Introduction

This is the most comprehensive online guide about centrifuges. You will learn:

- Working Principles of Centrifuges

- Centrifuge Classifications and Types

- Applications and Advantages of Centrifuges

- And much more...

Chapter 1: Understanding Centrifuge Operating Principles

This chapter explains fundamental centrifuge concepts, including their design, construction, and core operational mechanisms.

What is a Centrifuge?

A centrifuge is a scientific instrument that separates fluids, gases, or liquids based on density differences. Separation occurs when the sample container spins rapidly, generating centrifugal force that pushes denser materials toward the container's base.

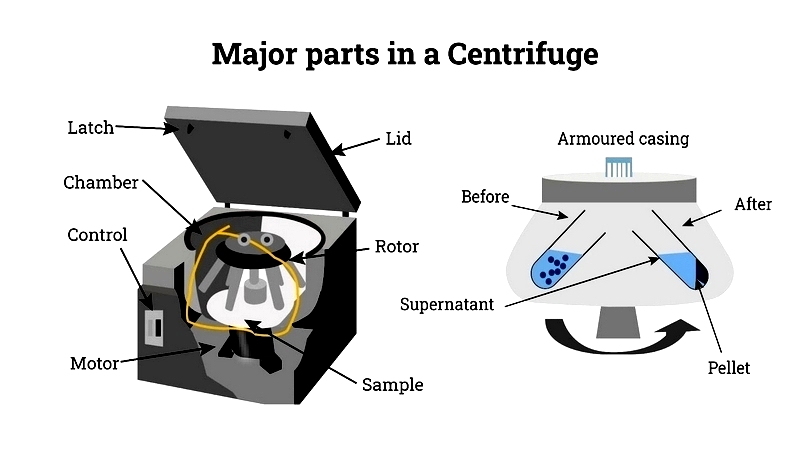

Centrifuge Construction

Laboratory centrifuges use rotating rotors to create centrifugal force, separating particles of different sizes in solutions. These devices are widely used in pharmaceuticals, food testing, environmental protection, and chemical analysis.

Designed for user convenience, centrifuges feature adjustable speed and temperature controls. A standard laboratory centrifuge includes these components:

Main Structure

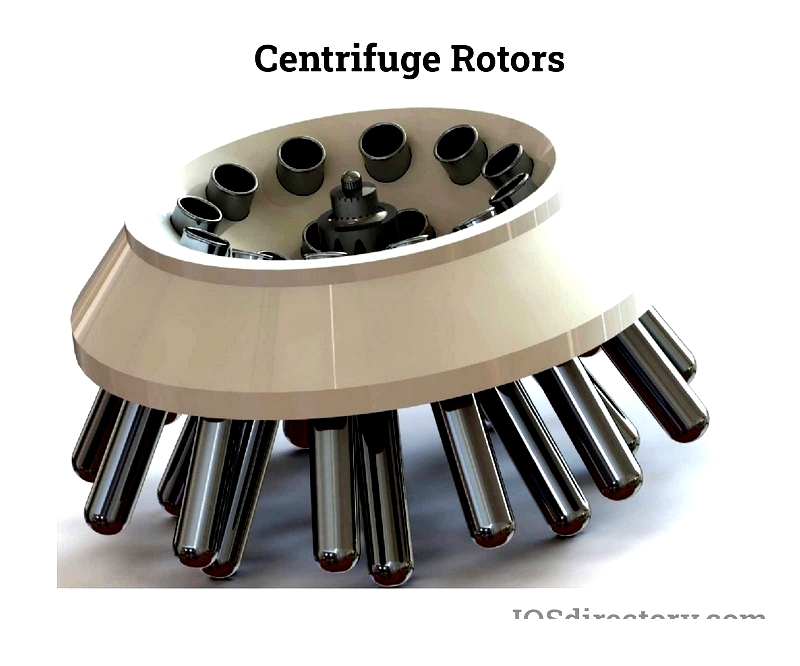

Rotors come in angular and horizontal designs, each suited for specific speed and capacity requirements. Horizontal rotors offer greater resistance, making them better for large-volume separations rather than high-speed applications.

Rotating Systems (Rotor)

Centrifuge rotors enable high-speed separation but typically handle smaller volumes. Horizontal rotors provide more resistance, making them ideal for processing larger quantities rather than rapid separations.

Drive Mechanism

The drive system consists of a motor, drive shaft, and damping unit. The AC-powered motor rotates a lubricated shaft while the damping system minimizes vibration and noise for smooth operation.

