Introduction

This article provides an in-depth exploration of tumbling machines.

It covers detailed information on various topics including:

- Tumbling Machine Principles

- Tumbling Machine Processes

- Types of Tumbling Machines and Media

- Applications and Advantages of Tumbling Machines

- And More...

Chapter 1: Understanding Tumbling Machine Principles

This section examines tumbling machines, describing their components, operation, and complete processing cycle.

What is a Tumbling Machine?

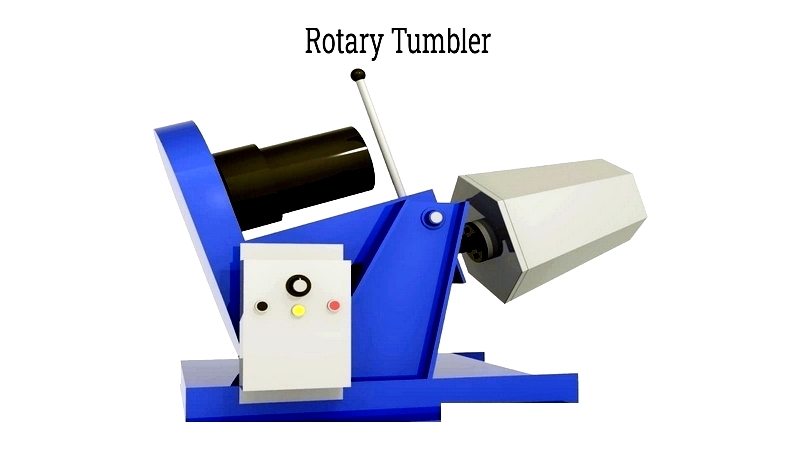

A tumbling machine is a robust piece of equipment designed for deburring and polishing metals, suitable for finishing both large components and multiple small parts. Also known as barreling or mass-finishing machines, they operate by rotating parts inside a multi-sided, urethane-coated barrel containing processing media and liquid compounds, effectively removing burrs through tumbling action.

The process occurs as the media's top layer continuously slides down the inclined surface created by the rotating barrel. These machines are widely used in jewelry manufacturing for stone tumbling, jewelry polishing, and metal part deburring. The most common types are rotary barrel and vibratory tumbling machines.

Key Components of a Tumbling Machine

Tumbling machines consist of several essential elements:

Machine Structure

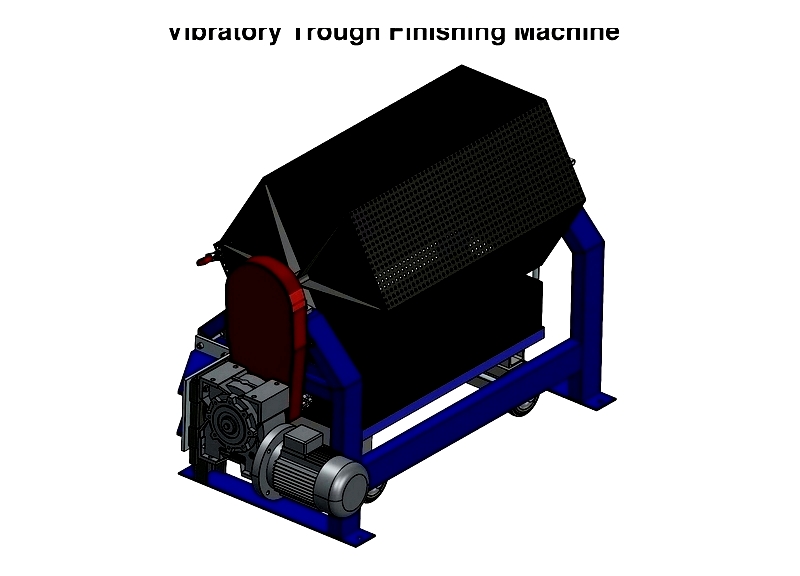

This includes the vibratory tub, motor, control panel, and spring system. These components work together to generate the vibratory motion needed for the finishing process.

Water Usage

Water plays a crucial role in wet deburring by reducing friction between parts and media. It also helps remove dirt and grease while washing away debris, resulting in cleaner components.

Media

Made from various abrasive materials, media are added to the bowl with parts to optimize polishing or deburring. The media's abrasive content determines deburring effectiveness.

Compounds

Compounds are mixed with media to enhance polishing or perform specific functions. Typically liquid-based (sometimes paste), certain compounds can also prevent corrosion.

How Tumbling Machines Operate

These machines contain barrels filled with media, abrasives, and workpieces. The barrel's consistent rotation creates friction that grinds, smooths, and polishes component surfaces.

Different materials require specific cycles. Hard materials need specialized media and abrasives distinct from softer materials. The mechanical surface treatment depends on the deburring media type and quantity, whether using vibration or rotation.

