Introduction

Applications, types, processes, and manufacturers of air-to-air heat exchangers (AAHXs)

You will learn about:

- The definition of an Air-to-Air Heat Exchanger

- Manufacturing process of Air-to-Air Heat Exchangers

- Practical applications of Air-to-Air Heat Exchangers

- Different varieties of Air-to-Air Heat Exchangers

- Additional relevant information

Chapter 1: What is an Air-to-Air Heat Exchanger?

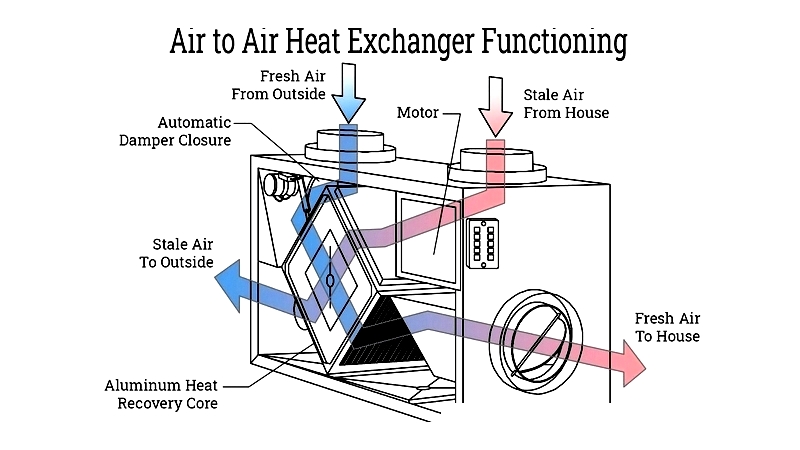

An air-to-air heat exchanger (AAHX) serves as a crucial component in balanced ventilation systems, transferring heat from warm exhaust air to incoming fresh air. This heat recovery process warms cold outside air using energy from expelled indoor air. The system operates through mechanical ventilation featuring two fans - one for supply and another for extraction - each connected to separate ducts. A heat transfer unit facilitates thermal exchange between these air streams.

These exchangers primarily function to dissipate equipment heat while introducing cooler air. Their closed-loop design efficiently cools various equipment types without compromising ambient air quality. Available in plate or shell-and-tube configurations, these systems distinguish themselves through their tubular or plate-based closed-loop structures. This configuration makes them particularly effective for applications requiring isolated cooling.

As an economical alternative to conventional air conditioning, air-to-air heat exchangers offer effective cooling where fans are unsuitable and traditional AC units prove impractical due to size constraints. Their self-contained design makes them ideal for sealed environments where maintaining air quality is paramount.

Chapter 2: Types of Air-to-Air Heat Exchangers

These systems provide cost-effective, quiet cooling solutions for enclosures, industrial processes, and commercial spaces. Unlike conventional AC systems, they transfer heat between separate airstreams without mixing them. The core component - a heat pipe containing specialized refrigerant - efficiently moves thermal energy from enclosures to cooler ambient air through phase-change processes, requiring minimal power input.

Various AAHX designs serve specific industrial and commercial HVAC needs. Industries ranging from manufacturing to food processing utilize these systems for energy recovery, pollution control, and climate management. By reclaiming ventilation heat that would otherwise be lost, organizations enhance energy efficiency, reduce operational costs, and improve sustainability.