Control Interface

Microcomputer-controlled with touchscreen displays, this system allows operators to adjust spin speed and centrifugal force, with programmable settings for repeat experiments.

Cooling System

The refrigeration unit uses a sealed Copeland Compressor with separate cooling and heating circuits.

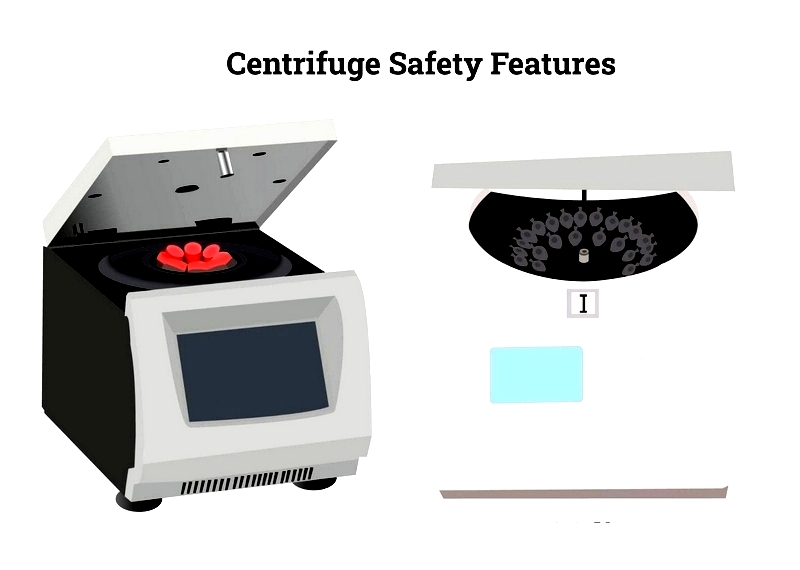

Safety Features

Protections include current, temperature, speed, balance, and door cover safety mechanisms.

Centrifuge Operation

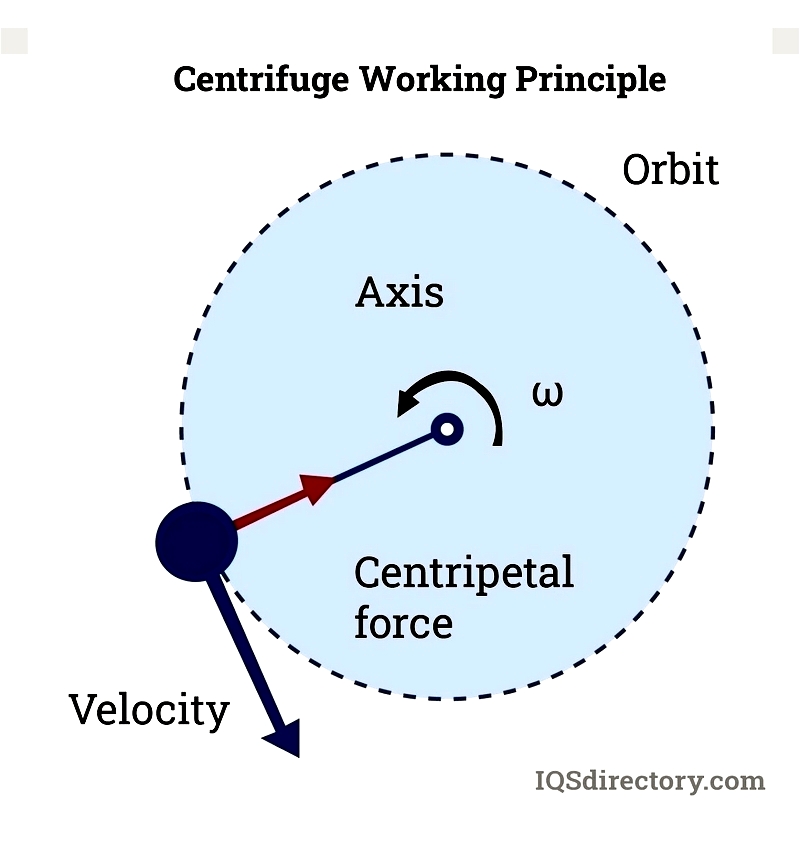

Particles separate by density under centrifugal force, with denser materials moving outward while lighter components remain near the center. When density differences are small, increased centrifugal force enhances separation.

Centrifuges spin samples around a fixed axis, creating centripetal acceleration that drives dense particles toward the container walls. In lab settings, tube samples show dense particles at the bottom with lighter materials above.