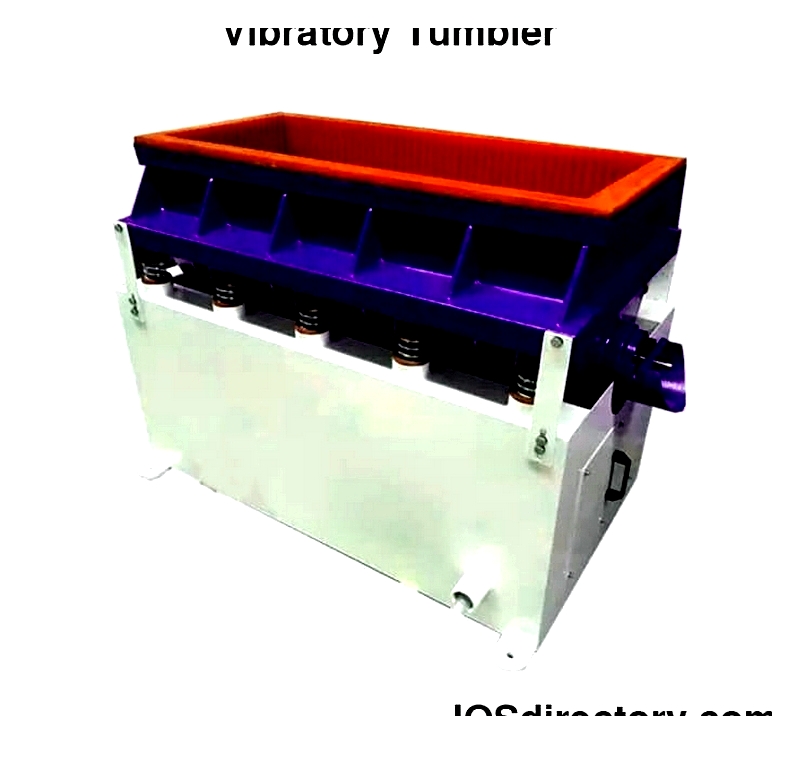

Vibratory Deburring Machine Functionality

These machines feature a polyurethane-lined circular tumbler holding parts and media. A motor powers the unit while springs provide stability. When activated, the bowl vibrates to initiate the finishing process.

Inside the bowl, media rubs against parts to facilitate finishing. The vibratory motion deburrs components while the toroidal movement ensures thorough cleaning, deburring, and polishing.

Chapter 2: Tumbling Machine Processes

Tumbling is a vital industrial surface finishing process that removes imperfections, burrs, and sharp edges from machined components. It's also widely used to polish surfaces, enhancing appearance, smoothness, and part performance.

Industrial tumbling and vibratory finishing processes deburr, round edges, clean, descale, and polish metal alloys, plastics, natural materials, and precious metals. These mass finishing systems are indispensable in aerospace, automotive, medical device, jewelry, and electronics industries for improving quality, corrosion resistance, and manufacturing efficiency.

Vibratory Tumbling

The vibratory tumbling process is a versatile surface finishing method. These machines create smooth, clean surfaces on plastic and metal parts using water and abrasive media (ceramic, plastic, or stainless steel) in specialized vibratory tumblers.

Vibratory machines generate high-frequency, low-amplitude vibrations causing media and parts to rub together. This produces consistent abrasion for efficient deburring, descaling, or polishing. The process handles delicate plastics and heavy metals alike, with equipment ranging from benchtop units to large industrial systems for high-volume production.

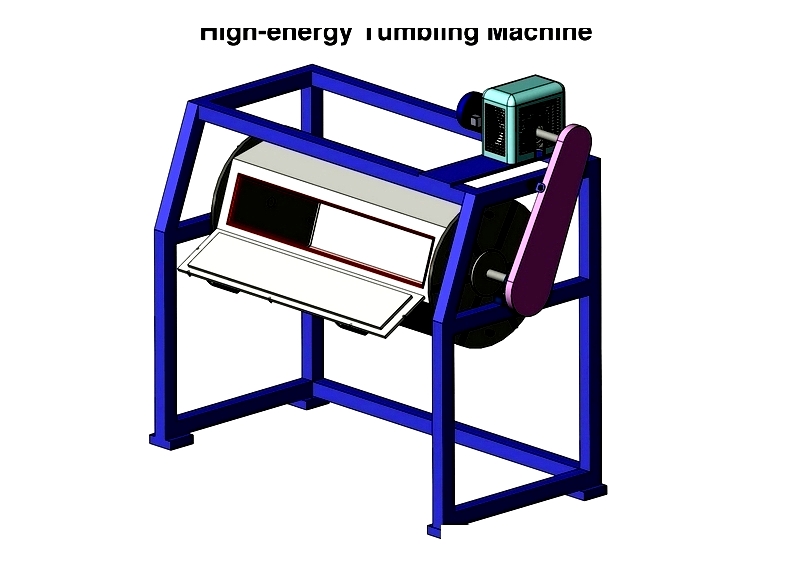

High-Energy Tumbling

High-energy tumbling (centrifugal barrel finishing) achieves smooth surfaces faster than conventional methods. Like vibratory tumbling, it uses water and abrasives but with greater rotational forces.

Sealed barrels containing parts, water, and media rotate on a carousel spinning in the opposite direction, creating intense centrifugal forces for rapid material removal and surface refinement. Ideal for precision deburring and small complex parts, these machines serve medical, aerospace, and metalworking sectors.

Comparing Vibratory and High-Energy Tumbling

High-energy tumbling offers faster cycle times but less automation than vibratory tumbling. Vibratory systems provide continuous automated processing for larger volumes, while high-energy machines excel at precision finishing for small, intricate components.

Vibratory equipment often features advanced controls for consistent results, while high-energy systems prioritize precision finishing for high-value parts. Both methods reduce rejects, extend part life, and meet industry finish standards.

Tumbling-Vibro Finishing Stages

This four-stage process achieves flawless surfaces:

- Grinding: Removes major imperfections and burrs

- Smoothing: Addresses minor surface defects

- Polishing: Refines surfaces with fine abrasives

- Shining: Produces brilliant reflective finishes

This sequence ensures parts meet both aesthetic and functional requirements across critical industries.

Materials Suitable for Tumbling

Tumbling machines process diverse materials including:

- Plastics (nylon, PMMA, polyesters, cellulose acetate)

- Natural materials (wood, corozo, horn, mother-of-pearl)

- Precious metals (gold, silver, platinum for jewelry/coins)

- metal alloys (stainless steel, aluminum, brass, copper, titanium, zinc)

Optimal results require proper machine selection, media choice, and process parameters. Manufacturers often experiment with media