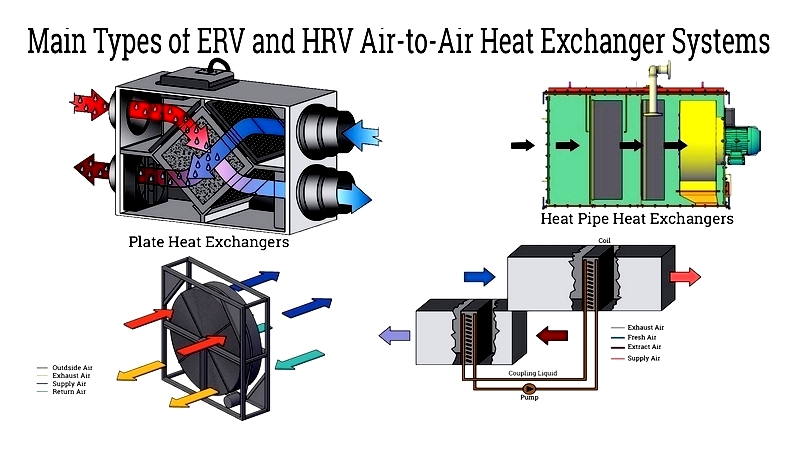

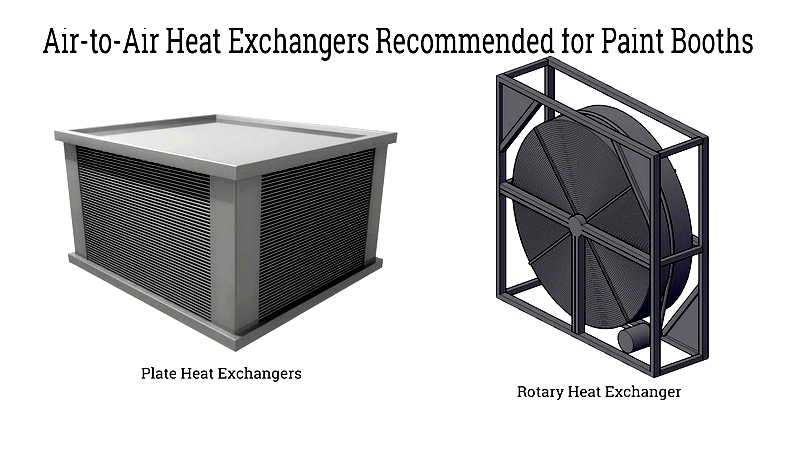

Classification depends on airflow patterns, heat transfer methods, and application requirements. The three main configurations are plate, tube, and rotary wheel exchangers, each offering distinct efficiency levels, pressure characteristics, and maintenance needs. Additional variants like run-around systems and energy recovery ventilators (ERVs) extend their utility across residential and industrial applications.

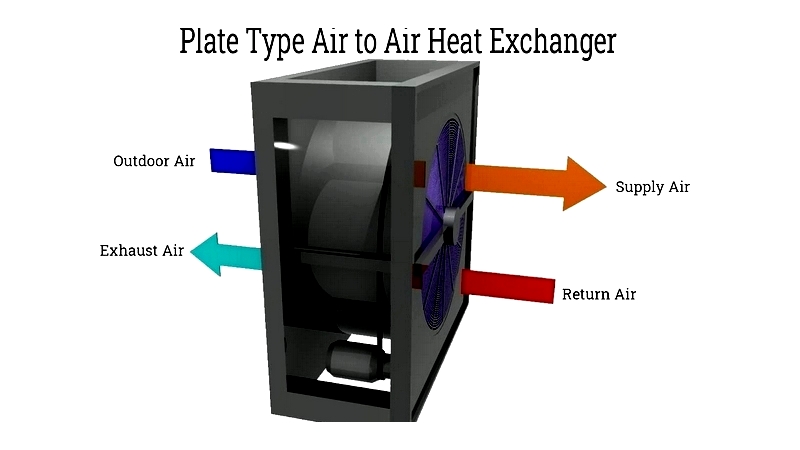

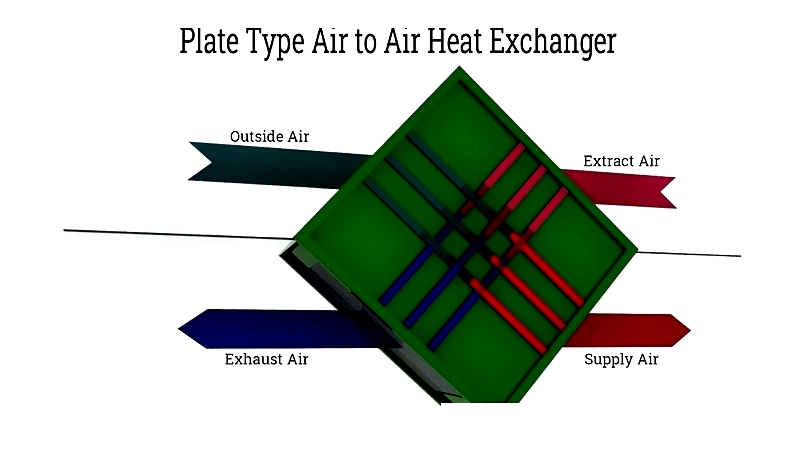

Plate Air-to-Air Heat Exchangers

Plate-type exchangers separate supply and exhaust streams using flat or profiled plates. This design prevents airstream mixing while enabling thermal transfer through plate conductivity - particularly important in healthcare and food production settings. Available in crossflow and counterflow arrangements, these units achieve 40-65% energy recovery efficiency.

Crossflow designs employ aluminum or stainless steel plates, offering economical, reliable solutions for hygienic environments. Counterflow configurations maximize temperature differentials for enhanced efficiency in large-scale ventilation systems. Advanced variants like dimple and wave plates improve turbulence and heat transfer while reducing maintenance needs.

Dimple plate designs withstand harsh industrial conditions while optimizing heat transfer. Their textured surfaces promote turbulent airflow with minimal pressure drop. Wave plate exchangers combine multiple surface patterns for superior performance, eliminating gasket requirements and preventing leaks. These corrosion-resistant units offer 3-4 times better efficiency than standard flat-plate models.

