transformers, categorized as Class 2 power supplies, are designed to connect to 15 amp, 120 or 240-volt alternating current (AC) branch circuits. Underwriters Laboratory (UL) 1310 defines the safety standards for Class 2 power units and battery chargers, ensuring user protection through rigorous requirements. These devices serve as AC adapters, power supplies, or Class 2 power units.

Plug-in transformers must meet three key limitations: they cannot exceed 100 VAS of continuous power output, must prevent excessive current during short circuits, and must maintain safety extra-low voltage (SELV) compliance with open circuit voltages not exceeding 90V DC or 42.4 V peak AC.

These compact transformers plug directly into wall outlets, providing low direct current voltages suitable for powering electronic devices. They protect low-voltage electronics from higher voltages and operate without cooling systems, resulting in smaller, lighter, and more space-efficient designs. This configuration minimizes heat impact on sensitive circuits while delivering lower power output.

Chapter 2: How Plug-In Transformers Work

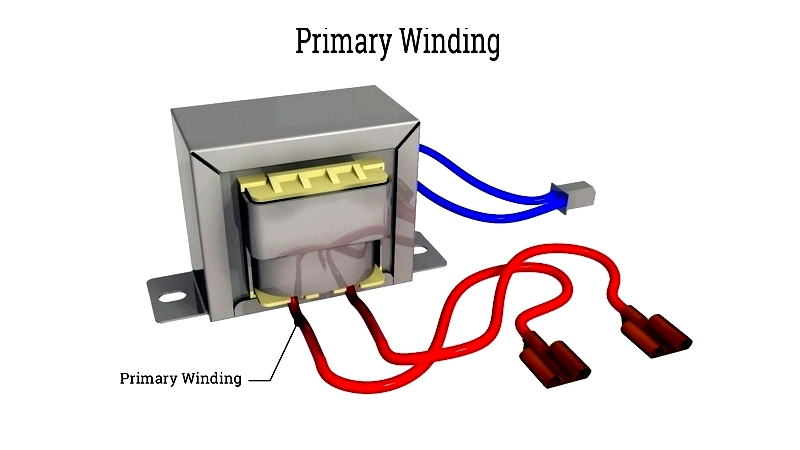

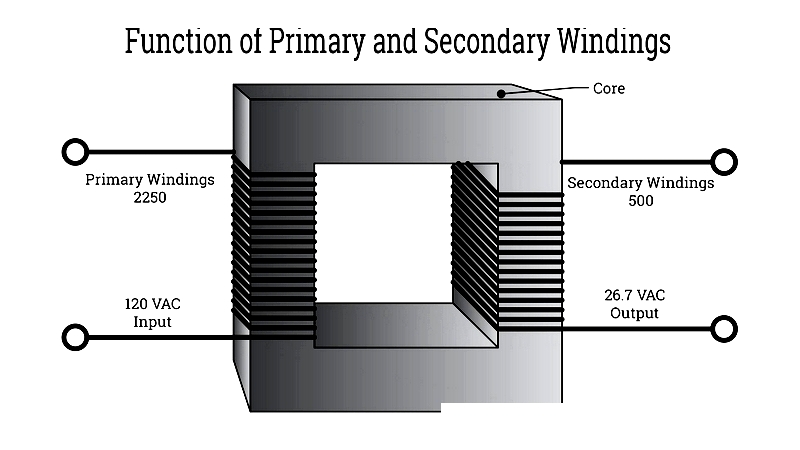

Plug-in transformers are electromagnetic devices that convert electrical power between different voltages, ensuring device safety and compatibility across various electrical systems. Found in household appliances, consumer electronics, and industrial automation, they provide essential voltage regulation, protection, and energy isolation. Their operation involves a magnetic core with primary and secondary wire windings. When AC flows through the primary winding, it creates a magnetic field that induces voltage in the secondary winding, enabling safe voltage conversion for connected devices.

Primary Winding

The primary winding receives input voltage (typically 120V AC in North America or 240V in Europe). The steel-laminated core enhances energy transfer while reducing losses. Current flow establishes a magnetic field necessary for induction in the secondary coil, with transformation efficiency depending on core performance.

Secondary Winding

The secondary winding delivers transformed voltage determined by the turns ratio between windings. This principle enables both step-down (for low-voltage devices) and step-up (for higher voltage requirements) transformations. For instance, a 2:1 turns ratio halves the input voltage, while more secondary turns can increase output.

The Core

The shared magnetic core facilitates efficient energy transfer between windings. Laminated or toroidal designs minimize energy loss, with materials like silicon steel and ferrite chosen for their magnetic properties. Core quality directly impacts efficiency, lifespan, and safety, with international standards ensuring reliability. Proper core selection addresses efficiency, noise, and thermal concerns during operation.

High-performance transformers may use grain-oriented laminated cores to further reduce losses. Magnetic permeability and low reluctance are critical for effective energy transfer, while proper material selection helps manage heat generation during extended use.

Wire Windings

Transformers typically use copper windings for superior conductivity, though aluminum offers a lighter alternative. Insulation prevents short circuits, with winding configurations affecting performance characteristics like frequency response and EMI shielding. The primary winding connects to power sources, while the secondary supplies connected devices, with design choices influencing isolation, regulation, and durability.

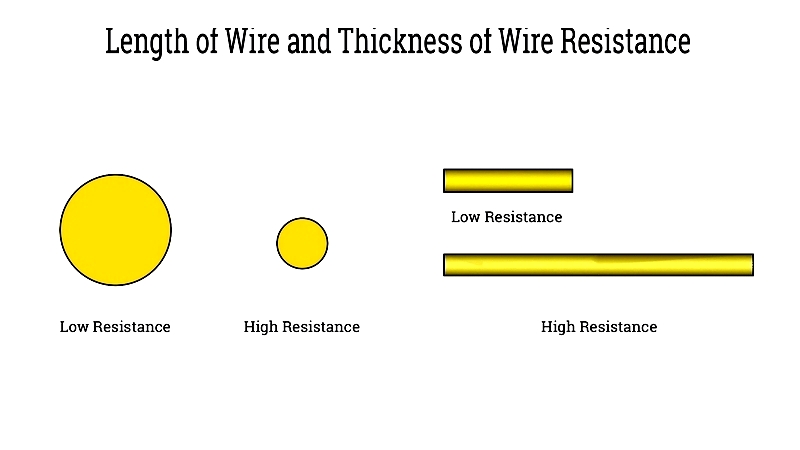

Wire Resistance

Measured in ohms, wire resistance affects current flow, voltage drop, and efficiency. Factors include material, length, temperature, and thickness. Longer or thinner wires increase resistance and heat, while thicker copper wires improve performance. Proper gauge selection is crucial, especially for high-current applications.

Temperature

Effective thermal management ensures transformer longevity and safety. Heat generation during operation requires proper insulation materials rated for specific temperature classes. Good thermal design extends product life and ensures safe continuous operation, with proper installation and maintenance further reducing overheating risks.