Introduction

This article provides an in-depth exploration of mezzanines.

You will learn about:

- The definition of a mezzanine

- Common applications of mezzanines

- Installation procedures for mezzanines

- Key facts about mezzanines

- Relevant building codes

- And more...

Chapter One – What is a Mezzanine?

A mezzanine is an intermediate level located between a building's main floor and ceiling. Typically partially open to the floor below, it features a lower ceiling and covers only part of the main space. Mezzanines can be freestanding, ceiling-suspended, or permanently built into the structure.

Often considered as the floor above ground level, mezzanines serve multiple purposes as either permanent or temporary installations. They provide additional space for offices, storage, or work platforms and can be configured in various locations, from outdoor access platforms to interior workspace expansions.

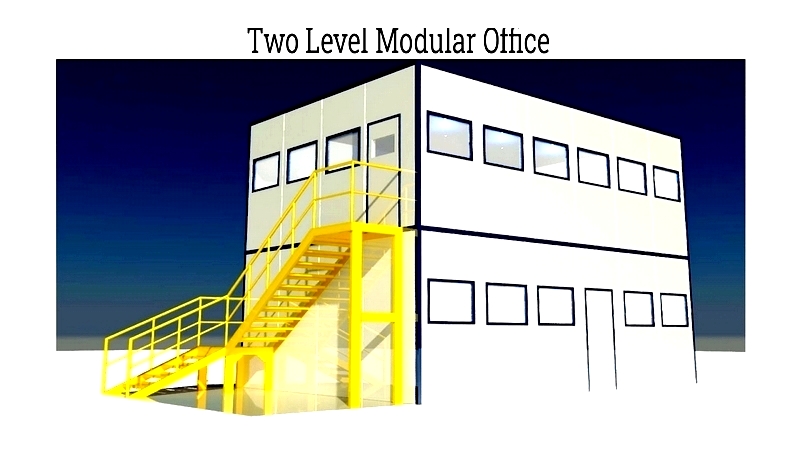

Freestanding mezzanines, as shown in the diagram below, offer flexibility as they can be easily dismantled and relocated.

The term "mezzanine" applies to both permanent and temporary structures. Permanent mezzanines are constructed with materials like concrete and steel as part of a building's original framework, included in building inspections and classifications.

Temporary mezzanine decks or work platforms are installed post-construction to meet growing space needs. These are considered equipment rather than structural components.

Permanent mezzanines appear in building inspection reports and may require additional infrastructure like elevators, affecting tax assessments. Temporary mezzanines are classified as equipment in inspection reports.

Despite being temporary, mezzanines are built with durable materials including various steel types, fiberglass, or aluminum. Flooring options range from finished wood to steel grating.

Commonly used by growing companies, mezzanines provide cost-effective space solutions, effectively doubling usable floor area. They're frequently installed in warehouses and factories with high ceilings to utilize vertical space.

Industrial mezzanines come in structural, roll-formed, rack-supported, or shelf-supported designs to meet diverse storage needs.

Chapter Two – Types of Mezzanines

When planning mezzanine installation, understanding load requirements ensures safety and functionality. Custom-designed mezzanine floors use materials suited to their application and weight capacity. Lightweight aluminum or fiberglass mezzanines work well for offices or light storage, while steel variants support heavy equipment and industrial use. Proper material selection ensures durability, space optimization, and compliance with safety regulations.

Types of Mezzanines

Freestanding Mezzanines

These self-supporting structures don't rely on building frames, offering flexibility for warehouse expansion. Supported by anchored steel columns, they maximize floor space for inventory storage, assembly lines, or conveyor systems.

Shelving and Rack Supported Mezzanines

These systems use existing racks for support, expanding vertical storage without altering floor space. The integrated design maintains usable space below for pallet storage or fulfillment operations.

Catwalk Mezzanines

Designed for vertical space utilization, these provide access to high shelving and equipment. Supported by racks with possible additional columns, they improve picking efficiency and maintenance access in distribution centers and factories.

Serving as elevated walkways, catwalks access conveyors, machinery, and sorting systems, converting unused space into functional pathways.

Full Mat Mezzanines

These versatile platforms expand over existing storage systems, creating space for inventory, offices, or break rooms. Their retrofitting capability minimizes renovation needs.

Prefabricated Mezzanines

These modular systems offer quick installation with minimal disruption. Their adaptable design suits various applications from offices to observation decks, with assembly possible in days.

Unlike permanent structures, prefabricated mezzanines can be modified or relocated as needs change.

Roll Formed Mezzanines

Using light gauge steel, these cost-effective solutions suit lightweight storage needs in retail or commercial settings, allowing layout adjustments for seasonal changes.

Structural Steel Mezzanines

Built with heavy-duty steel, these support heavy machinery and high-volume goods in industrial settings. Their robust construction offers long-term durability and scalability, often paired with concrete flooring for enhanced performance.

Choosing the Right Mezzanine

Selection depends on load requirements, ceiling height, intended use, and growth plans. Consulting specialists ensures code compliance and optimal design. Many suppliers offer accessories like stairs and safety features for complete solutions.