Operational Principles

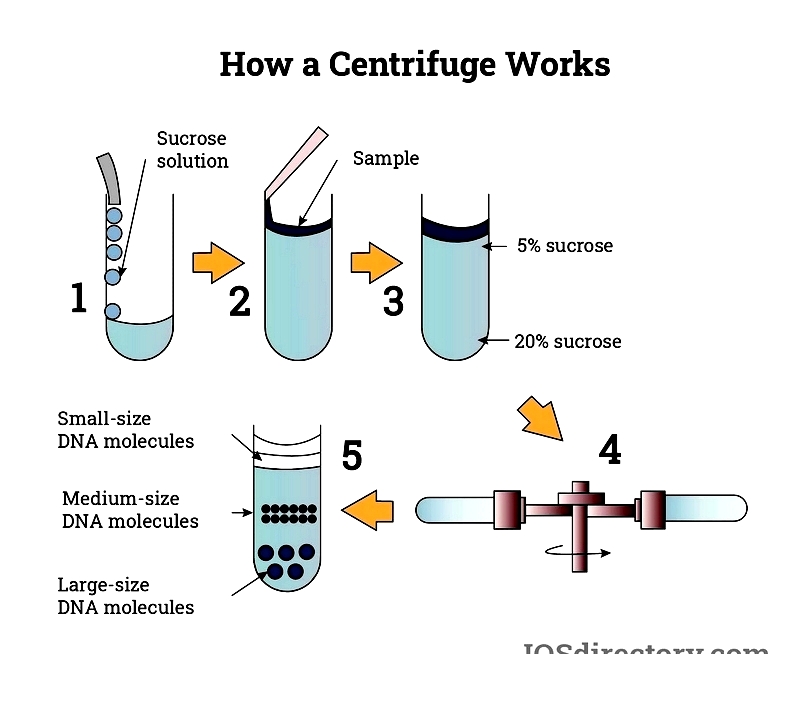

Centrifuges combine gravitational and centrifugal forces for density-based separation. Common techniques include pelleting, density gradient separation, and phase separation. Pelleting concentrates particles at the tube bottom as a pellet separate from the supernatant.

Ultrafiltration uses membranes for molecular separation. Isopycnic centrifugation achieves equilibrium when particles match solution density, with forces measured in gravity units for precision.

Centrifuge Key Features

Selecting the right laboratory centrifuge requires evaluating these characteristics:

Maximum RPM and RCF

These determine spinning capability and force intensity. Relative centrifugal force (RCF) measures the force applied to samples. Many centrifuges reach 14,000 RPM with 18,624 RCF.

Rotor Types

Different centrifuge models offer specific rotor configurations considering:

Vessel Compatibility

Rotors must accommodate intended sample containers in required sizes.

Rotor Design

Options include fixed-angle, swing-out, vertical, PCR strip, and microlite rotors.

Maximum RCF

Verify the centrifuge achieves necessary separation forces.

Temperature Range

Some centrifuges operate at room temperature while others cool samples to -10°C or -20°C.

Safety Features

Modern centrifuges incorporate multiple safety systems:

Electric Lid Lock

Secures the lid during operation to prevent accidental opening.

Imbalance Detection

Automatically stops operation if excessive vibration occurs.

Sealed Rotors

Prevent biohazard leaks during centrifugation.

Rotor Identification

Detects rotor type and enforces safe speed limits.

Placement and Noise

Install centrifuges on stable surfaces and consider noise levels in lab placement.

Centrifuge Components

All centrifuges contain two main parts: the rotor assembly and electric motor. The rotor creates spinning motion while the motor converts electrical energy to mechanical force.

Chapter 2: Centrifuge Classifications and Types

This chapter examines centrifuge categories, designs, applications, and industry-specific uses to help select appropriate equipment for laboratory, industrial, or processing needs.

Centrifuge Classification

Centrifuges are primarily divided into low-speed and high-speed types, distinguished by rotational speed, capacity, technology, and applications. Understanding these categories helps professionals choose suitable equipment for sample processing, material separation, or particle classification.

Low-Speed Centrifuge

Essential for clinical labs and education, low-speed centrifuges operate at 4,000-5,000 RPM for routine sedimentation. They typically use fixed-angle or swinging bucket rotors for blood fractionation, biochemical assays, and basic particle separation.

High-Speed Centrifuge

High-speed centrifuges (15,000-20,000 RPM) are used in advanced applications like cell organelle separation, DNA/RNA extraction, and pharmaceutical research. They feature precise temperature/speed controls and accommodate fixed-angle, swinging bucket, and vertical rotors for diverse separation needs.