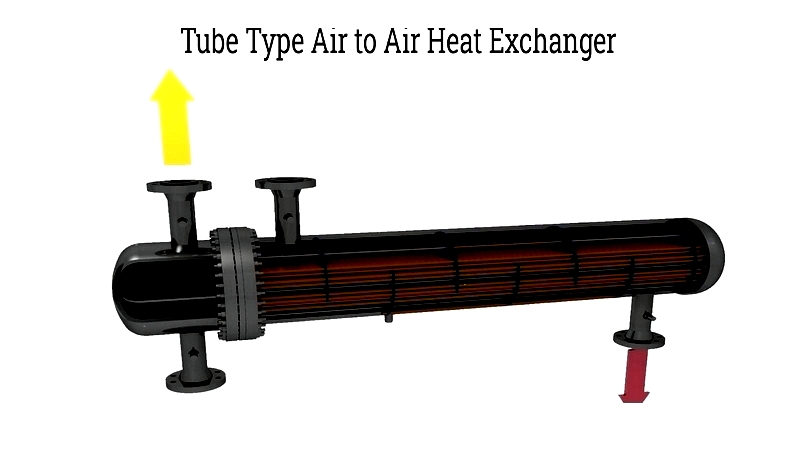

Tube Air-to-Air Heat Exchangers

Tube-type units utilize refrigerant-filled heat pipes for passive thermal transport. The phase-change cycle within sealed tubes enables efficient heat movement. Optional fans can enhance forced convection for precise temperature control. Their rugged construction suits dusty or chemically aggressive environments, with various tube configurations available for specific applications.

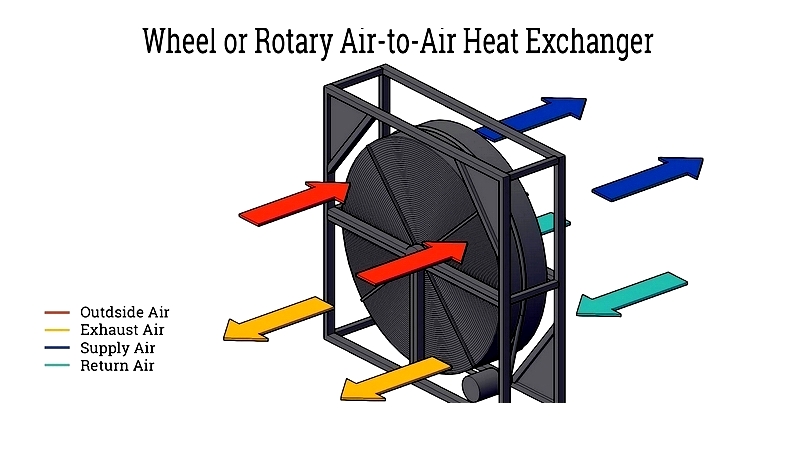

Thermal Wheel Air-to-Air Heat Exchangers

Rotary wheel exchangers employ rotating metal wheels for energy recovery. Available as heat wheels (sensible heat only) or enthalpy wheels (sensible plus latent heat), these systems excel in large commercial applications. Hygroscopic coatings enable simultaneous temperature and humidity control, improving indoor air quality while reducing HVAC loads.

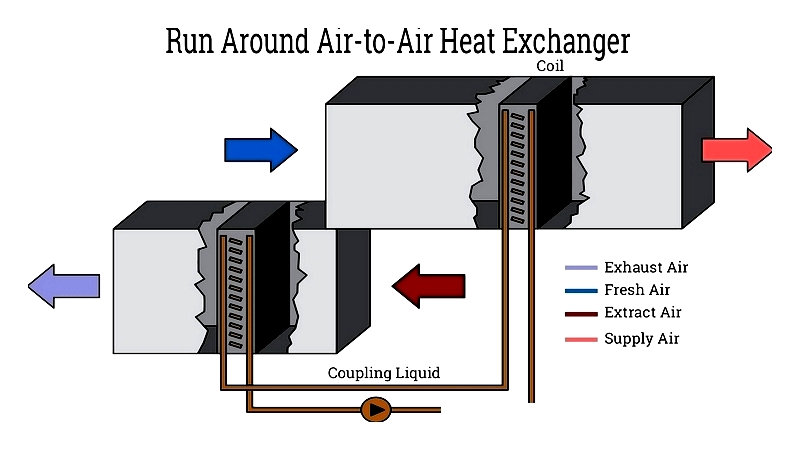

Run Around Air-to-Air Heat Exchangers

These systems use separated coils connected by a glycol loop, ideal for physically distant airstreams. Finned tube coils facilitate indirect heat transfer, with anti-freeze protection for cold climates. Their contamination-resistant design suits hospitals, labs, and industrial facilities requiring strict air separation.

Energy Recovery Ventilators (ERVs)

ERVs integrate AAHX technology into complete HVAC systems, recovering both sensible and latent heat. These units reduce energy consumption while maintaining ventilation requirements, complying with green building standards. Advanced models incorporate smart controls and filtration for optimal performance.

Chapter 3: Applications of Air-to-Air Heat Exchangers

These systems find widespread use across various industries due to their energy efficiency, cost-effectiveness, and air quality benefits. They're particularly valuable in sealed environments requiring temperature control without air stream mixing.

Electrical Control Panels

Protecting sensitive electronics from overheating, these exchangers maintain optimal enclosure temperatures while preventing contaminant entry. They reduce active cooling needs, lowering energy costs and improving reliability.

Automotive Industry

In paint booths, these systems recover heat from curing processes, preheating incoming air. Both plate and rotary designs are employed, reducing energy use and emissions while maintaining booth conditions.

Wood Processing

Crossflow exchangers improve kiln efficiency by preheating incoming air with exhaust heat. This reduces